Page 37 of 40

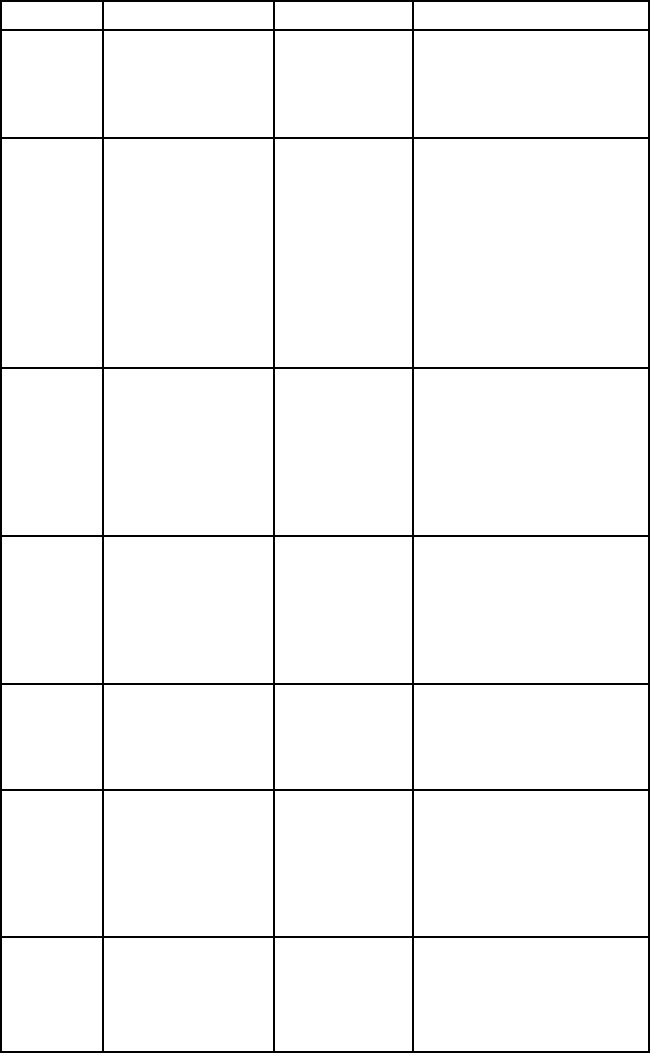

DISPLAY

No

display

lighted

FAILFAIL

FAILFAIL

FAIL

tESttESt

tESttESt

tESt

CHEC SP1CHEC SP1

CHEC SP1CHEC SP1

CHEC SP1

CHEC SP2CHEC SP2

CHEC SP2CHEC SP2

CHEC SP2

CHEC SPL1CHEC SPL1

CHEC SPL1CHEC SPL1

CHEC SPL1

CHEC SPH1CHEC SPH1

CHEC SPH1CHEC SPH1

CHEC SPH1

or

CHEC SPL2CHEC SPL2

CHEC SPL2CHEC SPL2

CHEC SPL2

CHEC SPH2CHEC SPH2

CHEC SPH2CHEC SPH2

CHEC SPH2

CHECCHEC

CHECCHEC

CHEC

LorELorE

LorELorE

LorE

SEnCSEnC

SEnCSEnC

SEnC

ArEAArEA

ArEAArEA

ArEA

(Alternates

with PV

when near)

MEANING

Display is blank. In-

strument is not get-

ting power, or the sup-

ply voltage is too low.

Fail test appears

upon power up if the

internal diagnostics

detect a failure. This

message may occur

during operation if a

failure is detected.

Displays flash.

This message will

appear upon power

up if SP1 is set out-

side of the SPL1/

SPH1 values or SP2

is set outside the

SPL2/SPH2 values.

This message ap-

pears at power up if

SPL or SPH values

are programmed out-

side the input range

ends.

This message ap-

pears if the Serial

Communications

has timed out.

Sensor Rate of

Change exceeded

the programmed lim-

its set for SEnC. Ap-

pears in display of

affected zone.

This message appears

if the ambiient temper-

ature of the control is

near or out of range or

RJC sensor is broken.

SP OUTPUTS

Set point

outputs inactive

Alarm inactive

Set point

outputs inactive

Alarm inactive

Set point

output(s)

inactive

Alarm active

Set point

output(s)

inactive

Alarm inactive

Set point

outputs active

Alarm inactive

Set point

output(s)

inactive.

Alarm Active

Set point

outputs active

Alarms active

ACTION REQUIRED

Check that the power supply is

on, or that the external fuses

are good.

The display alternates between

FAILtESt and one of the follow-

ing messages:

FACtFACt

FACtFACt

FACt

dFLtdFLt

dFLtdFLt

dFLt: Mem-

ory may be corrupted. Press the

ENTER key and the DOWN

ARROW key to start the factory

default procedure. Recheck con-

troller programming.

rEtrEt

rEtrEt

rEt

FACtFACt

FACtFACt

FACt:

Unrecoverable error, return to

factory for service.

Correct the

SP1SP1

SP1SP1

SP1,

SP2SP2

SP2SP2

SP2.or adjust

the

SPL1SPL1

SPL1SPL1

SPL1,

SPL2SPL2

SPL2SPL2

SPL2,

SPL2SPL2

SPL2SPL2

SPL2, or

SPH2SPH2

SPH2SPH2

SPH2

values by programming new

values.

Correct the

SPL1SPL1

SPL1SPL1

SPL1,

SPH1SPH1

SPH1SPH1

SPH1,

SPL2SPL2

SPL2SPL2

SPL2,

or

SPH2SPH2

SPH2SPH2

SPH2 values by program-

ming new values.

Restore the communications

line and switch the

LorELorE

LorELorE

LorE to

LOCLOC

LOCLOC

LOC.

Check for the cause of the er-

ror. The value setting may be

too slow for the process, or the

sensor is intermittent. Correct

the problem and press INDEX

and ENTER to reset.

Correct the ambient tempera-

ture conditions. Ventilate the

area of the cabinet or check for

clogged filters. If RJC broken,

return to factory for service.

DIAGNOSTIC ERROR MESSAGES