3

/ Construction and Components /

■ Fill/Louvers/Drift Eliminators

Marley high-performance lm ll is the heart of every Class

160 tower. A repeating chevron pattern provides the wetted

surface and air turbulence necessary for proper heat transfer,

while minimizing resistance to airow so you’ll save on fan

power. Molded protrusions on each ll sheet assure uniform

spacing.

Fill sheets are vacuum formed 15 mil (.015″) thick

PVC (polyvinyl chloride) capable of service at hot water

temperatures up to 120°F. Consult your Marley sales

representative for applications where hot water temperatures

are greater than 120°F yet less than 145°F to determine

upgrade possibilities. Stainless steel structural tubes resting in

stainless steel hangers support the ll, and PVC tubes control

alignment. This system also holds the bottom of the ll sheets

above the cold water basin oor to simplify basin cleaning.

Fill sheets include both louvers and drift eliminators. The

louvers in this patented arrangement keep water on the

ll sheets and in your tower, and also assure proper heat

transfer throughout wide variations in airow. Users nd this ll

operates ice-free even in extremely cold weather.

Integral drift eliminators prevent the costly nuisance of

drift spotting on objects in the sur round ing environment.

Their unique shape induces the air ow through three distinct

direction changes as shown below. The nal turn directs air

toward the fan to save you fan horsepower. Moisture carried

in the air stream can’t make these abrupt turns, so drift is less

than 0.005% of the circulating water ow rate.

■ Mechanical Equipment

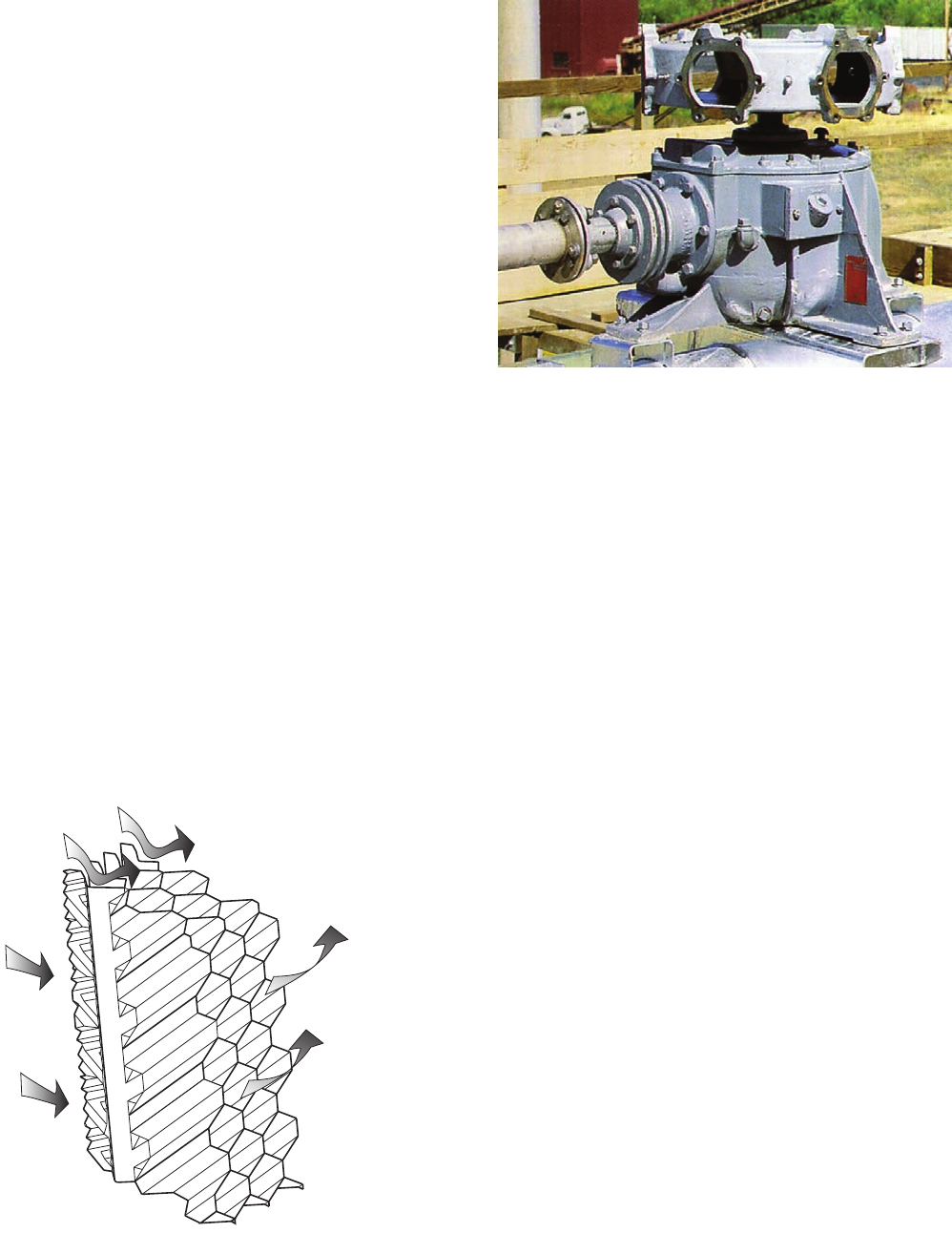

The Marley Geareducer speed reducer used in the Class

160 line contributes a long record of dependability, long service

life, and low maintenance. Their designs meet or exceed the

requirements of CTI STD-111 and AGMA Std. 420.04. We run-

in every Geareducer unit under load prior to shipment to make

sure that it will operate properly on your tower.

Housings are gray cast iron. Gears are high-strength,

case hardened alloy steel. And all bearings are tapered roller

bearings. A variety of available horsepower capacities and

reduction ratios lets us choose the optimum Geareducer model

and fan speed for your job. Service factors are always at least

2.0 as applied.

Splash-type lubrication and integral cooling ns preclude

the need for maintenance-intensive oil pumps and coolers. A

constant oil bath or ow lubricates every bearing in forward or

reverse motion—at full or half speed.

All Marley Geareducer assemblies are rightangle type with

motors located outside the tower’s saturated airstream.

A galvanized steel lube line runs from the Geareducer unit to

a standpipe near the motor on each cell, so you can check oil

level and change or add oil while standing on the fan deck.