FILTER CLEANING & CARE

Your filter system should be cleaned at least twice a

month. See manufacturer's directions for proper filter

cleaning methods. Size and conditions may require you

to clean the filter more often. A filter is considered

"dirty", whenever it restricts the flow rate by 10% or

more.

You can use the pressure gauge on the filter tank to de-

termine a restriction in the filter due to clogging. After

the filter has been replaced or when it is new, you should

record the actual operating pressure with a "clean fil-

ter". When the pressure increases more than 5 p.s.i.,

the filter should be cleaned. If the pressure does not

return to normal you must replace it. Make sure your

pressure gauge is kept in good working condition.

There are some after market filter element cleaning so-

lutions that will help remove oil and minerals that may

clog the filter. Oil and minerals can not be removed

with normal cleaning and back-washing. Spas are par-

ticularly susceptible to oil build up in the filter. Do not

acid wash a filter until you have removed all oil and

grease with a solution designed to remove such. Acid

washing a filter with oil in it will cause that oil to be-

come permanently embedded in the fibers. Cartridge

filter element replacement is suggested every 1 to 2

years. Sand filters should have the sand replaced every

3 to 5 years. D.E. type filter elements should be re-

moved and soaked in a solution at least every two years.

WATER FLOW

Proper water flow is critical to the heaters performance

and longevity. The maintenance of your filtering sys-

tem is directly related to the proper operation of the

heat pump. See pages 8 for other information regarding

filter cleaning and the start up procedures.

CIRCULATION PUMP

The circulation pump must be kept in good working

order to provide a steady rate of flow to the heater and

filtering system as a whole. The circulation pump must

be producing a flow rate in accordance with the manu-

facturers specifications within 10%. The pump should

run with a "full prime" without excessive restriction on

the vacuum and pressure side of the filtering system.

VACUUM & PRESSURE LEAKS

All vacuum and pressure leaks in the filtering system

must be eliminated immediately after occurring. Air

allowed into the filter system from the vacuum side of

the circulation pump will cause premature wear and

physical erosion to the heat exchanger and water pip-

ing inside the heater. Air turbulence will cause the wa-

ter pressure switch to malfunction.

Pressure leaks on the filtering system will allow the sys-

tem to lose vacuum and cause the water in the filter and

piping to back siphon or reverse flow through the sys-

tem when the circulation pump is off. Reverse flow

may cause the water pressure switch to malfunction.

CHLORINATORS

See chlorinator placement and chemical use guide-

lines.

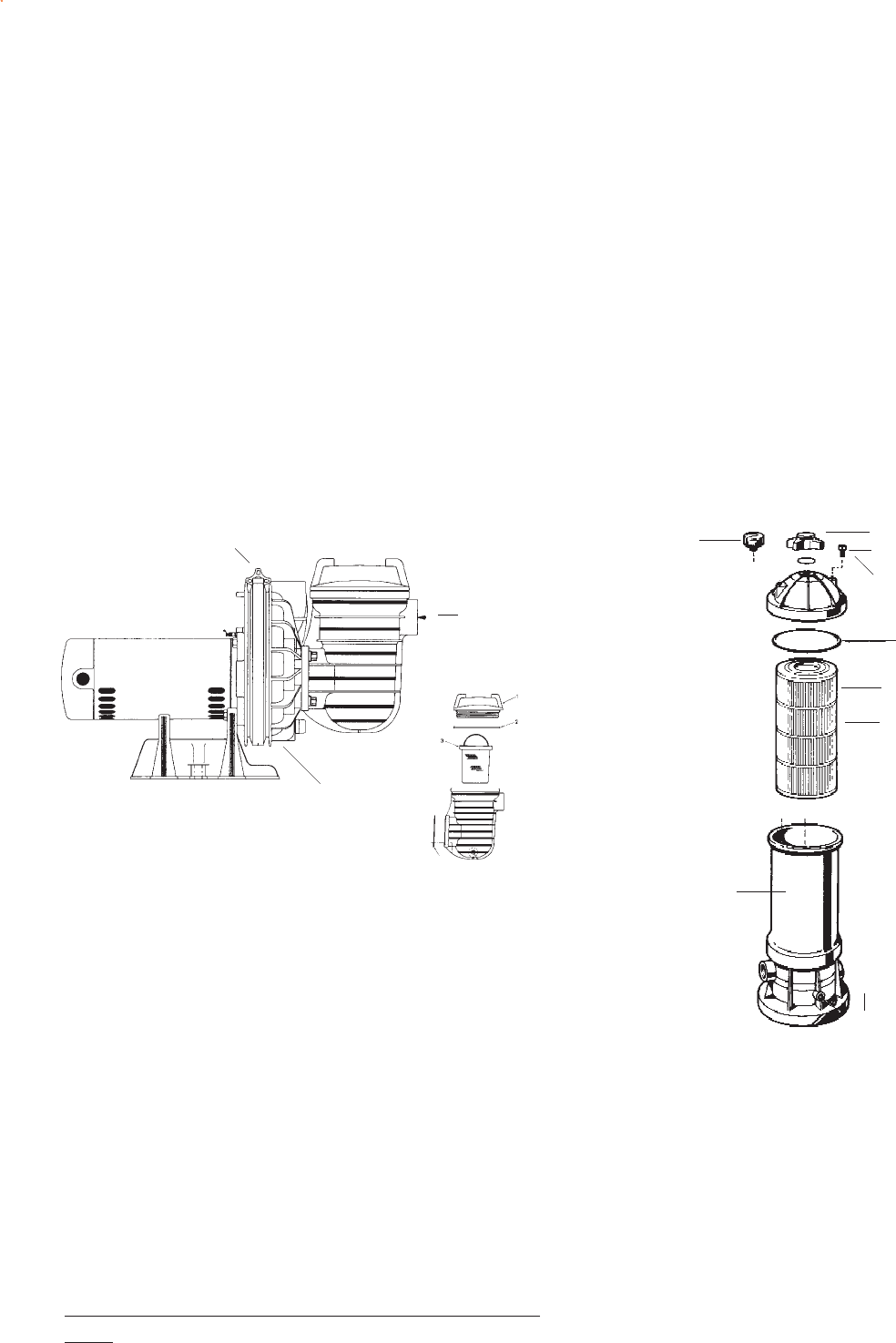

FILTER SYSTEM MAINTENANCE REQUIREMENTS

Air Bleed

Valve

PSI

Gauge

Locking Nut &

O-Ring

O-Ring

Element

Filter Tank

Typical

Cartridge

Filter

Inlet

Outlet

Pump Lid

"Suction"

Inlet

Electric

Motor

Lint Trap

Discharge Outlet

"Pressure"

Impeller

Housing

Typical Circulation Pump

16