Schrader valve

Front panel

V

apor Connection

Cut here after

relieving pressure

5

Always use proper refrigerant line sizes as shown:

Unit size

P12, P18 1/4” liquid x 1/2” gas

P24 – P54 3/8” liquid x 5/8” gas

Both refrigerant lines need to be insulated all the way up to the

cabinet. Make sure the openings in the cabinet around the refrigerant

lines are sealed. 3/8 in thick insulation is the minimum recommended

thickness. Based on ambient conditions, local codes and line length,

thicker insulation may be desired.

Drain Connections

IMPORTANT!

Over-tightening the drain connections could result in drain pan

breakage and failure.

The air handler contains three sets of ¾” FPT drain connections.

When the unit is used in the vertical position, there are a left-hand set

and a right-hand set. When the unit is mounted horizontal (left only)

there is one set. Each set contains a primary drain and a secondary

or auxiliary drain. The primary drain is the one that is lowest (even

with the bottom of the pan). The secondary drain is at the higher level.

These units operate with a negative pressure at the drain

connections and require a drain trap be installed to prevent air from

being drawn in and preventing positive drainage.

The trap needs to be installed as close to the unit as possible. Make

sure the top of the trap is below the connection to the drain pan to

allow complete drainage of the pan.

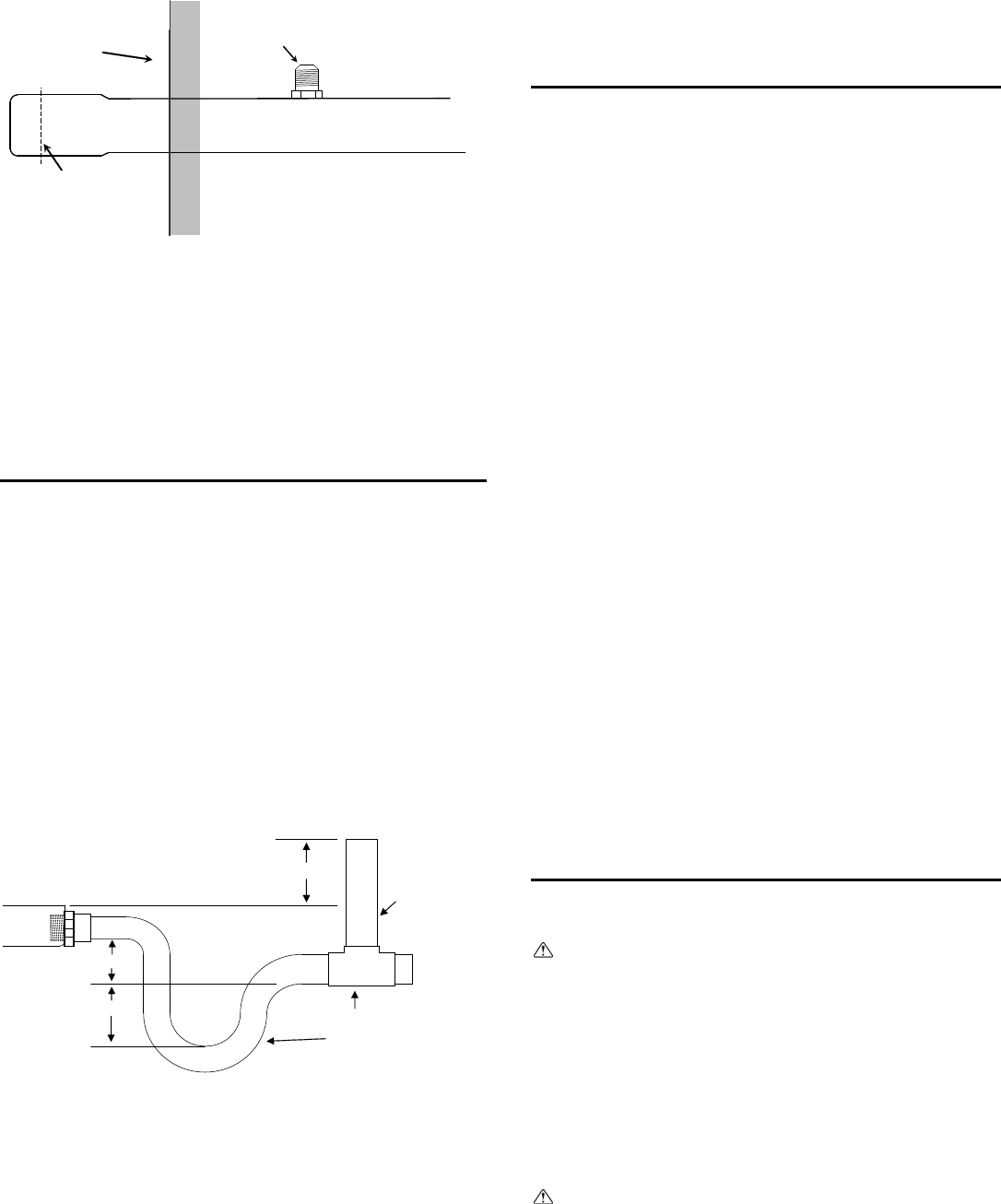

2" Min.

Anti-syphon

air vent

2" Min.

2" Min.

Vent T

Drain Trap

Note: Horizontal runs must also have an anti-siphon air vent

(standpipe) install ahead of the horizontal run to eliminate air trapping.

Horizontal drain lines must be pitched a minimum 1/8” per foot.

Route the drain lines outside or to an appropriate drain. Drain lines

must be installed so they do not block service access to the front of

the unit. 24” clearance in the front is for routine maintenance or

service.

Note: Check local codes before connecting the drain line to an

existing drainage system.

Insulate the drain lines where sweating could cause water damage.

Upon completion of installation, it is the responsibility of the

installer to ensure the drain pan(s) is capturing all condensate, and

all condensate is draining properly and not getting into the

ductwork/system.

Vertical Mounting:

When mounted vertically, the air handler has a choice of left or

right hand drain connections. Select the drain connection set that

is most convenient for routing piping.

For left hand drains the connections are visible and ready for

installation. Attach the drain connectors finger tight and install the

drain line. For right hand remove the caps covering the drain pan

openings. Remove the plugs and reinstall in the left hand drain

opening. Install cover caps over these plugs. Now attach the drain

connector finger tight and install the drain line.

IMPORTANT!

Over-tightening the drain connection could result in drain pan

breakage and failure.

The secondary connection if used should be connected to a

separate drainage system. Run the secondary drain so the

occupants will be able to notice water flowing through the

secondary drain indicating a blockage in the primary drain.

Optional use for the secondary is a primary drain line overflow

switch (provided by others). This device will shut the cooling

operation unit down in the event of a primary drain line blockage.

See wiring section for connecting this device.

Horizontal:

If the unit is installed horizontally, remove the plugs installed in the

drain pan openings and attach connector finger tight and route

drain line. Any vertical drain pan openings must be covered to

eliminate air loss.

IMPORTANT!

Over-tightening the drain connection could result in drain pan

breakage and failure.

The secondary connection if used should be connected to a

separate drainage system. Run the secondary drain so the

occupants will be able to notice water flowing through the

secondary drain indicating a blockage in the primary drain.

Optional use for the secondary is a primary drain line overflow

switch (provided by others). This device will shut the cooling

operation unit down in the event of a primary drain line blockage.

See wiring section for connecting this device.

ELECTRICAL WIRING

Warning:

Electrical work should be done by a qualified electrical

contractor in accordance with “Engineering Standards for

Electrical Installation” and supplied installation manuals.

If the power circuit lacks capacity or has an installation

failure, it may cause a risk of electrical shock or fire.

− Be sure to follow local and national code requirements

when wiring these units

− Install the unit to prevent that any of the control circuit

cables (remote controller, transmission cables) is brought

in direct contact with the power cable outside the unit.

− Ensure that there is no tension on any wire connections

Caution:

Be sure to ground the unit. Do not connect the grounding

cable to any gas pipe, water pipe, lightening rod, or

telephone earth cable. Incomplete grounding may cause a

risk of electrical shock.