Specifications

Specification Value

Marley

/

Sigma 1000/1200 Cooling Tower

/

Specifications: Base

15

2.0 Thermal Performance:

2.1 The tower shall be capable of cooling

_____ GPM of water from ____ °F to

_____ °F at a design entering air wet-

bulb temperature of _____ °F. The cool-

ing tower manufacturer shall guarantee

that the tower supplied will meet

the specified performance conditions

when the tower is installed according

to plans.

2.2 The purchaser will arrange for an

on-site thermal performance test, to

be conducted in the presence of the

manufacturer and owner, and under

the supervision of a qualified, disinter-

ested third party in accordance with

CTI (Cooling Technology Institute) ATC-

105 standards during the first full year

of operation. If the tower fails to per-

form within the limits of test tolerance,

then the cooling tower manufacturer

will install additional cells and/or make

such corrections as are agreeable to

the owner and shall pay for the cost of

a retest. If the tower still fails to per-

form as specified, then the manufac-

turer shall make such reimbursements

as are appropriate and agreeable to the

owner to compensate for the perfor-

mance deficiency.

■ Your reason for purchasing a cooling tower is to obtain a con-

tinuing flow of cooled water as defined in the first paragraph at

left. If the tower that you purchase is incapable of performing

as specified, then you will not have received full value for your

money.

Bear in mind that the size—and cost—of a cooling tower var-

ies directly with its true thermal capability. This paragraph is

intended to protect you against either intentional or inadvertent

under sizing of the tower by the manufacturer. Judging the level

of performance of a cooling tower on critical processes is never

easy, and the potential risk of a non-performing cooling tower

usually causes the requirement for a mandatory acceptance test

to be very desirable.

Your contract with the successful bidder should establish the

acceptable remedies for missed performance, which might

include:

• The addition of one or more cells of tower, as necessary, to

bring the cooling tower to the specified level of performance.

This is usually limited to the scope of work as defined in the

specs, which means that you (the owner) will have to pay for

the additional basin, wiring, starters, piping, etc.

• The reimbursement of a portion of the total contract price equal

to the percentage deficiency in performance.

Under no circumstances should you allow the manufacturer to

re-pitch the fans to increase motor brake horsepower above that

shown in the proposal. That creates additional operating costs

that will continue for the life of the tower—and imposes no pen-

alty on the manufacturer.

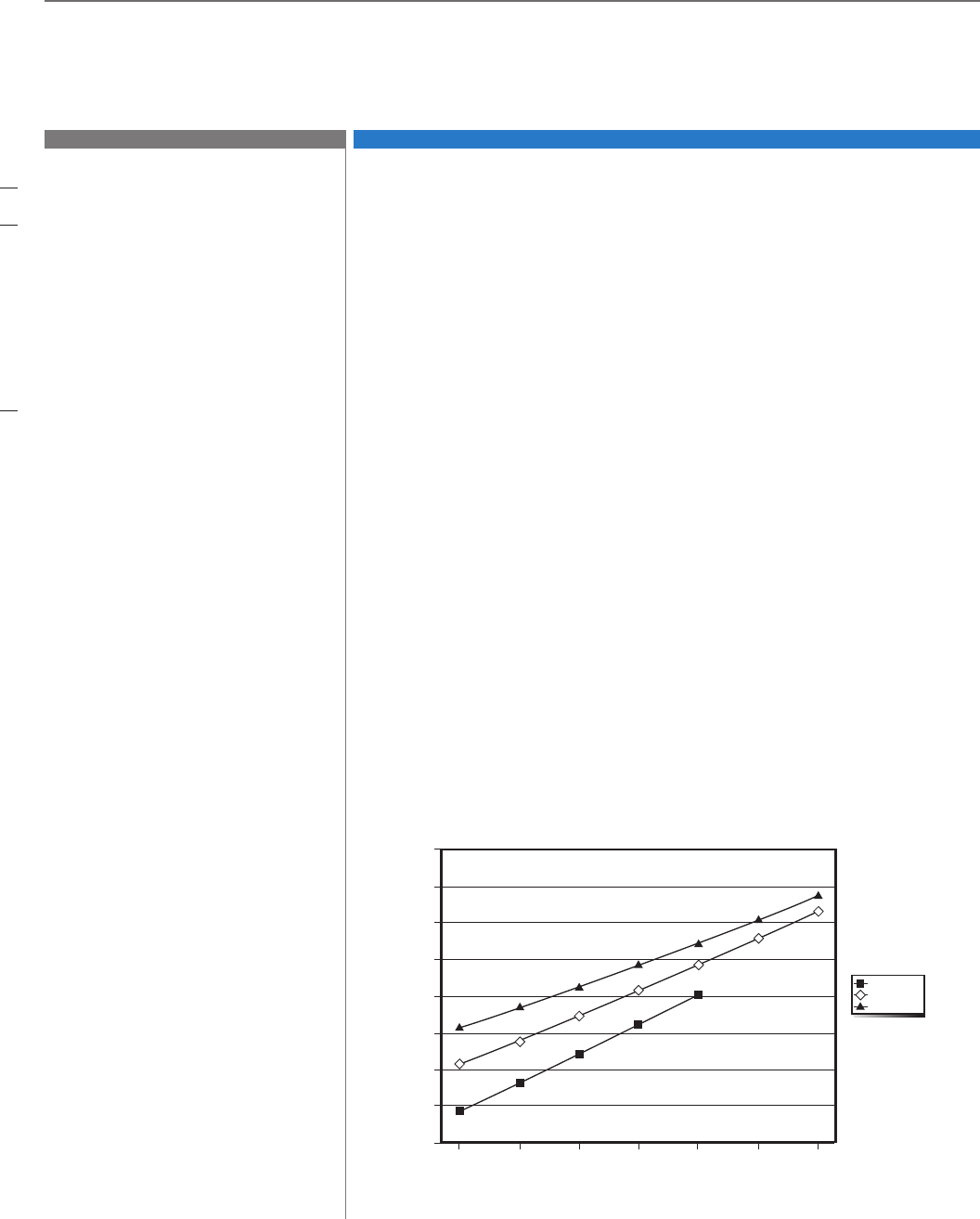

Typical cooling tower performance curve.

55°

50° 55° 60° 65° 70° 75° 80°

5°F RANGE

10°F RANGE

15°F RANGE

60°

65°

70°

75°

COLD WATER TEMP. (°F)

WET BULB TEMP. (°F)

80°

85°

90°

95°