5

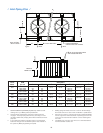

The primary structural elements of all Class 160 towers

are the nominal 4″ x 4″ columns spaced on 4′-0″ longitudinal

centers. A system of nominal 4″ x 4″ tower diagonals carries

loads in both tension and compression to heavy-duty hot dip

galvanized steel anchor plates.

Pressure-treated Douglas Fir is the standard material for

structural members in Class 160 towers because it offers

predictably consistent structural strength and provides long

service life in cooling towers.

Unless otherwise specied, all lumber is pressure treated

after fabrication. Treatment in accordance with CTI Standard

STD-112 is available on request.

All structural framing connections use ¹⁄₂″ diameter

galvanized machine bolts with either ber-reinforced nylon

shear connectors or FRP connector straps.

The fan deck is pressure treated exterior grade r plywood

designed for a uniform live load of 60 psf.

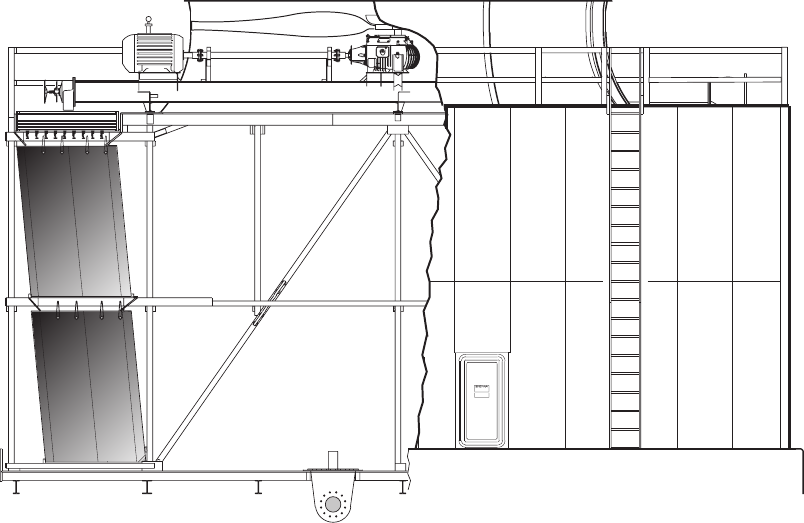

■ Access and Safety

The Class 160 tower is designed to meet all OSHA

requirements. A 3′-6″ high guardrail system complete with top

rails, intermediate rails and toeboards, surrounds the entire top

perimeter of the tower.

Aluminum ladders attached to the tower endwalls provide

access to the fan deck level. Ladders begin at the cold water

basin level and end at the top of the guardrail around the fan

deck. Each tower normally includes two ladders—one at each

endwall.

Hinged doors through the endwall casing permit access to

the interior of the tower at the basin level. Single-cell towers

have one door. Multicell towers have doors in both endwalls,

plus accessways through any and all partition walls.

All mechanical equipment is accessible both from the

interior of the tower and through the fan cylinder. Every

component of every tower is removable and replaceable.

■ Casing

Tower endwalls are cased with gray 8 oz/sq ft ribbed FRP

sheets. Water and corrosion-proof FRP is immune to biological

deterioration and requires no maintenance.

Casing ribs run vertically. Vertical joints between sheets

are overlapped one rib and are sealed in the ll areas. Casing

attaches to the structural members with stainless steel

fasteners and neoprene bonded washers. Corner trim pieces

are 12 oz/sq ft molded FRP.

■ Cold Water Basin

Most Class 160 owners install their towers over concrete

cold water basins provided by others—or you can choose a

wood collection basin as an option. See page 11.

Consult your Marley sales representative for detailed

dimensional drawings and load schedules to help you with

your basin design.