TABLE 5

Feed water makeup requirements.

NOTE

These recommendations are considered normal for

compact buildings on the basis of 80% receiver use.

Where buildings are spread out, additional receiver

capacity may be necessary because of the extended

time required for condensation to return to the receiver.

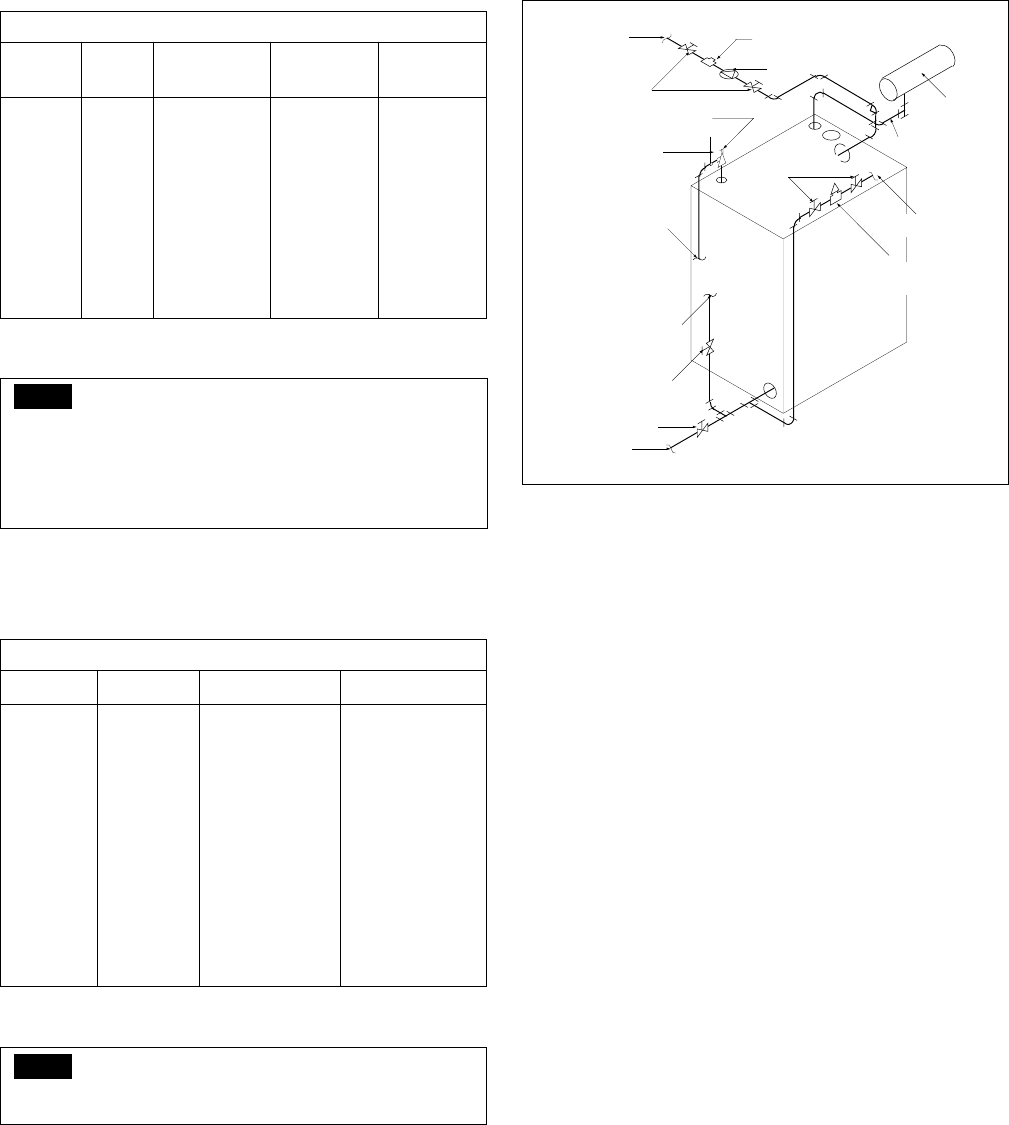

9. WATER PIPING

See FIGURE 5 for acceptable water piping diagram. TABLE

6 gives pumping rate and supply & return sizing for standard

installations.

TABLE 6

Based on 20°F system temperature drop.

NOTE

Boiler supplied with 4" water supply tapping and 3" return

tapping.

FIGURE 5

10. TANKLESS HEATERS

Heater openings are provided for below-the-water-line tankless

heater coils in all special intermediate sections when ordered.

See TABLE 2 for the conr•ct placement of these heater

sections. Install the low limit temperature control in the 3/4"

tap located in the center of the coil.

If the heater sections are installed in an order other than in

TABLE 2 the jacket panels will not match.

11. SMOKE HOOD

Install smoke hood with the correct size smoke pipe

connecting collar using the 5/16" x 1-1/2" studs and hex nuts

furnished in screw seats in the back section. Apply self-

adhesive insulating tape (Items 21 and 22 in Parts detail

drawing on Page 2) to smoke hood flange and damper angle

Item 23. Fasten the slide damper in the open position for

starting the burner adjustment process.

See FIGURE 6 for recommended “L” coil piping and FIGURE

7 for SM9-18 single and/or dual piping arrangements.

19A SERIES BOILER

INSTALLATION INSTRUCTIONS

PAGE 6

3

4

5

6

7

8

9

10

11

12

.61

.85

1.19

1.52

1.86

2.19

2.53

2.86

3.20

3.53

1.4

1.9

2.4

2.9

3.3

3.8

4.3

4.8

5.2

5.7

1.22

1.70

2.37

3.04

3.71

4.38

5.05

5.72

6.39

7.06

12

16

22

29

35

41

47

54

60

66

NUMBER

OF

SECTIONS

EVAPOR.

RATE

GPM

WATER 1"

BELOW WATER

LEVEL GAL.

MIN. FEED

WATER PUMP

RATE-GPM

CONDENSATE

RECEIVER

CAP.-GAL.

BOILER SIZE GPM RETURN CONN. SUPPLY CONN.

3

4

5

6

7

8

9

10

11

12

30

41

58

74

90

106

123

139

155

171

2"

2"

2-1/2"

3"

3"

3"

3"

3"

3"

3"

2"

2"

2-1/2"

3"

3"

3"

3"

3"

4"

4"

GATE VALVE

SUPPORT RELIEF VALVE

DISCHARGE PIPE

TERMINATE DISCHARGE

PIPE SO AS TO AVOID

DISCHARGE ON PERSONS

SYSTEM RETURN

CONNECTION

BLOWDOWN VALVE

TO DRAIN

GATE VALVE

TYPICAL WATER PIPING DIAGRAM

RELIEF VALVE

PRESSURE

REGULATING

VALVE

GATE

VALVE

CIRCULATOR

EXPANSION

TANK

AIR REMOVAL

PIPING

CHECK VALVE

C.W. MAKEUP

CONNECTION

SYSTEM SUPPLY

CONNECTIONS