Specifications

Specification Value

Marley

/

Sigma 1000/1200 Cooling Tower

/

Specifications: Base

19

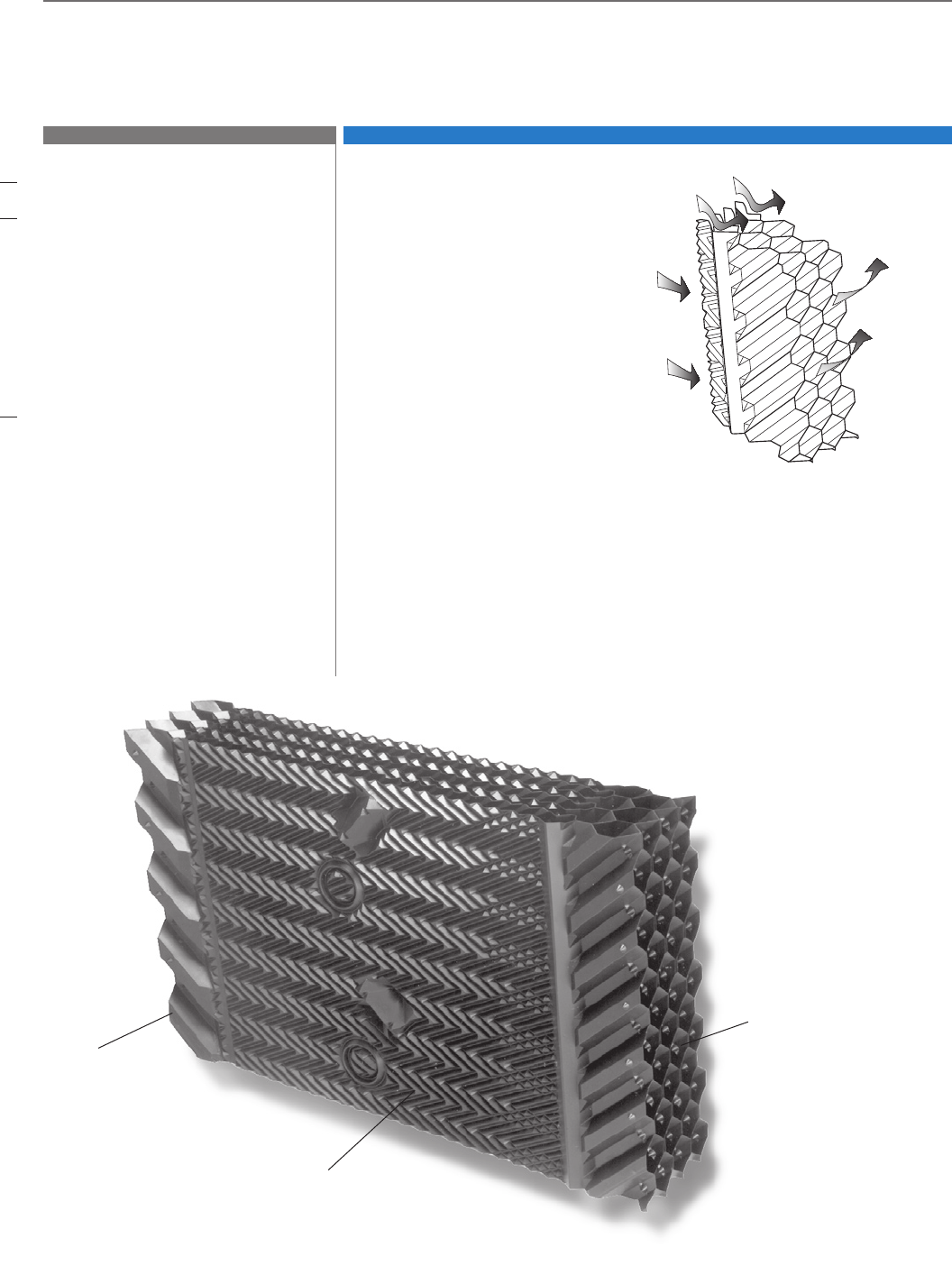

6.0 Fill, Louvers and Drift Eliminators:

6.1 Fill shall be film-type, 15 mil thick,

thermoformed PVC, with louvers

formed as part of each fill sheet. Fill

shall be suspended from stainless

steel structural tubing supported from

the upper tower structure, and shall

be elevated above the floor of the cold

water basin to facilitate cleaning. Air

inlet faces of the tower shall be free of

water splash-out.

6.2 Drift eliminators shall be PVC, triple-

pass, and shall limit drift losses to no

more than 0.010% of the design GPM

flow rate.

■ Louvers integral with the fill

keep the flowing water within

the confines of the fill. The sep-

arate external louvers used by

others permit water to escape

the fill and form ice or produce

an unsightly situation adjacent

to the tower. If you plan to use

your tower in the wintertime,

particularly for free cooling,

integral louvers will put your

operating concerns to rest.

Vertical blade-type eliminators, as

well as misdirected cellular types, cause

much of the fan power to be wasted in turn-

ing the horizontal flow of air vertical for its exit through the fan

cylinder. This power is, of course, not available for contribution to

thermal performance.

Drift rate varies with design water loading and air rate, as well

as drift eliminator depth and number of directional changes. The

indicated rate of 0.010% or less is easily achievable without pre-

mium cost. If a lower rate is required, please discuss with your

Marley sales representative.

Louver

Section

Drift Eliminator

Section

Fill Section