39

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

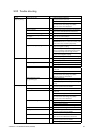

3.19.4 Checklist – Initial start-up

After thorough servicing or when the pump is to be put into service for the first time

(initial start-up) the following checklist must be observed:

Supply and discharge line

c Suction and discharge pipes are cleaned.

c Suction and discharge pipes are checked for leaks.

c Suction pipe is protected properly to prevent the ingress of foreign bodies.

Characteristics

c The characteristics of the pump unit and safety relief valve to be checked

(pumptype – see name plate, RPM, working pressure, effective power, working

temperature, direction of rotation, NPSHr etc.).

Electrical installation

c Electrical installation complies with local regulations

c Motor voltage corresponds with mains voltage. Check terminal board.

c Make sure that the starting torque is sufficiently high (no star/delta starting will be used).

c Motor protection is adjusted properly.

c Direction of motor rotation corresponds with direction of pump rotation.

c Motor rotation (detached from unit) is checked.

Safety relief valve

c Safety relief valve (on pump or in piping) is installed

c Safety relief valve is positioned correctly. Flow direction of safety relief valve

corresponds with suction and discharge lines.

c The set pressure of the safety relief valve is checked (see nameplate).

Jackets

c Jackets are installed.

c Maximum pressure and temperature of the heating/cooling media have been checked.

c The appropriate heating media or coolant is installed and connected.

c The installation complies with the safety standards.

Drive

c Alignment of pump, motor, gearbox etc. is checked.

Protection

c All guards and safety devices (coupling, rotating parts, excessive temperature) are in place

and operative.

c In case of pumps that may reach working temperatures of 60°C or more, ensure sufficient safety

guards against accidental contact re in place.

c Monitoring system is operational.

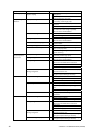

3.19.5 Start-up

When the pump is to be put into service the following checklist and procedure must be observed:

c Pump is filled with liquid.

c Pump is sufficiently preheated.

c Suction and discharge valves are fully open.

c Start the pump for a short while and check the direction of rotation of the motor and that the

magnetic coupling is not slipping.

c Start the pump and check suction of liquid (suction pressure).

c RPM of the pump is checked.

c Discharge pipe and seal are checked for leaks.

c Proper operation of the pump is verified.