8"

2 LB

CHEMICAL

RESISTANT

CHECK VALVE

Part# 888-018

LOOP ABOVE

TO

POOL

CHLORI-

NATOR

FROM

HEATER

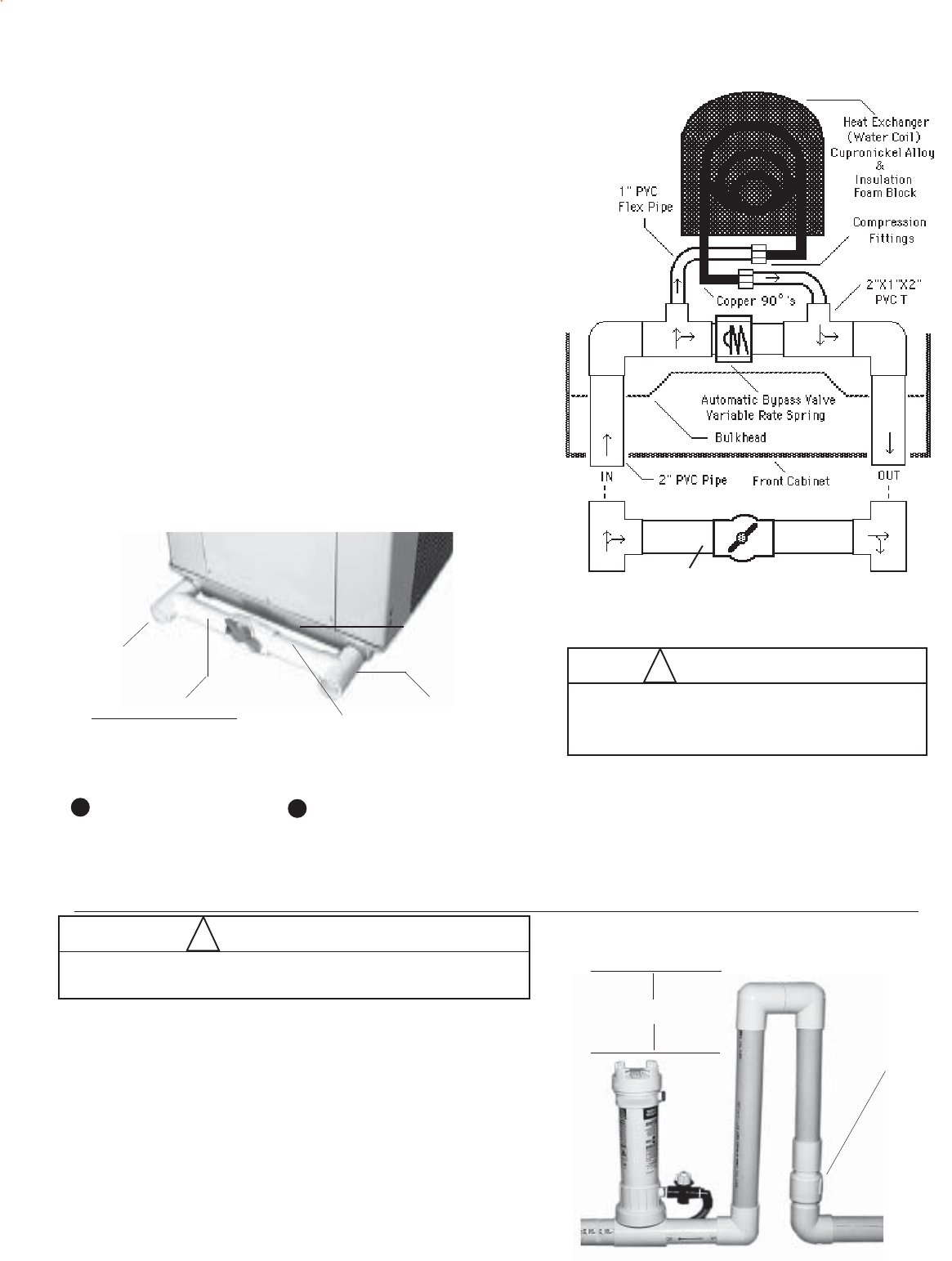

The chemical resistant check valve and loop must be in-

stalled with all types of chlorinators to prevent chlorine

migration to the heater. The loop should extend at least 8

inches above the chlorinator top. The chemical resistant check

valve should be placed on the pipe leading "up" to the chlo-

rinator. Therefore, the weight of the water above the check

valve will hold it closed even if the spring is weak or dam-

aged. Mount it as low as possible. Be sure to keep the chlo-

rinator, pump and filter lid o-rings lubricated with silicone

grease to insure a good seal. If it looses its seal, it will allow

the chlorine to migrate to the heater when the system shuts

off. The loss of vacuum allows reverse flow.

19

"Excessive Flow Valve Manifold"

Do not valve in a manner that will totally

isolate heater from water flow see page 25.

EXCESSIVE FLOW BYPASS MANIFOLD FOR LARGE

2 H.P. PUMPS OR OVER 90 G.P.M.

If the pool circulation pump is over 2 HP OR if the total

flow exceeds 90 GPM you will have to add the "excessive

flow valve" as shown here. Do not install a bypass valve

that will completely shut off flow to the heater, see shut-

down procedures.

Some larger water pumps may be restricted if the pipe size is

not adequate therefore reducing its overall flow rate. When

determining if you need an excessive bypass valve, one has to

consider the hydraulic restriction of the filter, valving, amount

of 90½ fittings and the distance of pipe to the pool in the exist-

ing filtering system. If you have a 2 HP water pump that does

not exceed 90 G.P.M. considering the above, you may not need

the excessive bypass. Excessive water flow can damage the

heat exchanger. SPECIAL NOTE: See chlorinator place-

ment instructions at the bottom of this page.

HIGH RATE WATER PUMPS

Ball Valve

@ 45 Deg.

Bypass Pipe Size:

1.5" or 2" pipe @ 2 H.P.

2" pipe @ 3 +.H.P

2" p.v.c. "T"

2" p.v.c. "T"

All others must be set by flow meter.

See Commercial Plumbing Diagram

2 H.P Pumps

Close Bypass 50%

3 H.P. Pumps

Close Bypass 25%

BE SURE THE BYPASS VALVE IS

POSITIONED TO ALLOW REMOVAL

OF THE FRONT ACCESS PANEL!

Position the valve so that the access panel can be

easily removed, always check before final glu-

ing. Angle the valve out 45" to provide adequate

clearance. You may use a 2-way valve or other

type if desired. "Do not" use a brass gate valve

or a 3-way valve for bypass !

Exercise care when installing chemical feeders so as not to allow

back siphoning of chemicals into the heater, filters or pump.

CAUTION

CAUTION

Place plumbing so

access panel can

be opened

!

!