19A SERIES BOILER

INSTALLATION INSTRUCTIONS

PAGE 8

15. CONTROL LOCATIONS

NOTE

Jacket front panel should be in place before controls on

front of front section are installed.

Refer to FIGURE 11 showing locations recommended for

steam and water boiler limit and operating controls. Note the

requirement for an operating temperature control whenever

a tankless heater is called for. This is in addition to pressure

limit controls and other operating controls on steam boilers.

NOTE

On steam boilers the 1" close nipple and 1" x 1/4"

reducing coupling for operating control should be installed

prior to jacket top panels.

16. JACKET

Jacket assembly details are contained in a separate instruction

booklet.

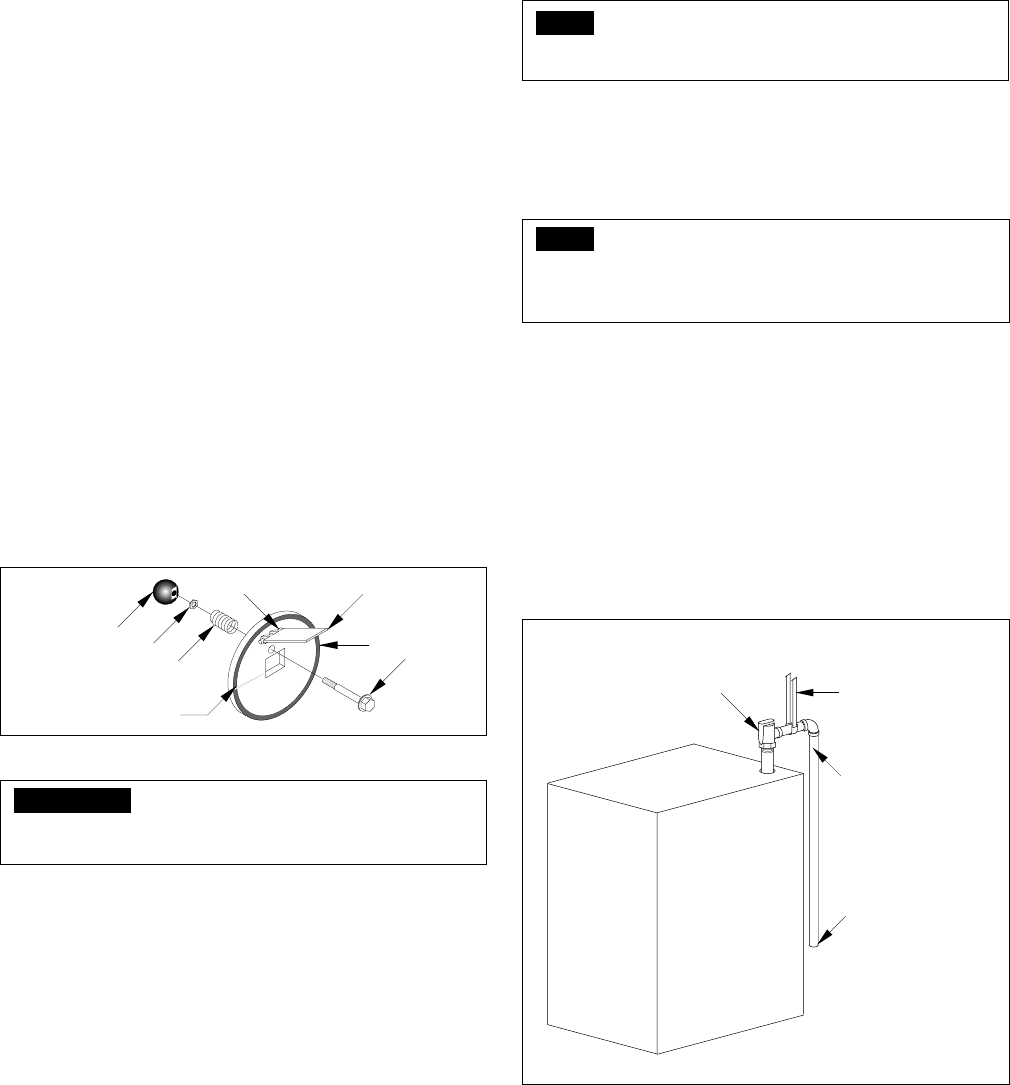

17. SAFETY AND RELIEF VALVES

Safety and relief valves sized on the output rating of each

boiler size are furnished along with the necessary pipe and

fittings for installation in the back section. The valve discharge

connections should be piped to a location where people will

not be exposed to hot vapor or liquid. Any discharge piping

should be supported so as to prevent exerting any strain on

the valve body by the weight of the piping. See FIGURE 10.

FIGURE 10

Some state and local codes require steam safety valves be

piped to the atmosphere outside the building.

13. CLEANOUT COVERS

Be sure the rope seals are in place around the groove in the

cleanout cover plate. Install the plates on the boiler sections

carefully to insure proper sealing all around, using the

5/16" x 2" special anchor bolt and 5/16" hex head nuts. After

periodic flue cleaning, replace nuts at 10 lbs. torque. Use

Hi-Temp silicone caulk to seal covers air-tight.

14. REAR OBSERVATION PORTS 7-12 SECTIONS

INSTRUCTIONS FOR ASSEMBLY:

1. Locate steel “flapper door” (Item 6) as shown in FIGURE

9 below. Drive Item 7, “expansion pin”, into hole in Item 1

to secure 6 in position.

2. Lift Item 6 up and install Item 2, “hex bolt”.

3. Slide Item 3, “compression spring” over the hex bolt and

screw Item 4 “hex nut” to hex bolt.

4. Screw Item 5, “ball knob” into position and lock location

using Item 4 as a “jam” nut.

5. Adhere 24-1/2" insulating tape as shown to Item 1.6.

Mount assembly to back section of boiler.

7. 3-6 section boilers use a solid cover which is installed the

same way.

FIGURE 9

IMPORTANT

Item 6 must always be part of the assembly. Check

condition twice a year and replace as needed.

1

2

3

4

5

7

6

INSULATING TAPE

FOR DISCHARGE PIPING THROUGH ROOF CONSULT THE SMITH COMPANY

DISCHARGE PIPE SIZE

TO EQUAL VALVE OUTLET.

DO NOT RESTRICT FLOW.

RELIEF OR SAFETY VALVE

DO NOT REMOVE RATING

OR WARNING TAGS.

SUPPORT DISCHARGE

PIPING SO AS TO AVOID

STRAIN ON VALVE BODY

DISCHARGE SO AS TO

AVOID EXPOSURE OF

PERSONS TO HOT

LIQUID OR VAPOR.

LEAVE OPEN END

VISIBLE FOR PERIODIC

INSPECTION FOR SLOW

LEAKAGE OR DRIPS.