19

W415-0210 / E / 06.25.03

Before attaching elbows to the collars on the back

of the fireplace, 1½" will need to be trimmed off

the 4" collar.

REAR VENT APPLICATION: Attach 4" and 7" elbows to

the fireplace. Secure with 3 screws and seal the joints and

screw heads using high temperature sealant. Proceed to

step 1 below.

TOP VENT APPLICATION:

1. Move the fireplace into position.

2. Fasten the roof support to the roof using the screws

provided. FIGURE 30. The roof support is optional. In this

case the venting is to be adequately supported using ei-

ther an alternate method suitable to the authority having

jurisdiction or the optional roof support.

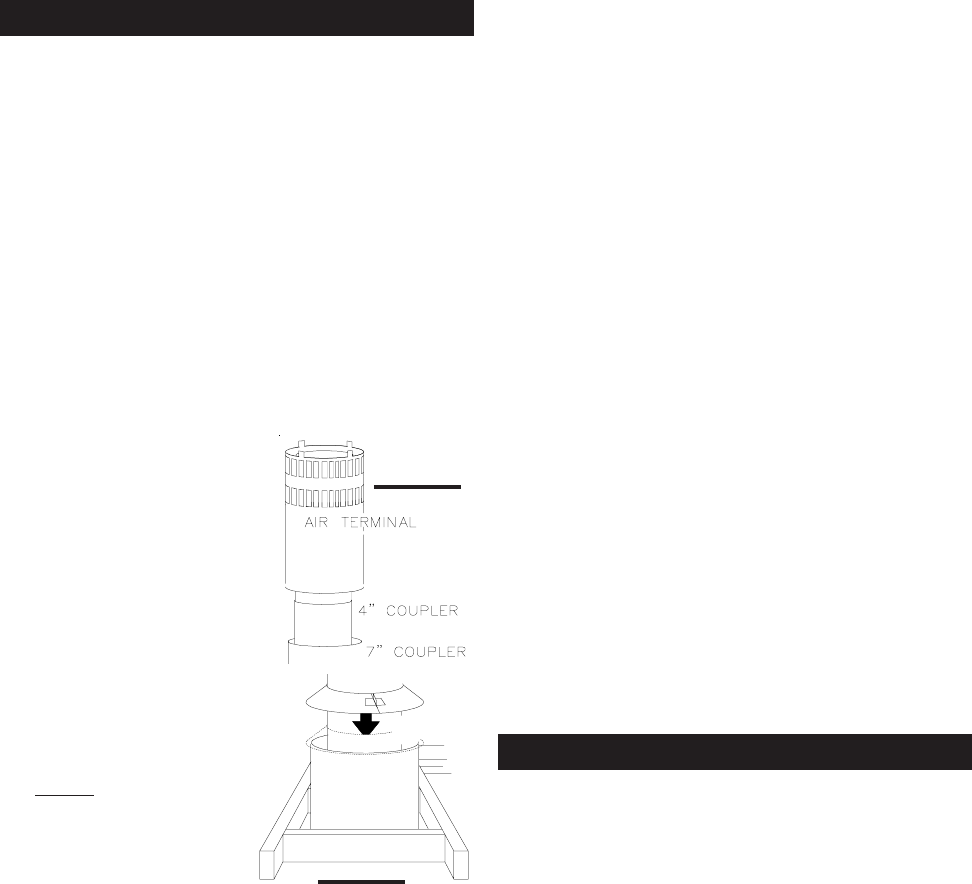

3. Apply high temperature sealant to the outer edge of the

inner sleeve of the air terminal. Slip a 4" diameter coupler a

minimum of 2" over the sleeve and secure using 3 screws.

4. Apply high temperature seal-

ant to the outer edge of the of the

outside sleeve of the air terminal.

Slip a 7" diameter coupler over the

sleeve and secure as before. Trim

the 7" coupler even with the 4" cou-

pler end.

5. Thread the air terminal pipe

assembly down through the roof

support and attach, ensuring that

a minimum 16" of air terminal will

penetrate the roof when fastened.

If the attic space is tight, we rec-

ommend threading the Wolf

Steel vent pipe collar or equiva-

lent

loosely onto the air terminal

assembly as it is passed through

the attic. The air terminal must be

located vertically and plumb.

VENT PIPE

SHIELD

VEN

T

PIP

E

COLLA

R

FIGURE 36

FIGURE 35

6. Remove nails from the shingles, above and to the

sides of the chimney. Place the flashing over the air termi-

nal and slide it underneath the sides and upper edge of

the shingles. Ensure that the air terminal is properly

centered within the flashing, giving a 3/4" margin all around.

Fasten to the roof. Do NOT nail through the lower portion of

the flashing. Make weather-tight by sealing with caulking.

Where possible, cover the sides and top edges of the flash-

ing with roofing material.

7. Apply a heavy bead of waterproof caulking 2 inches

above the flashing. Slide the storm collar around the air

terminal and down to the caulking. Tighten to ensure that a

weather-tight seal between the air terminal and the collar

is achieved. Attach the other storm collar centered between

the air intake and air exhaust slots onto the air terminal.

Tighten securely. Attach the rain cap.

8. Continue adding rigid venting sections, sealing and

securing as above. Attach a 4" collapsed telescopic pipe

to the last section of rigid piping. Secure with screws and

seal. Repeat using a 7" telescopic pipe.

9. REAR VENT APPLICATION: Run a bead of high tem-

perature sealant around the outside of the 4" elbow. Pull

the adjustable pipe a minimum 2" onto the elbow. Secure

with 3 screws. Repeat with the 7" telescopic pipe.

TOP VENT APPLICATION: Run a bead of high tempera-

ture sealant around the outside of the 4" collar on the fire-

place. Pull the adjustable pipe a minimum of 2" onto the

collar. Secure with 3 screws. Repeat with the 7" telescopic

pipe.

10. In the attic, slide the vent pipe collar down to cover up

the open end of the shield and tighten. This will prevent

any materials, such as insulation, from filling up the 1" air

space around the pipe.

Model GD36NTR Vertical Terminal only:

Vertical terminations running longer than 15 feet may dis-

play a very active flame. If this appearance is not desirable,

the vent exit must be restricted using restrictor plate kit,

RP-KT. This reduces the velocity of the exhaust gases,

slowing down the flame pattern and creating a more tradi-

tional appearance. Specific instructions are included with

the kit.

RESTRICTING VERTICAL VENTS

VERTICAL VENTING INSTALLATION