Regency P48 Zero Clearance Direct Vent Gas Fireplace 21

INSTALLATION

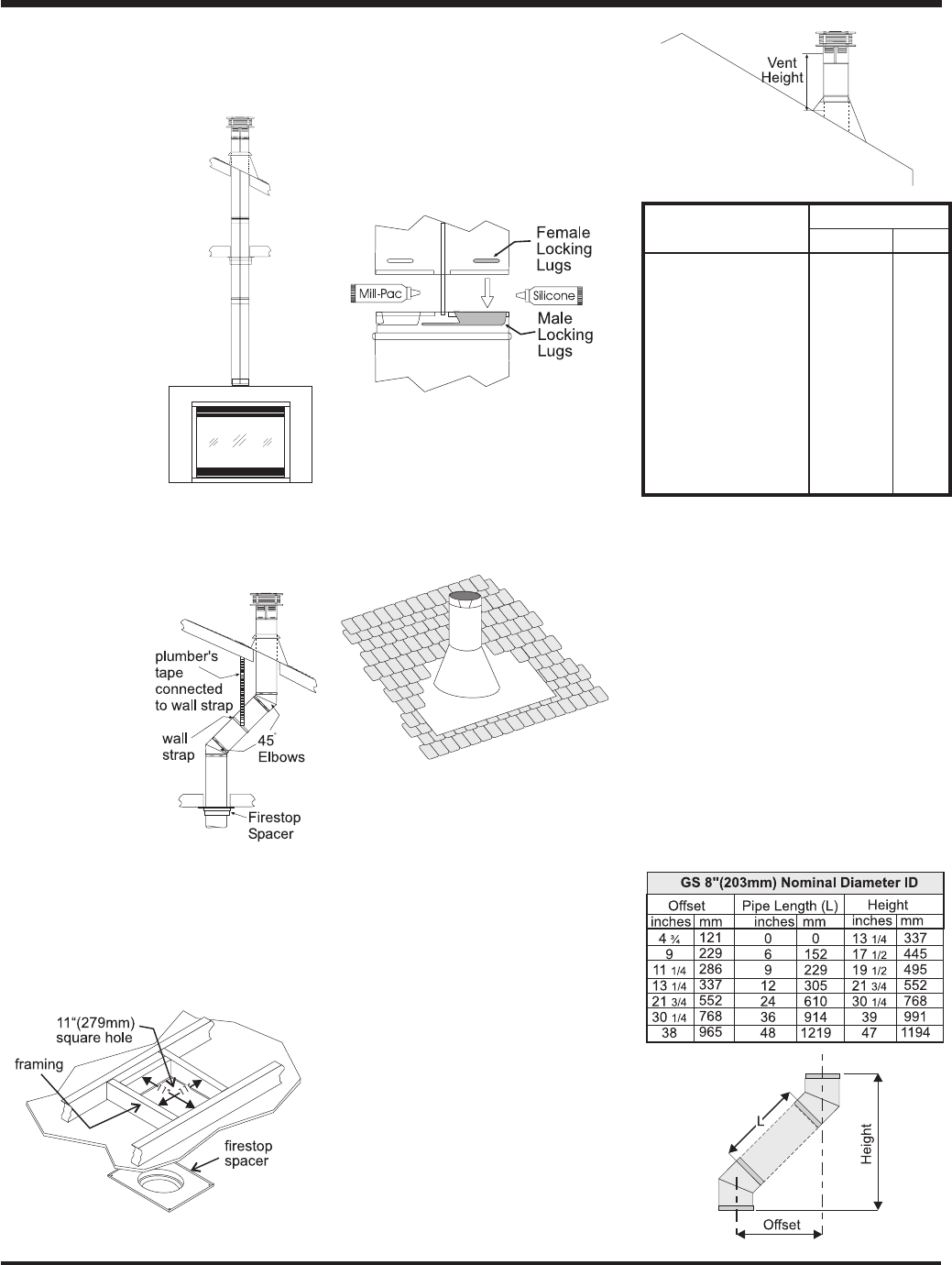

6) Continue to assemble pipe lengths.

Note: If an offset is necessary in the attic

to avoid obstructions, it is impor-

tant to support the vent pipe every

3 feet (0.9 meter), to avoid exces-

sive stress on the elbows, and

possible separation. Wall straps

are available for this purpose

(Diagram 2).

Galvanized pipe is desirable above the roof-

line due to its higher corrosion resistance.

Continue to add pipe sections through the

flashing until the height of the vent cap meets

the minimum height requirements specified in

Diagram 5 or local codes. Note that for steep

roof pitches, the vertical height must be in-

creased.

Diagram 3

Note:

Apply sealant "Mill-Pac" to inner pipe and

high temp silicone sealant to outer pipe

on every twist-lock joint.

VERTICAL

TERMINATION

1) Maintain the 1-1/4"(32mm)

clearances (air spaces) to

combustibles when pass-

ing through ceilings, walls,

roofs, enclosures, attic raft-

er, or other nearby combusti-

ble surfaces. Do not pack air

spaces with insulation.

Check pages 16-17 for the

maximum vertical rise of the

venting system and the maxi-

mum horizontal offset limita-

tions.

2) Set the gas appliance in its

desired location. Drop

a plumb bob down

from the ceiling to the

position of the appli-

ance flue exit, and

mark the location

where the vent will

penetrate the ceiling. Drill a small hole at his

point. Next, drop a plumb bob from the roof

to the hole previously drilled in the ceiling,

and mark the spot where the vent will

penetrate the roof. Determine if ceiling joists,

roof rafters or other framing will

obstruct the venting system. You

may wish to relo-

cate the appliance

or to offset, as

shown in Diagram

2 to avoid cutting

load bearing mem-

bers.

3) A Firestop spacer must be installed in the

floor or ceiling of every level. To install the

Firestop spacer in a flat ceiling or wall, cut

a 11 inch (279mm) square hole. Frame the

hole as shown in Diagram 3 and install the

firestop.

4) Assemble the desired lengths of pipe and

elbows. Ensure that all pipes and elbow

connections are in the fully twist-locked

position and sealed.

Diagram 4: The upper half of the flashing is

installed under the roofing material and not

nailed down until the chimney is installed.

This allows for small adjustments.

5) Cut a hole in the roof centered on the small

drilled hole placed in the roof in Step 2. The

hole should be of sufficient size to meet the

minimum requirements for clearance to

combustibles of 1-1/4"(32mm). Slip the

flashing under the shingles (shingles should

overlap half the flashing) as per Diagram 4.

Diagram 2

Offset Chart

A poor draft, or down drafting can result from

high wind conditions near big trees or adjoin-

ing roof lines, in these cases, increasing the

vent height may solve the problem.

7) Ensure vent is vertical and secure the base

of the flashing to the roof with roofing rails,

slide storm collar over the pipe section and

seal with a mastic.

8) Install the vertical termination cap by twist-

locking it.

Note: Any closets or storage spaces,

which the vent passes through

must be enclosed.

Diagram 5

Roof Pitch Minimum Vent Height

Feet Meters

flat to 7/12 2 0.61

over 7/12 to 8/12 2 0.61

over 8/12 to 9/12 2 0.61

over 9/12 to 10/12 2.5 0.76

over 10/12 to 11/12 3.25 0.99

over 11/12 to 12/12 4 1.22

over 12/12 to 14/12 5 1.52

over 14/12 to 16/12 6 1.83

over 16/12 to 18/12 7 2.13

over 18/12 to 20/12 7.5 2.29

over 20/12 to 21/12 8 2.44

Diagram 1