234

EX-10

Operation mode switch

L: Light-ON

D: Dark-ON

Lights up when the output is

ON.

Operation indicator (Orange)

Switch

position

Description

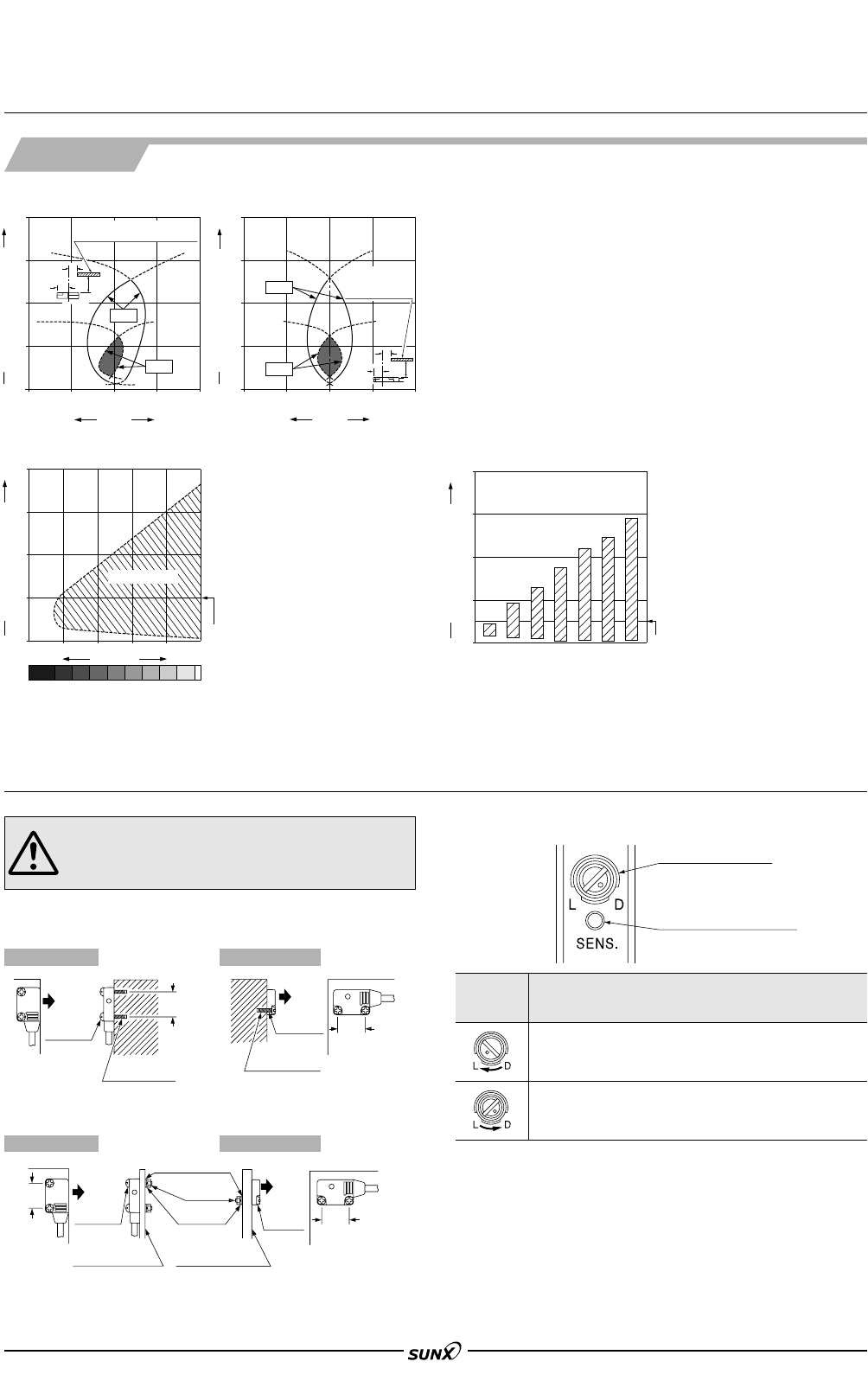

• Vertical (up and down) direction

SENSING CHARACTERISTICS (TYPICAL)

Convergent reflective type

Sensing fields

•

Horizontal (left and right) direction

Correlation between lightness and sensing range

Correlation between material (50ן50 mm 1.969ן1.969 in) and sensing range

5

0.197

10

0.394

05

0.197

10

0.394

0

10

0.394

20

0.787

30

1.181

40

1.575

White

N4

7 mm

0.276 in

#

L

Setting distance L (mm in)

Left

Right

Center

Operating point ?(mm in)

50ן50 mm 1.969ן1.969 in

Non-glossy paper

0

10

0.394

20

0.787

30

1.181

40

1.575

N2 N4 N6 N8

Lightness LightDark

N2N1 N3 N4 N5 N6 N7 N8 N9

Sensing range L (mm in)

Sensing region

Distance to

convergent point

0

20

0.787

10

0.394

40

1.575

60

2.362

80

3.150

Sensing range L (mm in)

Black circuit board

Black rubber sheet

IC tray (Black)

Glass epoxy printed circuit board

(Green masked surface)

Ceramic circuit board

White non-glossy paper

Stainless steel plate

Aluminum plate

(Hair line)

Aluminum-evaporated mirror

Distance to convergent point

EX-14Ⅺ

The sensing region is represent-

ed by oblique lines in the left

figure. However, the sensitivity

should be set with enough mar-

gin because of slight variation in

products.

Lightness shown on the left

may differ slightly from the

actual object condition.

The bars in the graph indicate the

sensing range for the respective

material. However, there is a

slight variation in the sensing

range depending on the product.

Further, if there is a reflective

object (conveyor, etc.) in the

background of the sensing object,

since it affects the sensing,

separate it by more than twice the

sensing range shown in the left

graph.

5

0.197

10

0.394

05

0.197

10

0.394

0

10

0.394

20

0.787

30

1.181

40

1.575

White

N4

#

7.75

mm

0.305 in

L

Setting distance L (mm in)

Down

Up

Center

Operating point ?(mm in)

50ן50 mm

1.969ן1.969 in

Non-glossy paper

()

The tightening torque should be 0.2 N⅐m or less.

Dark-ON mode is set when the switch is turned fully

counterclockwise (D side).

The tightening torque should be 0.2 N⅐m or less.

•

In case of using attached screws and nuts (Unit: mm in)

PRECAUTIONS FOR PROPER USE

This product is not a safety sensor. Its use is not

intended or designed to protect life and prevent body

injury or property damage from dangerous parts of

machinery. It is a normal object detection sensor.

Mounting

• In case of mounting on tapped holes (Unit: mm in)

Side sensing

Front sensing

Side sensing Front sensing

M2ן0.4 0.016 hole

tapped, 6 0.157 deep

Attached

screw

[M2 (length 10 0.394)]

11

0.433

Sensing

direction

Sensing

direction

M2ן0.4 0.016 hole

tapped, 7 0.276 deep

[M2 (length 8 0.315)]

Attached

screw

11

0.433

Thickness of

mounting plate: 2 0.079 or less

Attached

screw

[M2 (length 10 0.394)]

Thickness of

mounting plate: 2.5 0.098 or less

Spring

washers

Nuts

Flat washers

[M2 (length 8 0.315)]

Attached

screw

Sensing

direction

Sensing

direction

11

0.433

11

0.433

Operation mode switch (EX-15Ⅺ, EX-15EⅪ, EX-17Ⅺ and EX-17EⅪ only)

Light-ON mode is set when the switch is turned fully

clockwise (L side).

Others

• Do not use during the initial transient time (50ms)

(EX-15Ⅺ, EX-15EⅪ, EX-17Ⅺ, EX-17EⅪ: 100 ms) after

the power supply is switched on.

08/2005