9

7. Electrical work

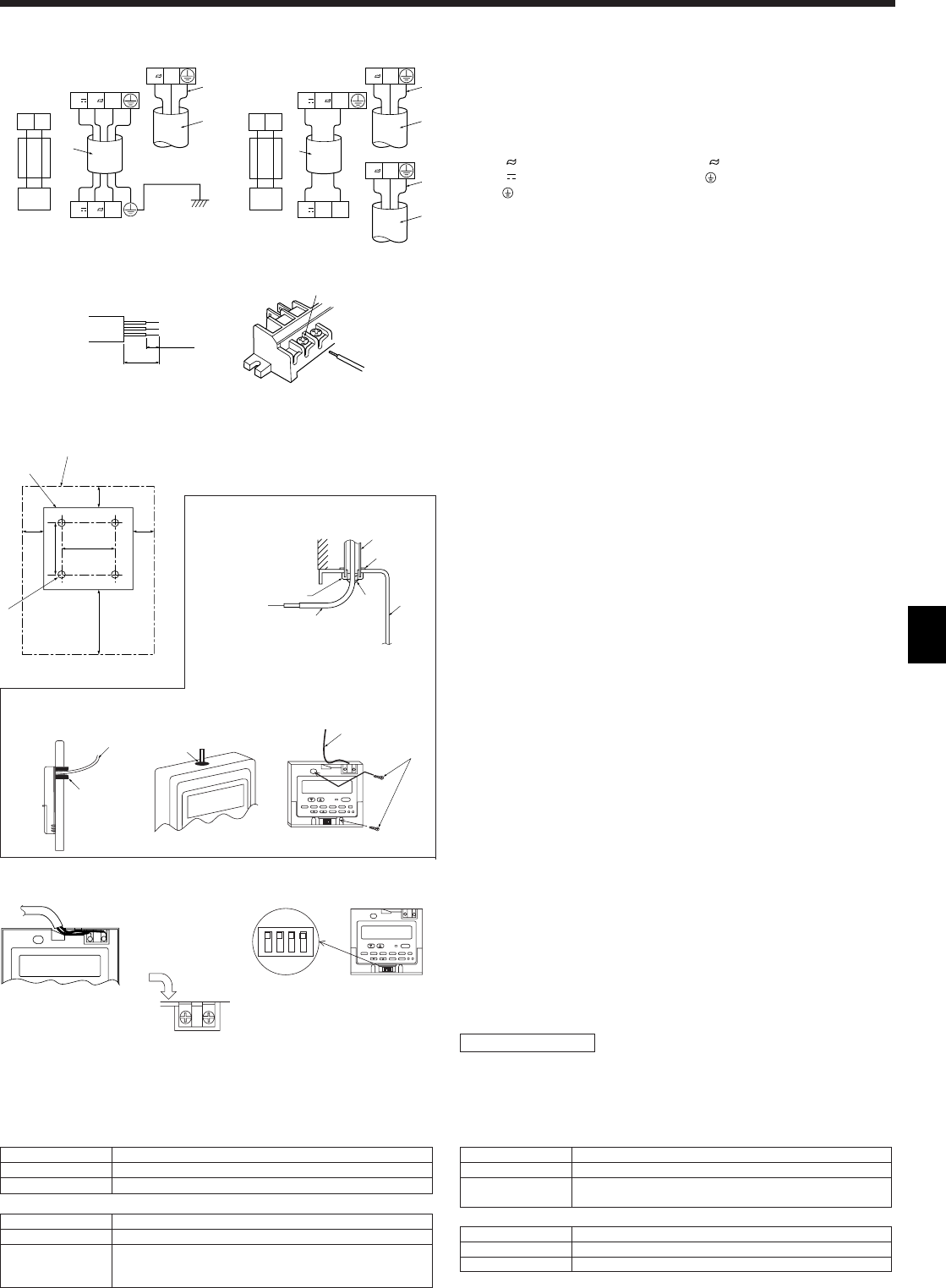

Fig. 7-4

LN

N

2 3

N

2 3

1

2

5

12

7

6

3

4

65 mm

15 mm

1

2

Fig. 7-3

• Perform wiring as shown in the diagram to the lower left. (Procure the cable lo-

cally). (Fig. 7-3)

Make sure to use cables of the correct polarity only.

1 Connecting cable 2 Power supply cable

4 core VVF cable 3 core with ground IEC cord

• SEZ-A12:1.0 mm

2

or more • SEZ-A12:1.0 mm

2

or more

• SEZ-A18, A24:1.5 mm

2

or more • SEZ-A18, A24:1.5 mm

2

or more

Colors Colors

N : Blue N : Blue

2 : Brown L : Brown

3 : Red : Green/Yellow

: Green/Yellow

3 Indoor

4 Outdoor

5 Always install an earth longer than other cables

6 Remote controller cable

Wire No × size (mm

2

) : Cable 2C × 0.69

This wire accessory of remote controller

(wire length : 10m, non-polar)

7 Remote controller

• Connect the terminal blocks as shown in the diagram below. (Fig. 7-4)

1 Loosen terminal screw

2 Terminal bed

(1) Use care not to make mis-wiring.

(2) Firmly tighten the terminal screws to prevent then from loosening.

(3) After tightening, pull the wires lightly to confirm that they do not move.

7.3. Remote controller

7.3.1. For wired remote controller

1) Installing procedures

(1) Select an installing position for the remote controller. (Fig. 7-5)

The temperature sensors are located on both remote controller and indoor unit.

s Procure the following parts locally:

Two piece switch box

Thin copper conduit tube

Lock nuts and bushings

A Remote controller profile

B Required clearances surrounding the remote controller

C Installation pitch

(2) Seal the service entrance for the remote controller cord with putty to prevent

possible invasion of dew drops, water, cockroaches or worms. (Fig. 7-6)

A For installation in the switch box:

B For direct installation on the wall select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run

the remote controller cord from the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cut-

out notch with putty similarly as above.

B-1. To lead the remote controller cord from the back of the controller:

B-2. To run the remote controller cord through the upper portion:

(3) For direct installation on the wall

C Wall

D Conduit

E Lock nut

F Bushing

G Switch box

H Remote controller cord

I Seal with putty

J Wood screw

2) Connecting procedures (Fig. 7-7)

1 Connect the remote controller cord to the terminal block.

A To the terminal block on the indoor unit

B TB6 (No polarity)

2 Set the dip switch No.1 shown below when using two remote controller’s for the

same group.

C Dip switches

Setting the dip switches

The dip switches are at the bottom of the remote controller. Remote controller Main/

Sub and other function settings are performed using these switches. Ordinarily, only

change the Main/Sub setting of SW No.1. (The factory settings are all “ON”.)

30

46

30

30120

83.5

A

B

C

F

A

H

C

D

E

G

I

I

I

H

B

J

H

B-1. B-2.

Fig. 7-6

A

AB TB6

B

1

234

ON

1

234

ON

C

<SW No. 1>

SW contents Main Remote controller Main/Sub setting

ON/OFF

Comment Set one of the two remote controllers at one group to “Main”

Main/Sub

<SW No. 2>

SW contents Main When remote controller power turned on

ON/OFF

Comment

When you want to return to the timer mode when the power is restored

after a power failure when a Program timer is connected, select “Timer

mode”.

Normally on/Timer mode on

<SW No. 3>

SW contents Main Cooling/heating display in AUTO mode

ON/OFF

Comment

When you do not want to display “Cooling” and “Heating” in the Auto

mode, set to “No”.

Yes/No

<SW No. 4>

SW contents Main Intake temperature display

ON/OFF

Comment When you do not want to display the intake temperature, set to “No”.

Yes/No

Fig. 7-5

Fig. 7-7

LN

N

3

N

2 3

1

2

5

LN

2

5

12

7

6

3

4

(1) SEZ-A12AR (1:1 SYSTEM) (2) SEZ-A18/24AR (1:1 SYSTEM) OR

MULTI SYSTEM