32

TABLE - Q

Minimum Inlet Water Temperatures

Input Minimum Return Minimum

Btu/hr Temperature Setpoint

1,500,000

___________

1,700,000

___________

2,000,000

105°F (40.6°C)

_______________

90°F (32.2°C)

_______________

70°F (23.9°C)

50°F (10°C)

____________________

50°F (10°C)

____________________

50°F (10°C)

CAUTIONƽ

An appliance allowed to operate at return temperatures

below the specified minimum settings may experience

problems with the operating controls, safety switches,

obstruction of the flue gas passages on the primary heat

exchanger, incomplete combustion and possible flue gas

spillage. Sustained operation at lower than specified

water temperatures may cause hazardous conditions that

may result in personal injury or non-warrantable damage

to the appliance.

A boiler installed above radiation level must be provided with a

low water cutoff device either as part of the unit or at the time of

installation.

WATER FLOW SWITCH

A water flow switch is factory in stalled in the internal bypass piping

on all heating boilers, hot water sup ply boilers and water heaters.

The flow switch is wired in series with the 24 VAC safety control

circuit. This wiring connection installs the flow switch in the 24

VAC safety circuit to prove water flow before main burner ignition.

A factory supplied flow switch installed in the discharge piping

from the top header requires a minimum flow of 26 GPM to make

the flow switch and start burner operation. A water flow switch

meets most code re quire ments for a low-water cut off device on

boilers requiring forced circulation for operation. A status point

alarm of LowH2OFlow will be indicated in the Command Display

on a low water con di tion as sensed by the flow switch.

LOW WATER CUTOFF

(If Equipped)

If this boiler is installed above ra di a tion level, a low water

cut-off device must be installed at the time of boiler installation.

Electronic or float type low water cut-offs are avail able as a factory

supplied option on all models. Low water cut-offs should be

inspected every six months, including flushing of float types. A

status point alarm of LowH2OFlow will be indicated in the

Command Display on a low water condition as sensed by a low

water cutoff.

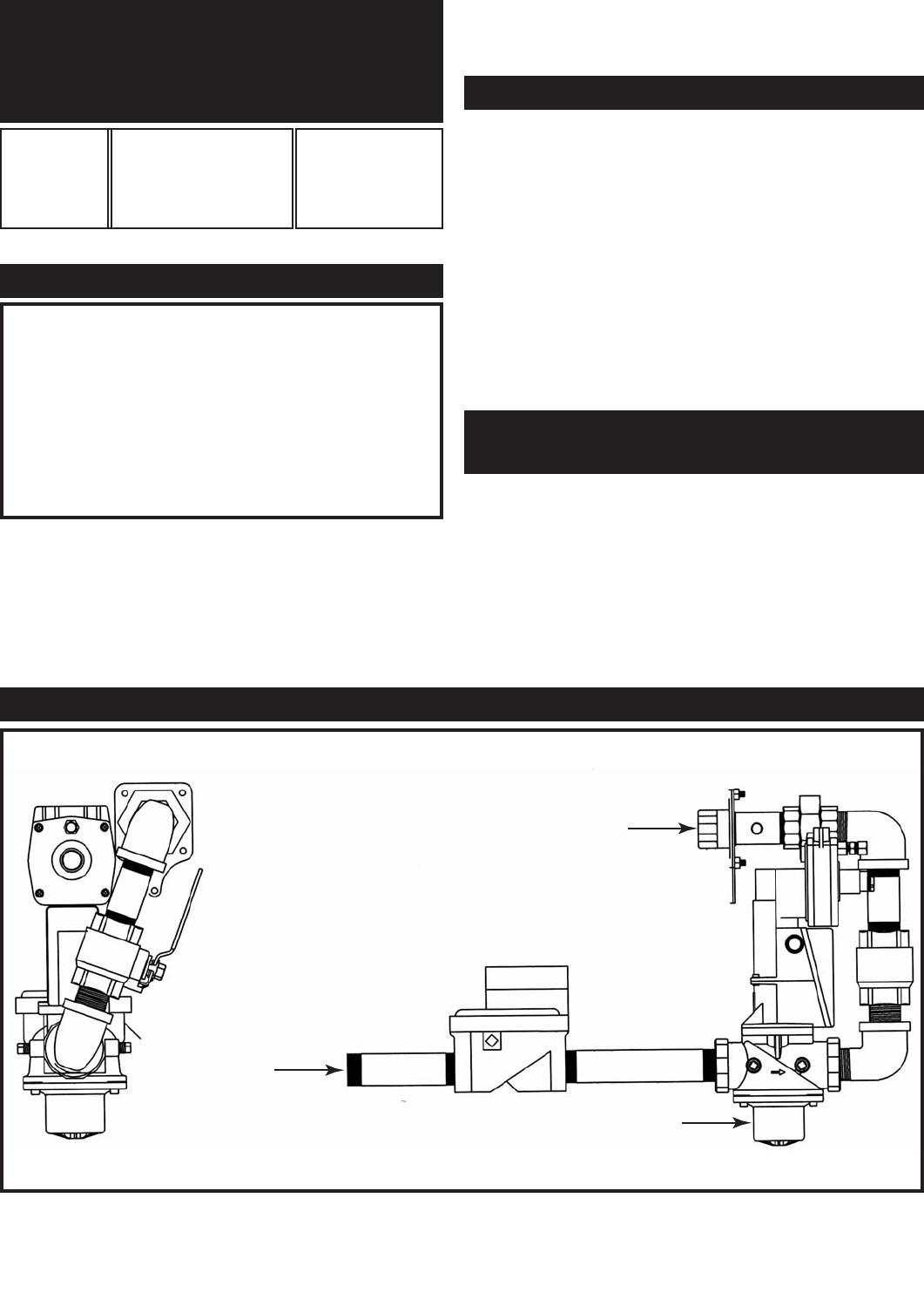

GAS TRAIN AND CONTROLS

DIAPHRAGM

VALVE

ORIFICE

RATIO VALVE

FIG. 42 Gas Train Assembly