Slow up, but do not stop the VARIABLE SPEED control

when shifting to “HI” RANGE.

CAUTION: YOU CAN MOVE THE RANGE CON

-

TROL LEVER TO “HI” FOR CLEAN-OUT AT THE END

OF UNLOADING AND YOU MAYALSO FIND IT TO BE

AN APPROPRIATE SPEED SELECTION FOR SMALL

OR PARTIAL LOADS.

DO NOT STARTAND UNLOAD

FULL LOADS IN “HI” RANGE.

NOTE: Control lever settings must be made while the

forage box front unloading unit is in operation. Moving

the control levers with the unloading unit stopped will be

difficult or impossible. This may cause equipment dam

-

ages and may void the manufacturer’s warranty.

When finished unloading the forage box, perform the

“Shut Down Procedures.”

SHUTDOWN PROCEDURES

For proper operation, it is IMPORTANT that when un

-

loading is completed to slowly

return the VARIABLE

SPEED control lever to the “Neutral” position and then

the HI-LO RANGE control lever to the “Neutral” position.

Then, disengage the INDEPENDENT OUTFEED

CLUTCH control lever to the “Stop” position. This will

prepare the forage box front unloading unit for proper

“start-up” on the next load of forage.

NOTE: Control lever settings must be made while the

forage box front unloading unit is in operation. Moving

the control levers with the unloading unit stopped will be

difficult or impossible. This may cause equipment dam

-

ages and may void the manufacturers warranty.

Idle down the tractor engine rpms. Disengage the PTO

drive shaft and turn the tractor “OFF.” When all move

-

ment has stopped, disconnect the PTO drive shaft from

the forage box unloading tractor and return it to the PTO

storage bracket. Secure the PTO drive shaft into the

PTO storage bracket with the rubber tie down strap.

Shut down the silo filling blower tractor and wait for all

motion to stop. If the forage box is equipped with a cross

conveyor extension, raise it up to the transport position

and securely latch if before traveling on roadways.

The unloading process described is to be performed by

the operator alone. This will eliminate unexpected

“start-ups” and minimize other hazards that could result

by more that one person in control. If the forage box or

silo filling blower should become clogged, shut off all

power to the forage box and blower. Wait for all motion

to stop. Disconnect PTO drive shaft or hydraulic supply

and return hoses. Then, clean out the machine.

Never use “live” power to aid in the clean-out of a

clogged machine. If any mechanism fails, move the for

-

age box to a safe work area and then repair the mecha

-

nism before proceeding with unloading of the forage. If

repairs require the removal of forage from inside of the

forage box, then removethe reardischarge door (bolted

hinges on top of each side) and then empty the forage

manually by hand through the rear opening.

DANGER: NEVER ENTER THE FORAGE BOX

OR FRONT UNLOADING UNIT FOR ANY REASON

WITHOUT FIRST DISCONNECTING PTO DRIVE

SHAFT OR HYDRAULIC HOSES FROM POWER

SUPPLY. FAILURE TO HEED MAY RESULT IN SERI

-

OUS PERSONAL INJURY OR DEATH.

Never enter the forage box for any reason if there is any

possibility of power being applied to the unit.

3200 & 4200 Series -- 17 –

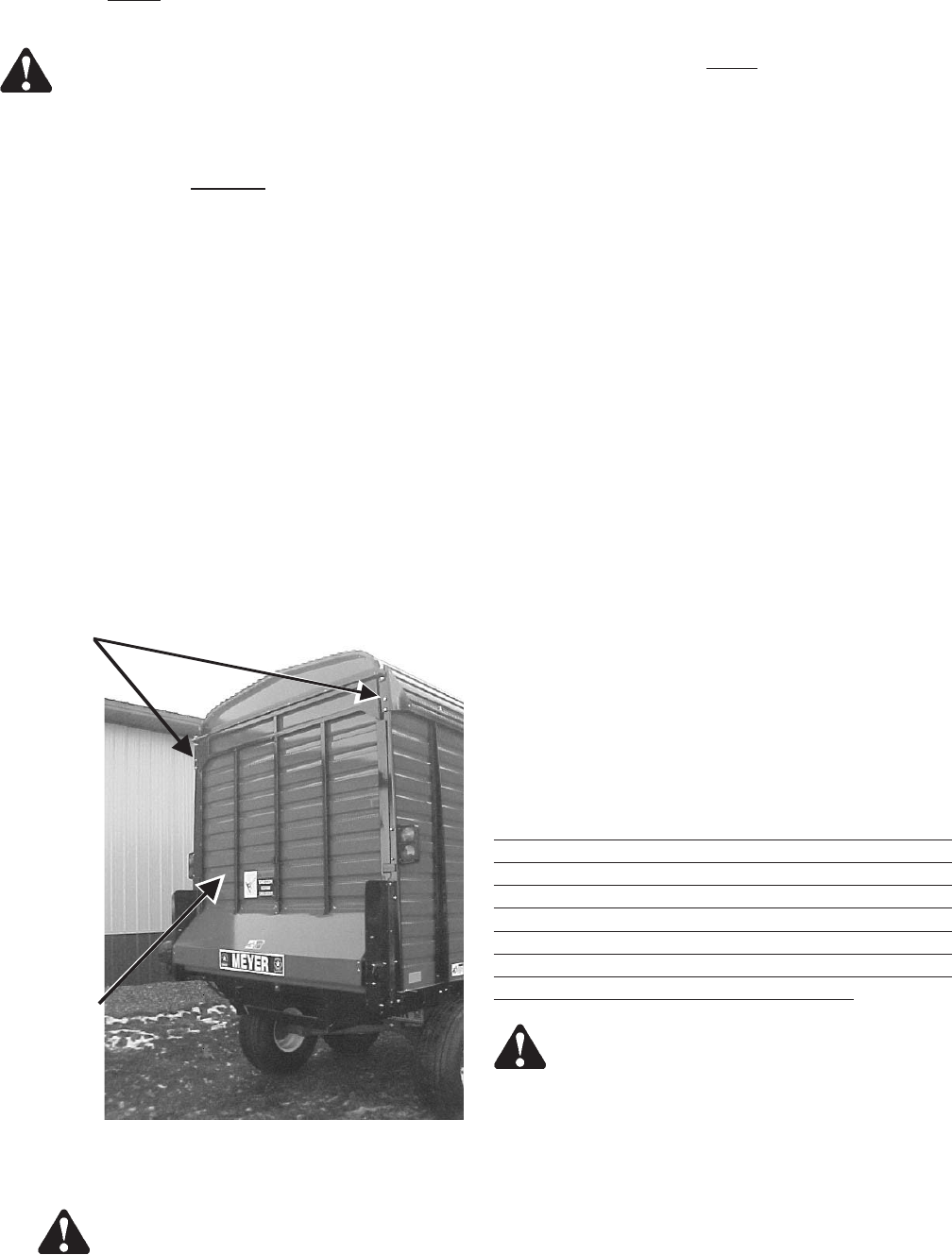

REAR OPENING DISCHARGE DOOR

CAUTION (QUICK RELEASE!)

HINGE

BOLTS

REAR

DISCHARGE

DOOR