9

W415-0547 / B / 05.08.06

Use only Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp

or American Metal Amerivent venting components.

For Simpson Dura-Vent, Selkirk Direct Temp and American

Metal Amerivent, follow the installation procedure provided

with the venting components.

All outer pipe joints of these venting systems must be sealed

using Red RTV High Temperature Sealant.

Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp and

American Metal Amerivent venting systems must not be

combined.

A starter adaptor must be used and may be purchased from

the corresponding supplier:

PART SUPPLIER

Duravent - GDS924N Wolf Steel

Amerivent - 4DSCB-N1 American Metal

Direct Temp - 4DT-AAN Selkirk

For vent systems that provide seals on the inner exhaust fl ue,

only the outer air intake joints must be sealed using a red high

temperature silicone (RTV). This same sealant maybe used

on both the inner exhaust and outer intake vent pipe joints

of all other approved vent systems except for the exhaust

vent pipe connection to the fi replace fl ue collar which must

be sealed using the black high temperature sealant Mill Pac.

High temperature sealant must be ordered separately.

When using Wolf Steel venting components, use only the

following vent kits: WALL TERMINAL KIT GD175 (7-1/2'

of venting included), WALL TERMINAL KIT GD176 (24" of

venting included), or 1/12 TO 7/12 PITCH ROOF TERMINAL

KIT GD110, 8/12 TO 12/12 ROOF TERMINAL KIT GD111,

FLAT ROOF TERMINAL KIT GD112 or STOVE PERISCOPE

KIT GD180 (for wall penetration below grade) in conjunction

with the appropriate venting components.

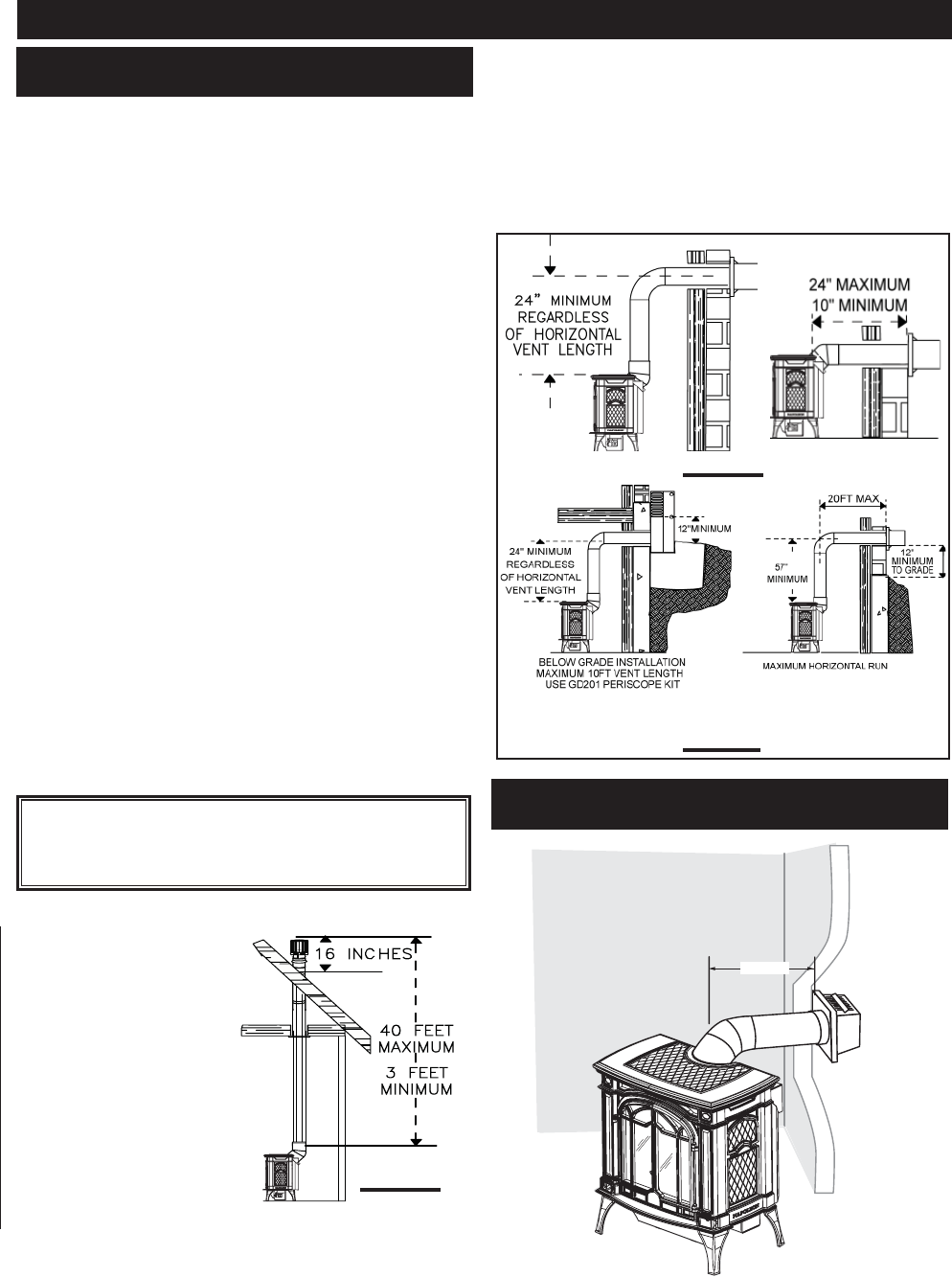

• These vent kits allow for

either horizontal or vertical

venting of the stove.

• The maximum number of

4" fl exible connections

is 3 horizontally or three

vertically (excluding the

stove and the air terminal

connections).

• When terminating

vertically, the minimum

vertical rise is 3 feet

above the stove and the

maximum vertical rise is

40 feet. FIGURE 4.

Deviation from the minimum vertical vent length can

create diffi culty in burner start-up and/or carboning.

Use an adjustable pipe as the fi nal length of rigid

piping to the stove for ease of installation.

FIGS 6a-b

FIGURE 5

HORIZONTAL RUN NOT TO

EXCEED VERTICAL RISE

• For optimum fl ame appearance and stove performance,

keep the vent length and number of elbows to a mini

mum.

• The air terminal must remain unobstructed at all times.

Examine the air terminal at least once a year to verify

that it is unobstructed and undamaged.

The maximum horizontal run with a 57 inch vertical rise im-

mediately above the stove is 20 feet . FIGURES 6a-b.

VENTING

VENTING LENGTHS &

AIR TERMINAL LOCATIONS

For optimum performance, it is recom-

mended that all horizontal runs have a

minimum ¼ inch rise per foot.

16 INCHES

3 FEET

MINIMUM

40 FEET

MAXIMUM

FIGURE 4

24” MAX

TYPICAL CORNER INSTALL

WITH ZERO RISE