23

W415-0547 / B / 05.08.06

NOTE: Check and adjust, if necessary, the primary air

to

7

/

16

” for propane and

1

/

4

” for natural gas. Replace the

screws.

7. Turn on the gas supply and check for gas leaks by brushing

on a soap and water solution.

Do not use open fl ame.

8. Replace the log set. Then light the pilot and main burner

to ensure that the gas lines have been purged.

9. Replace the glass viewing door and cast front. Turn on

the electrical supply to the fi replace.

Purge all gas lines with the glass door removed.

Assure that a continuous fl ow is at the burner before

re-installing the door.

1. Turn off the electrical

and gas supply to the fi re-

place.

2. Remove the cast front,

glass viewing door and

log set.

3. Remove the 2 securing

screws. Slide the burner

assembly to the right and

lift out.

4. Using a deep

9

/

16

” socket

wrench, remove the main

burner orifi ce. A

7

/

8

” back-up

wrench must be used on

the manifold, located below

the housing to ensure that

the aluminum tubing does

not twist or kink. Replace

the correct burner orifice

using pipe thread compound.

5. Loosen nut and replace with appro-

priate injector

6. Reinstall the burner ensuring that the

Venturi tube fi ts over the orifi ce.

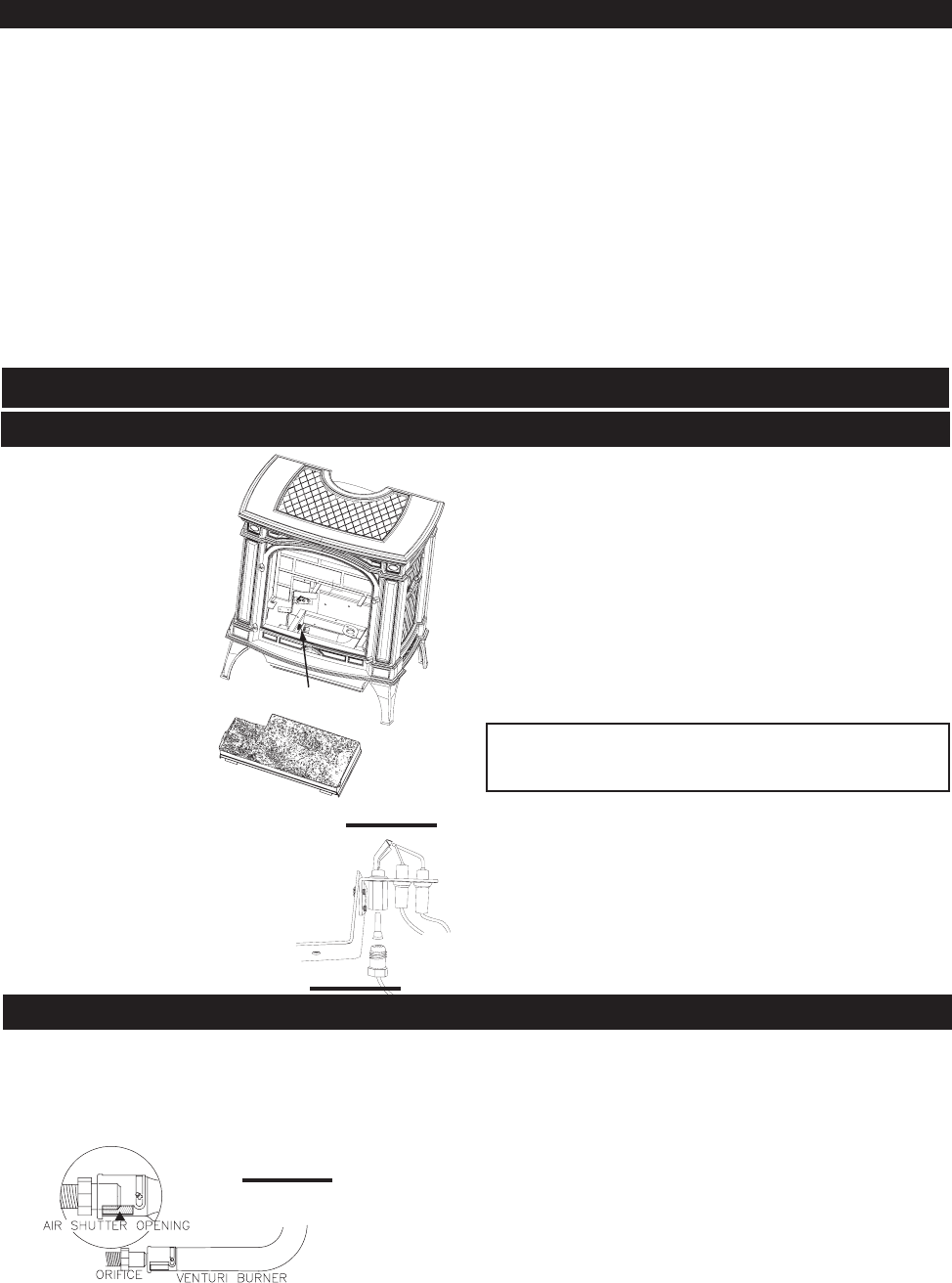

ORIFICE

LOCATION

BURNER

ASSEMBLY

FIGURE 37

Air shutter adjustment must only be done by a

qualifi ed gas installer!

FIGURE 36

ADJUSTMENTS

PILOT INJECTOR AND ORIFICE REPLACEMENT

VENTURI ADJUSTMENT

TURN OFF THE GAS AND UNPLUG

ELECTRICAL POWER BEFORE

SERVICING THE STOVE!

CAUTION: Label all wires prior to disconnection when servic-

ing controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing. This stove

and its venting system should be inspected before use and

at least annually by a qualifi ed service person. The fi replace

area must be kept clear and free of combustible materials,

gasoline or other fl ammable vapours and liquids. The fl ow of

combustion and ventilation air must not be obstructed.

1. In order to properly clean the burner and pilot assembly,

remove the logs exposing both assemblies.

2. Keep the control compartment, logs, burner, air shutter

opening and the area surrounding the logs clean by vacuum-

ing or brushing, at least once a year.

3. Check to see that all burner ports are burning. Clean out

any of the ports which may not be burning or are not burning

properly.

4. Check to see that the pilot fl ames are large enough to

engulf the thermocouple and the thermopile on one leg and

reaches toward the burner on the other leg.

5. Replace the cleaned logs.

6. Check to see that the main burner ignites completely on

all openings when the gas knob for the burner is turned on.

A 5-10 second total light-up period is satisfactory. If ignition

takes longer, consult your Napoleon dealer/distributor.

7. Check that the door gasketing is not broken or missing.

MAINTENANCE

Remove the 2 screws securing the burner. Natural gas models

have air shutters set to 0.25" open (1/4"). Propane models

have air shutters set to 0.438" open (7/16").

After making adjustments replace the burner ensuring that the

venturi tube fi ts over the orifi ce and replace the screws.

Closing the air shutter will cause a more yellow flame,

but can lead to carboning. The flame may not appear

yellow immediately; allow 15 to 30 minutes for the final

flame colour to be established.

FIGURE 35

This must be carried out by an AUTHORIZED

REPRESENTATIVE OF WOLF STEEL LTD. or a QUALIFIED

GAS INSTALLER in accordance with local codes or in the

absence of local codes with the requirements of the provin-

cial / state authorities having jurisdiction and in accordance

with the requirements of the CAN1-B149 Installation Code in

Canada and the ANSI Z223.1 National Fuel Gas Code in the

United States.