58

32. Rate of flue product movement is controlled by

“V” Baffles on the heat exchanger to maximize

heat transfer.

33. Heated products of combustion then pass over the

Secondary Heat Exchanger to absorb additional heat.

34. Flue products pass into the flue collector and

are exhausted from the unit.

End of Sequence

35. Set Point temperature is satisfied.

36. Power to the gas valves is turned off.

37. Combustion Air Blower ramps up to 100% speed

and runs for a 30 second post purge timing and

turns off.

38. Excel 10 is now in a standby mode waiting for the next

“Call for Heat”.

MAINTENANCE

Listed below are items that must be checked to ensure safe reliable

oper a tions. Verify proper operation after servicing.

CAUTIONƽ

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation.

A. EXAMINE THE VENTING SYSTEM at least once a year.

Check more often in the first year to determine inspection

interval. Check all joints and pipe connections for tightness,

corrosion or deterioration. Flush the condensate drain hose

with water to clean. Clean screens in the venting air intake

system as re quired. Have the entire system, in clud ing the

venting system, pe ri od i cal ly inspected by a qualified service

agency.

B. VISUALLY CHECK MAIN BURNER FLAMES at each

start up after long shutdown pe ri ods or at least every six

months. A burner viewport is located on the burn er mounting

flange.

WARNINGƽ

The area around the burner viewport is hot and direct

contact could result in burns.

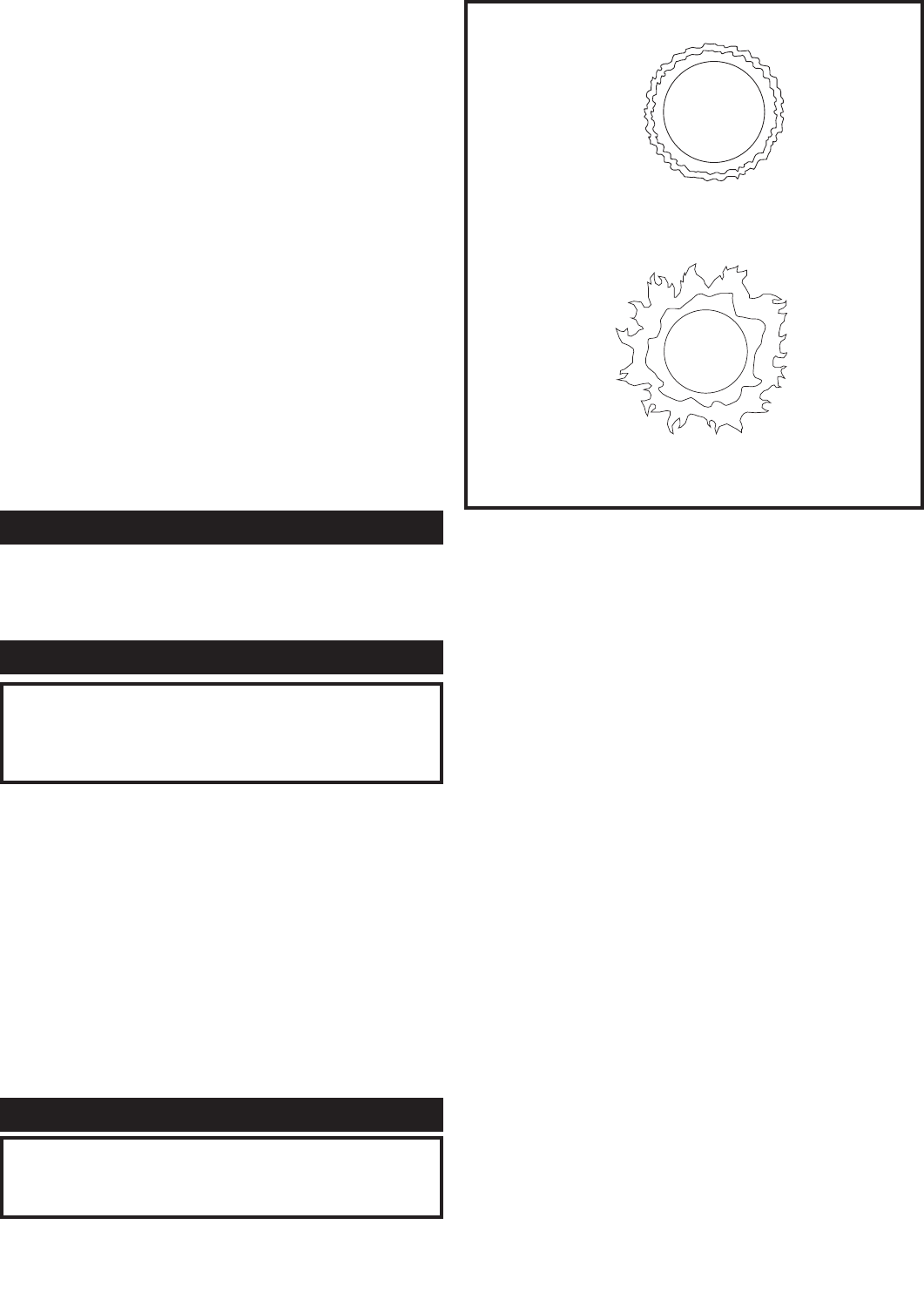

ABNORMAL BURNER FLAME

NORMAL BURNER FLAME

FIG. 76 Flame Pattern

1. Normal Flame: A normal flame at 100% of burner input is blue,

with slight yellow tips a well defined flame and no flame

lifting.

2. Yellow Tip: Yellow tipping can be caused by blockage or

partial obstruction of air flow to the burner.

3. Yellow Flames: Yellow flames can be caused

by blockage of primary air flow to the burner or excessive gas

input. This condition MUST be corrected immediately.

4. Lifting Flames: Lifting flames can be caused by over firing the

burner, excessive primary air or high draft.

If improper flame is observed, examine the venting system, ensure

proper gas supply and adequate supply of combustion and ventilation

air.

C. FLUE GAS PASSAGEWAYS CLEANING

PROCEDURES:

Any sign of soot around the inner jacket, outer jacket, flue pipe

connections, burner or in the areas between the fins on the copper

heat exchanger indicates a need for clean ing. The following

cleaning procedure must only be performed by a qualified

serviceman or installer. Proper ser vice is required to maintain safe

operation. Properly installed and ad just ed units seldom need flue

cleaning.