Unit 9

Lubricating greases

2727

9. Lubrication greases

SANDEX units use an oil bath lubricating system. In certain mounting positions, the bearings sit

above the oil level. In this case, a sealed lubricating device is installed exclusively for the bearings and

grease nipples are attached wherever grease must be reapplied. Note, your SANDEX has already been

greased prior to initial operation. Apply grease every 2000 to 4000 hours of operation.

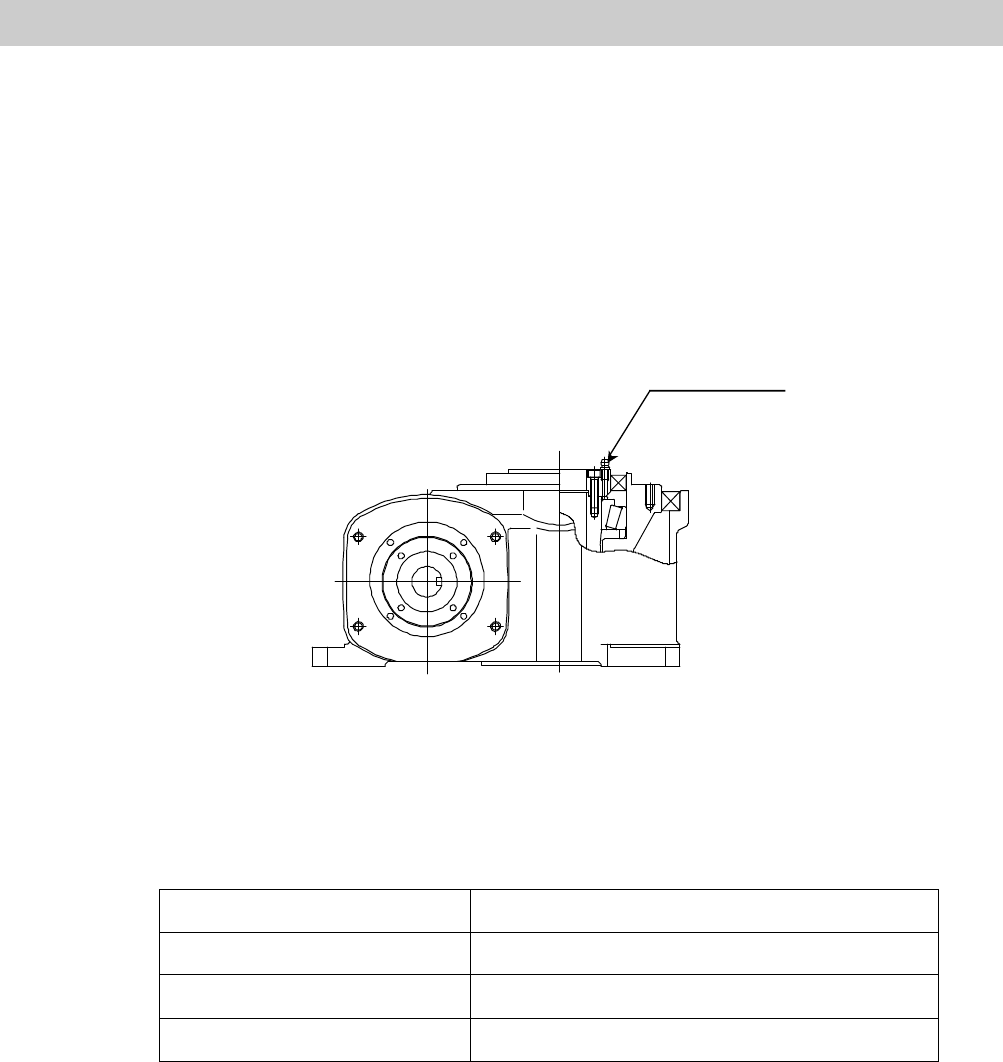

9.1 Supplying lubricating grease

(1) If the mounting position of the Alpha index output flange is horizontal, parallel to

the ground, grease needs to be applied to the bearing by the grease fitting supplied

on the output stationary flange.

(2) Supply 5 to 30 g per shot according to the SANDEX model you are using. Old

grease will fall into the oil basin and will be drained when the lubricating oil is

replaced.

Recommended lubricating greases

MAKER LUBRICATING GREASE LABELS

Esso Standard Oil Beacon 2, Q2 ; Lystan 2, EP2

Shell Oil Alvania 2, EP2

Mobil Oil Mobilax Grease 2, EP2

Grease nipples