4

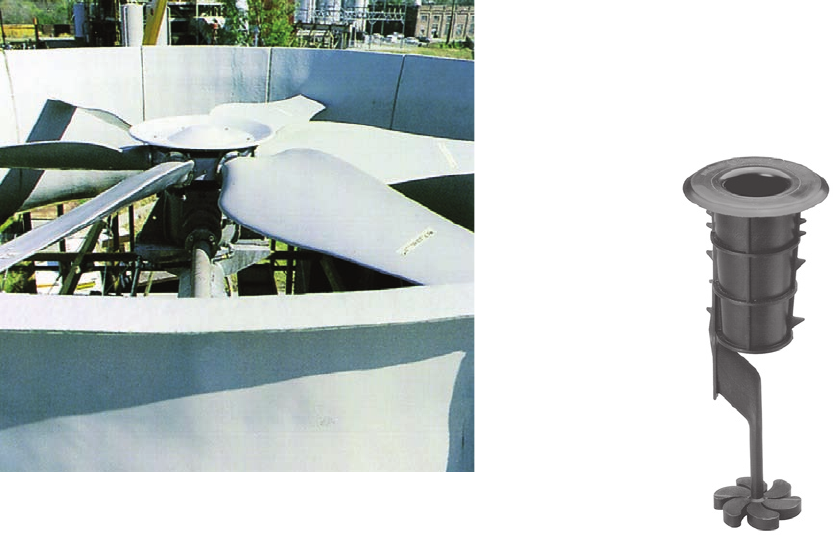

Class 160 towers offer the benets of adjustable pitch

propeller type fans. All fans used on Class 160 towers include

hollow GRE (glass-reinforced epoxy) blades and epoxy-coated

cast iron or galvanized steel hubs. Blades are adjustable in

pitch, so you can take full advantage of rated horsepower or

adjust the pitch to compensate for unusual jobsite restrictions.

The true airfoil blades, designed specically for cooling towers,

offer efcient, quiet operation and long service life.

■ Water Distribution System

The gravity-ow water distribution system designed into the

Class 160 tower essentially reduces pump head to its most

basic component—static lift—saving you money on pump

power. You won’t have to force water through internal piping

and pressure spray nozzles, as you would in a counterow

tower.

Warm water enters the system through a Marley galvanized

crossover pipe. Inlet connections for your piping are drilled to

conform to Class 125 ANSI requirements. Marley ow-control

valves balance the ow to both distribution basins of each

cell. Water ows from the valves through a splash-suppression

chamber and into the treated r plywood distribution basins.

Polypropylene Marley “Spiral Target” nozzles in the basin

Fans operate inside structural FRP (ber-reinforced

polyester) eased-inlet fan cylinders designed and applied to

maximize fan performance. Standard cylinder heights are

6′-0″ to 7′-0″, depending on fan diameter. 10′-0″ cylinders are

available as an option.

Marley-manufactured driveshafts transmit power from the

motor to the Geareducer assembly. All Marley driveshafts

include 304 stainless steel tubes with welded-on stainless

steel anges and bonded neoprene exible elements to

transmit torque. Marley driveshafts are full-oating assemblies

with non-lubricated exible couplings on each end. Their

tolerance to misalignment and torsional shock is unequalled

in non-specialized units. All Marley driveshafts are dynamically

balanced at the factory to minimize operating vibrations.

Welded unitized hot dip galvanized steel supports maintain

alignment throughout the mechanical equipment system.

Marley torque-tubes provide superior strength and stability.

Their cylindrical shape also keeps operating costs down by

minimizing airow restrictions and reducing air turbulence in

the fan entrance region.

oor then distribute the water uniformly over the ll.

All materials in the water distribution system offer long life

and minimal maintenance. Valves consist of cast iron bodies

and grease-lubricated stainless steel operating stems. All

plywood is treated exterior grade. The nozzles are chemically

and biologically inert, so they’ll last indenitely.

■ Structure and Materials

Class 160 tower design conforms to the latest edition of

the National Design Specication for Wood Construction (NDS)

published by the National Forest Products Association, as well

as CTI standards STD-114 and STD-103. Wind load criterion

is normally 30 pounds per square foot of projected area and

the design meets criteria for UBC Zone 1 seismic loading,

based on a maximum water temperature of 120°F.