Marley

/

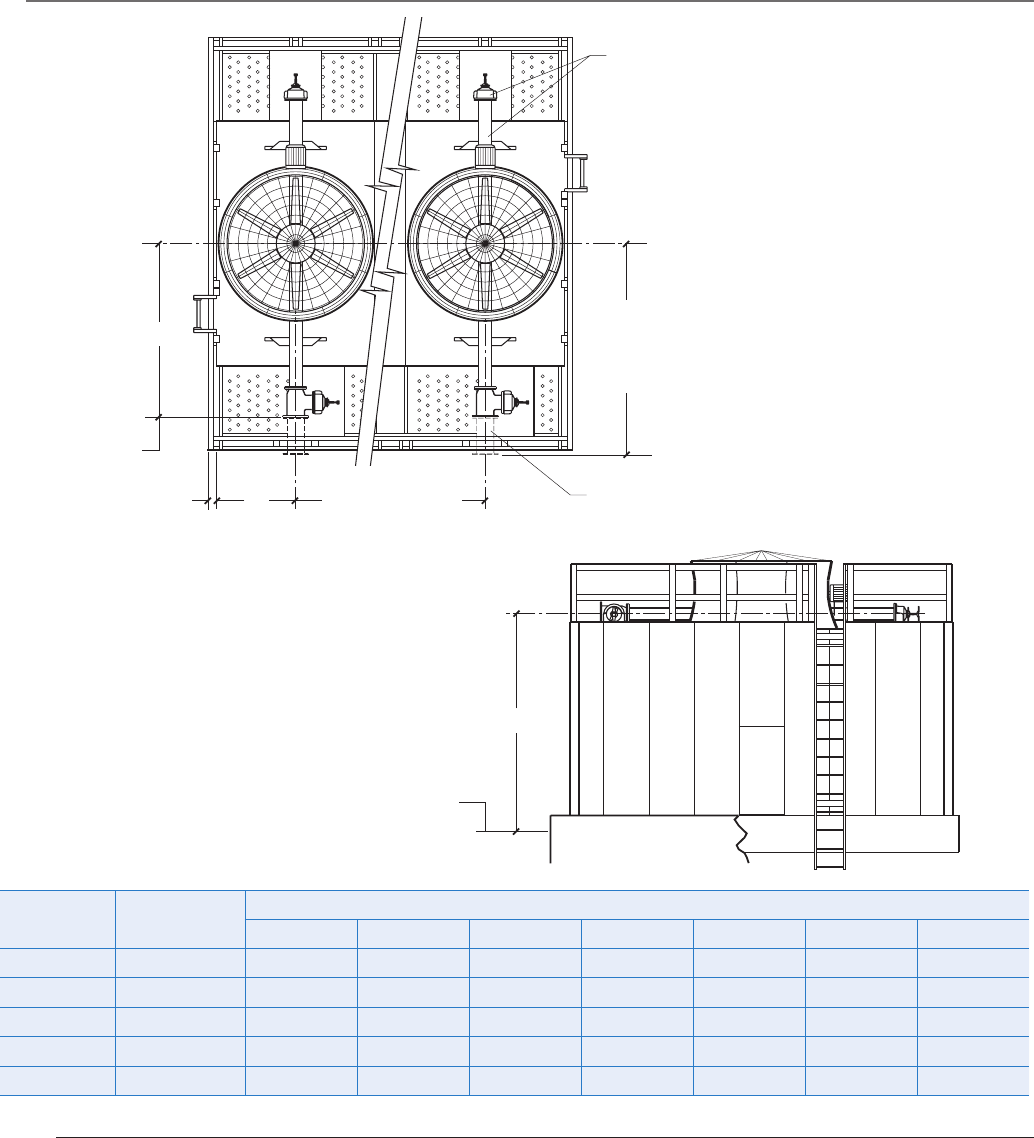

Sigma 1000 Cooling Tower

/

Engineering Data : Piping

5

F MINIMUM

C

L

INLET

C

L

COL.

C

C

L

INLET

D TYP. MULTI-CELL

PIPING SHOWN WITH

DASHED LINES IS BY OTHERS

E

FACE OF A DIA.

INLET PIPING

C

L

TOWER FAN

C

L

TOWER FAN

B DIA. FLOW CONTROL

VALVE AND CROSS OVER

PIPING

PLAN

G

BASE OF

TOWER COLUMNS

C

L

INLET

ENdwALL

ELEvAtioN

NotE

1 Use this bulletin for preliminary layouts only. Obtain current

drawings from your Marley sales representative.

2 Pumping head contributed by the tower is static lift shown

on page 5. Actual pumping head will vary according to tower

circulating GPM. Total pumping head will be furnished at time

of proposal.

3 If your application requires a bypass system, recommended

location is through tower endwall into plenum area. Review

of the system by SPX Cooling Technologies engineering is

required.

4 Marley piping terminates at face of a cast iron flat face flange

which conforms to class 125 lb ASME B 16.1 specifications.

5 Supports on tower for crossover piping are part of the tower

design. Do not support the riser’s dead load or operating load

from the tower. Do not brace the riser’s seismic or thrust

loads against the tower.

Tower

Model

GPM

per cell

Dimensions

A B C D E F G

1011 380 - 2140 10" 8" 4'-0" 8'-0"

8'-11

1

⁄8"

11'-8" 12'-5

7

⁄8"

1021 580 - 3220 10" 8" 6'-0" 12'-0"

8'-11

1

⁄8"

11'-8" 12'-5

7

⁄8"

1031 580 - 3220 10" 8" 6'-0" 12'-0"

10'-1

1

⁄8"

12'-10" 12'-5

7

⁄8"

1041 790 - 3240 10" 8" 8'-0" 16'-0"

11'-2

5

⁄8"

13'-11

1

⁄2" 12'-5

7

⁄8"

1041 3241 - 4300 16" 12" 8'-0" 16'-0"

11'-5

5

⁄8"

13'-11

1

⁄2" 12'-8

7

⁄8"