CLEAN-OUT PANEL

Remove clean-out panel on a regular basis to clean out

accumulation of foreign materialbuild-up. Keep this area

clean for proper cross conveyor chain operation.

CROSS CONVEYOR CHAIN

WITH CROSS APRON HOLD DOWNS

Correct adjustment of the cross apron chain occurs

when 12" of chain, APRON SLAT does not touch the

BOTTOM PAN of the cross apron return area at the dis

-

charge opening. To tighten the chain, loosen the two

bolts securing the slotted bearing bracket at each side of

the discharge opening. Tighten the chain by tightening

the nut on the adjuster bolt. Adjust both sides equally.

Retighten the bearing bracket bolts.

MAIN APRON CHAINS

After unloading the first ten loads from the front and also af-

ter unloading the first ten loads from the rear check the main

apron chain tension. After initial adjustment check chain

tension daily for the next five days of operation. Initial wear

in of chain will require adjustment to maintain proper chain

tension. FAILURE TO MAINTAIN PROPER CHAIN TEN-

SION MAY VOID WARRANTY. Removable master links

are included in each of the four strands for tightening after

tightener travel is at its maximum. Remove a link from each

of the fourstrands at the sametime to assure proper timing.

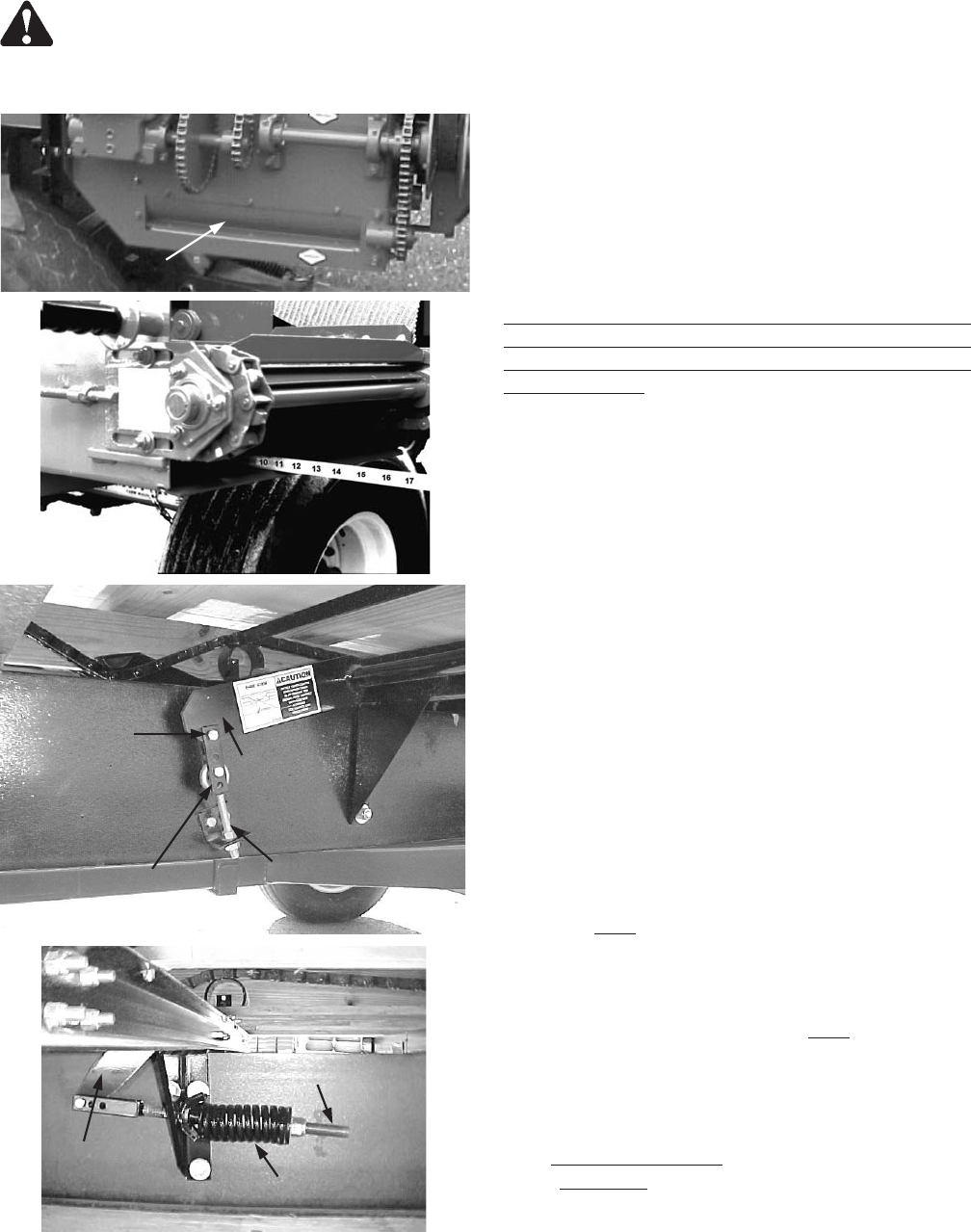

The main aprons are each independently tensioned by

an anchoring, adjustable bolt and pivoting arm tightener

system.

PRIOR TO 08 SERIAL NUMBERS-To tighten the main

aprons, tighten down the anchoring eye bolts centrally

located at each

side of the forage box on the steel 10”

stringers.

08 SERIAL NUMBERS AND LATER-To tighten the

main aprons, tighten the tensioner rod on the spring

loaded tensioner centrally located at each

side of the for

-

age box on the steel 10” stringers. Tighten the spring to

a 5” compressed length.

In addition to tightening the anchoring eye bolts, there is

located on the inner chain strands of each apron assem

-

bly a fine adjustment bolt

on the pivoting arm tightener.

Adjust as needed

to equalize stretch in chain strand pairs

of each independent apron assembly. See page 26.

3200 & 4200 Series -- 25 –

ADJUSTMENT DIAGRAMS (Shields Removed for Illustration Purposes Only)

ADJUSTMENTS

WARNING: DISCONNECT PTO DRIVE SHAFT (OR HYDRAULIC POWER SOURCE) BEFORE

CLEANING, ADJUSTING, LUBRICATING OR SERVICINGTHIS MACHINE. FAILURE TO HEED MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

PIVOT ARM

PIVOT BOLT

SHACKLE BRACKET

ANCHORING EYEBOLT

PRIOR TO 08 SERIAL #’S

CLEAN OUT PANEL

PIVOT ARM

TENSIONER ROD

SPRING

08 SERIAL #’S & LATER