VI

CTORY VSPH Models

18

2. Power Connection

A. Remove electrical junction box cover.

B. Hot connection lead is black. Neutral connection lead is white.

Proper polarity is important for VSPH boilers. Reversed

polarity will cause system lockout and the power LED will

flash continuously.

C. Connect ground wire to ground screw inside the junction box.

D. Replace junction box cover.

THERMOSTAT CONNECTIONS

Install thermostat on an inside wall and away from any heat

sources, sunshine and drafts.Thermostat wires must be connect-

ed to terminals block on boiler. See wiring diagram Figure 13a.

Thermostat heat anticipator: For a non-zoned system set thermo-

stat heat anticipator to 0.4 Amps, for zoned system set to match

power requirements of zone valves or relays. Refer to manufactur-

er’s instructions and specifications. Also see instructions with ther-

mostat.

MULTI ZONING

For multiple zoning, either zone valves or circulators maybe used.

For zone valve system see Figure 14.

For pump zoning system see Figure 15 and Figure 16.

DO NOT use boiler transformer to power external accessories like

zone valve and relays, overload and/or burned-out transformer

and boiler malfunction can result. Use separate transformer to

power such components. For pump zoning system, remove boiler

circulator wire connector from P5 of electronic boiler control (See

Figure 13b).

WATER PIPING

Always follow good piping practices. Observe minimum 1" clear-

ance to combustibles around all uninsulated hot water pipes or

when openings around pipes are not protected by non-com-

bustible materials.

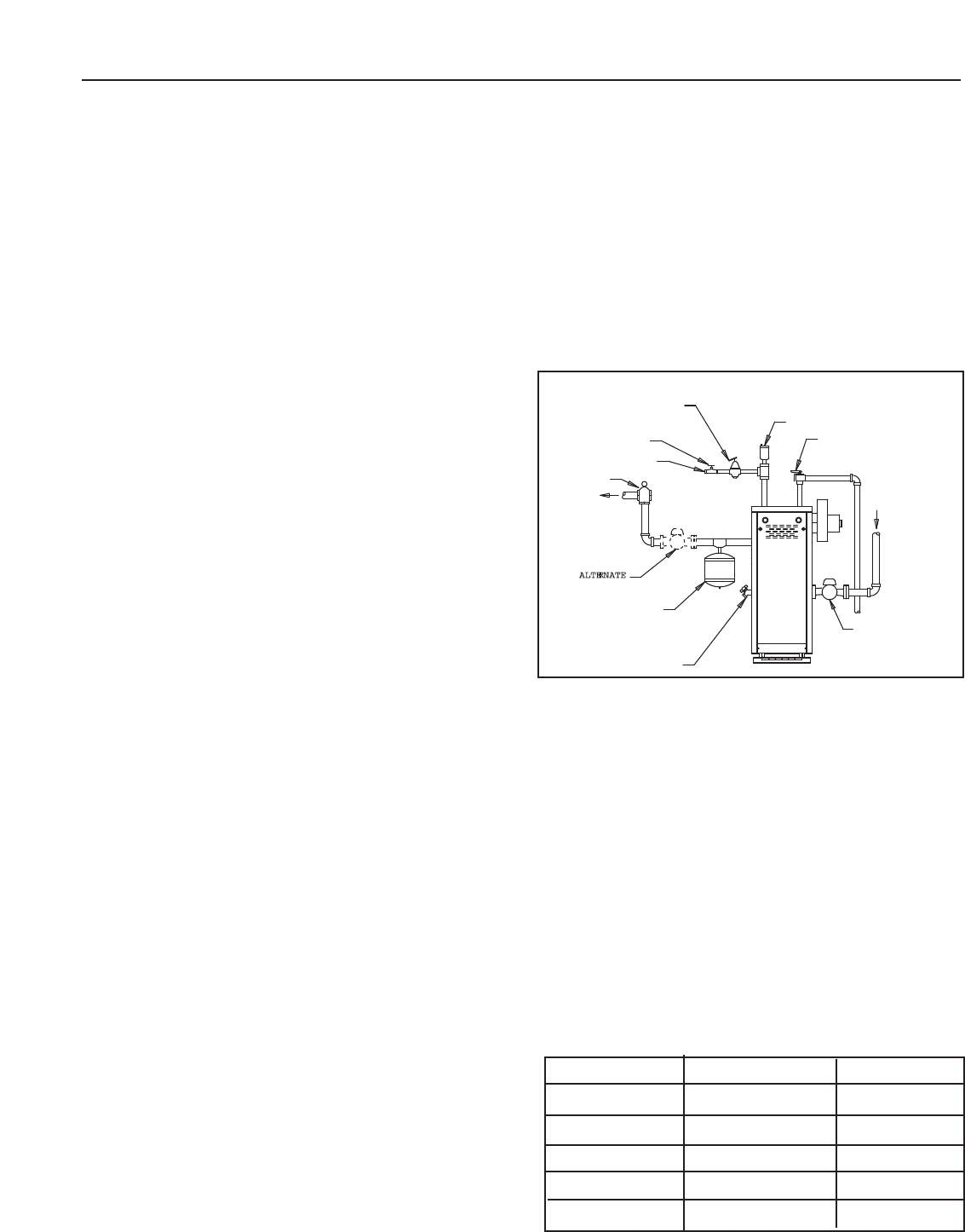

On a hot water boiler installed above radiation level, the boiler

must be provided with a low water cutoff device at the the time of

installation by the installer (see Figure 17 for piping arrangement).

The low water cutoff must be wired in series with rollout safety

switch and Aquastat (limit control). See wiring diagram Figure

13a.

1

1

.

.

Supply and Return

For tapping sizes see dimensions on page 2. Shut-off valves

are recommended.

2

2

.

.

C

irculating Systems

Victory VSPH boilers are equipped with a water circulating

pump mounted to the return water connection on the boiler.This

p

ump location is appropriate for most installations. It may be

desired and proper to locate this pump to the alternate location

shown in Figure 17, especially when applied to larger systems

using high-head pumps.

When the pump is removed there is a 1

1

⁄2” FPT tapping that the

r

eturn pipe may be attached to.

At one month intervals after the last call for heat, the circulator

will be energized for 30 seconds. Short operation after long term

i

dle periods prevent damage of the pump from sedimentation.

3

3

.

.

Radiant Floor, Low Water Temperature and large water

volume systems

A boiler by-pass loop, three way valve arrangement, or

primary secondary pumping (with a boiler loop) must be

used to provide a minumum 130˚ return water temperature

to the boiler.This will prevent condensation on the cast-iron

sections that can result in improper operation of the boiler.

4

4

.

.

Air control system

Diaphragm type compression tank is used to control system

pressure. It must be installed at the boiler or between boiler

and supply main pump(s).

An automatic air vent is used to remove air from the system

in Figure 17. If system pressure needs further control, add

an additional tank in parallel with original tank or install a

larger capacity tank. Use appropriate size tank for volume of

water in system. See chart for boiler’s volume.

Model Pounds Gallons

VSPH-60 24.75 3.0

VSPH-90 32.00 3.8

VSPH-120 39.25 4.7

VSPH-150 46.50 5.6

VSPH-180 53.75 6.4

Boiler Water Content

GATE VALVEGATE VALVE

FACTORYFACTORY

CIRCULATORCIRCULATOR

LOCATIONLOCATION

3/4" PRESSURE3/4" PRESSURE

RELIEF VALVERELIEF VALVE

AIR VENTAIR VENT

RETURNRETURN

SUPPLYSUPPLY

EXPANSIONEXPANSION

TANKTANK

ALTERNATE

CIRCULATORCIRCULATOR

LOLOCATCATIONION

FLOW CONTROLFLOW CONTROL

VALVEVALVE

WATER FEEDWATER FEED

PRESSUREPRESSURE

REDUCINGREDUCING

(FILL)VALVE(FILL)VALVE

DRAIN COCKDRAIN COCK

Figure 17. Piping arrangement