Installation Clearances

TOP View

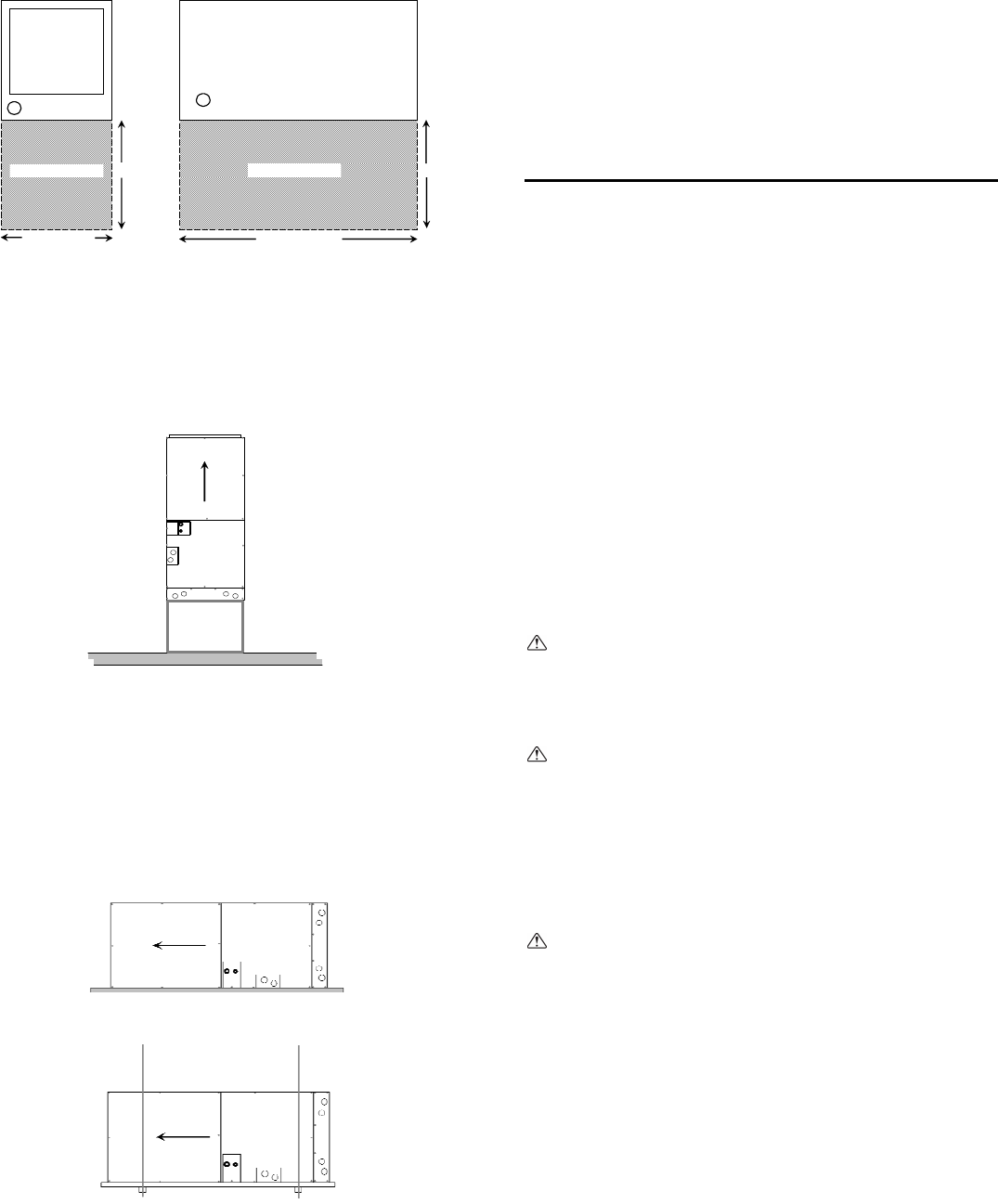

Horizontal Installation

24"24"

Width of Unit

TOP View

Vertical Installation

Length of Unit

Clearance AreaClearance Area

4

Vertical Applications: The air handler must be supported on the

bottom only and set on a solid floor with a return plenum below or

field supplied supporting frame or plenum. Securely attach the air

handler to the floor or supporting frame or plenum.

Horizontal (LEFT ONLY) Installations: No changes need to

be made to the unit for horizontal installation. The unit can be

installed on a platform or suspended from rails as shown below. The

rails must run the length of the unit and be of sufficient strength to

support the weight of the unit and connected ductwork. Vibration

isolation is recommended for horizontal installations. Some

jurisdictions may require an auxiliary drain pan be mounted under the

unit. Always follow local or national code requirements.

_____________________________________

Air Filter

An air filter (provided by others) is to be installed on the return side

of the air handler. The face area and pressure drop is to be

determined by the installing contractor based on the overall static

pressure performance of the system including supply and return

ductwork sizing. The factory static pressure performance is .30”

esp. A field selectable .50 esp. is available. See instructions for

changing to .50 esp in the electrical section.

REFRIGERANT PIPING

This piping work must be done in accordance with the installation

manuals for both outdoor unit and BC controller (R2/WR2 series)

Series R2 is designed to operate in a system that the refrigerant

pipe from an outdoor unit is received by the BC controller and

branches at the BC controller to the indoor units.

For constraints on piping length and allowable difference of

elevation, refer to the design section of the engineering manual.

Unit Mounted on Return Plenum

The method of pipe connection on the air handler is braze

connection.

Cautions of refrigerant piping

Be sure to use non-oxidative procedures for

brazing to ensure that no foreign matter or

moisture enters the piping.

ALWAYS USE A NITROGEN PURGE IN THE PIPING

DURING BRAZING

Provide proper bracing for refrigerant piping so no load is

imparted upon the connections at the air handler.

Warning:

When installing and moving the unit, do not charge it with

refrigerant other than the refrigerant specified on the unit.

Mixing of a different refrigerant, air, etc. may cause the

refrigerant cycle to malfunction and result in severe

damage.

Caution:

Use refrigerant piping made of C1220 (Cu-DHP)

phosphorous deoxidized copper as specified in ASTM

B280 Standard for copper and copper alloy seamless

pipes and tubes. In addition, be sure that the inner and

outer surfaces of the pipes are clean and free of

hazardous sulphur, oxides, dust/dirt, shaving particles,

oils, moisture, or any other contaminant.

Never use existing refrigerant piping.

Platform Mounting

Caution: COIL UNDER PRESSURE

Always wear safety glasses when working around

pressurized devices.

The air handlers are shipped with a nitrogen holding

charge in the coil. Carefully follow these instructions when

releasing the charge.

Suspended Mounting

The suction line stub contains a schrader valve where the factory

pre-charged the coil with nitrogen. This valve is located behind the

panel where the suction line comes out. This can be accessed by

removing the blower panel (top panel). (See drawing below)

Remove the cap and depress the schrader valve core to release

all pressure within the coil. Replace the cap and finger tighten.

Once all pressure is released the brazed ends of both tubes can

now be removed with a tubing cutter. If necessary ream the

connections to accept the refrigerant lines.