25

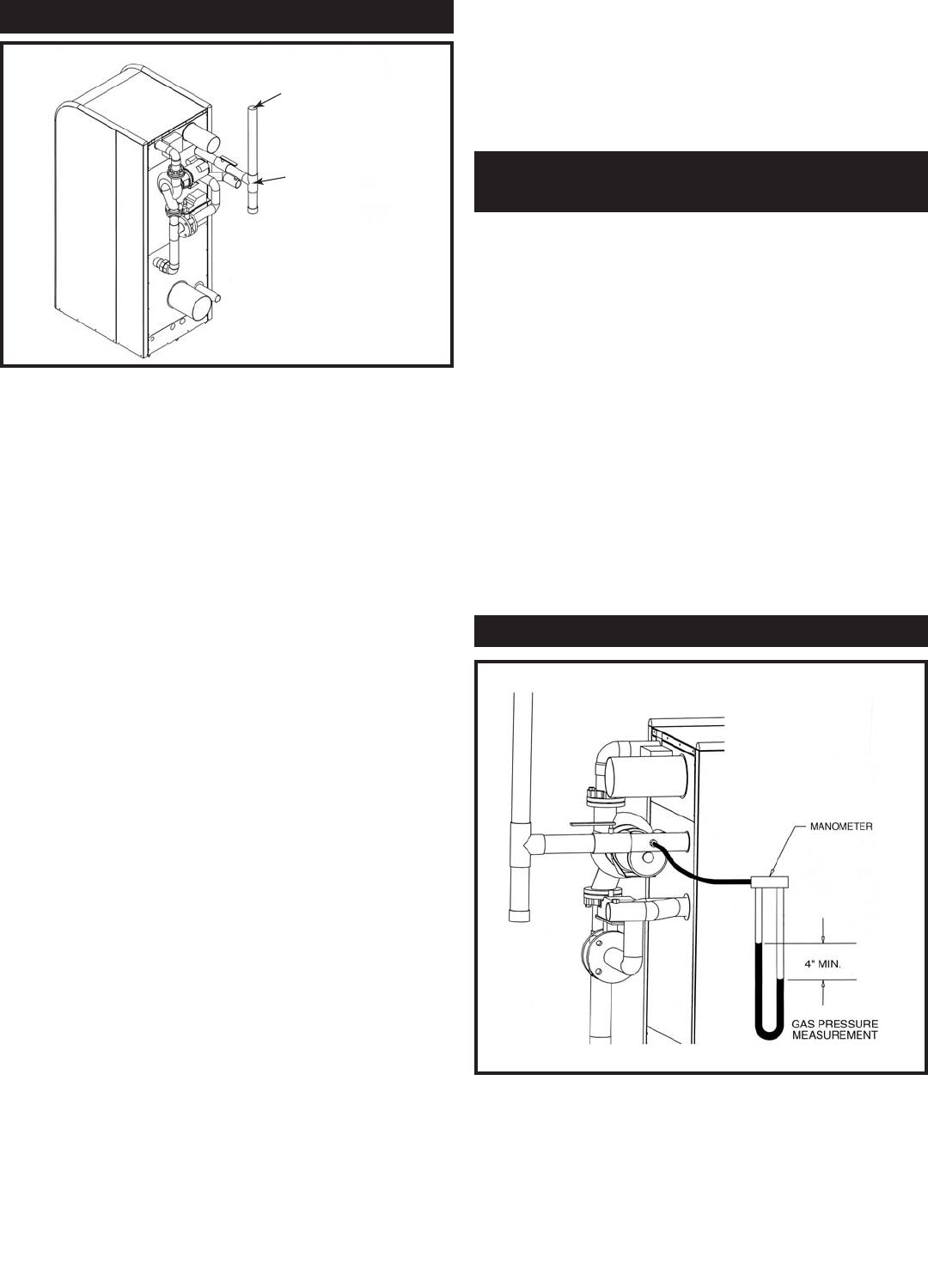

GAS PIPING

TRAP

GAS INLET

FIG. 34 Gas Line Connection to Unit with Sediment Trap

and Manual Main Gas Shut-off Valve

All gas connections must be made with pipe joint compound

resistant to the action of liquefied petroleum and nat u ral gas. All

piping must comply with local codes and ordinances. Tubing

installations must comply with approved standards and practices.

Install Piping to Control

1. The gas line should be a separate line direct from

the meter unless the existing gas line is of

sufficient capacity. Verify pipe size with your gas

supplier.

2. Use new, properly threaded black iron pipe free

from chips. If tubing is used, make sure the ends

are square, deburred and clean. All tubing bends

must be smooth and without deformation. Avoid

flexible gas connections. Internal diameter of

flexible gas lines may not provide appliance with

proper volume of gas.

3. Install a manual main gas shutoff valve at the units

gas inlet, outside of the appliance and before the

gas valve. Install a union at the ap pli ance gas

line connection for ease of service and removal of

the gas train.

4. Run pipe or tubing to the units gas inlet. If tubing

is used, obtain a tube to pipe coupling to connect

the tubing to the units gas inlet.

5. Install a sediment trap in the supply line to the

units gas inlet. (see Figure 34).

6. Remove seal over gas inlet to the appliance.

7. Apply a moderate amount of good quality pipe

compound (DO NOT use Teflon tape) to pipe only,

leaving two end threads bare.

8. Connect gas pipe to inlet of ap pli ance. Use wrench to

support gas man i fold on the appliance.

9. For LP gas, consult your LP gas supplier for expert

installation.

GAS MANIFOLD

PRESSURE ADJUSTMENT

The manifold gas pressure on the Intelli-Fin appliance is not field

adjustable. The ratio gas valve has been factory set with an internal

bias adjustment to ensure a 1:1 air/gas ratio on operation.

Tampering with this adjustment will void the warranty on the gas

valve assembly and the burn er. An Intelli-Fin supplied with a

properly sized gas line, properly sized meter and a minimum of 4

inch water column of gas supply pressure while firing at full rate

will ensure full burner in put. The manifold pressure supplied to the

burner is a differential pressure. This pressure is the result of the

difference in two gas pressure mea sure ments. A differential

manifold gas pressure measurement should not be made until you

have measured the gas supply pressure. Gas supply pressure must

be a minimum of 4 inch water column with all appliances on the

gas line firing at full rate before a manifold pressure measurement

is made. Use the following pro ce dure to check gas supply pressure

with a manometer connected to the inlet pressure tap on the gas line

connection at the rear of the appliance.

CHECKING GAS SUPPLY PRESSURE

FIG. 35 Gas Supply Pressure Measurement