page 7

English

6.1.4 - Unit in stand-by

The control of the unit in stand-by is completely autoĆ

matic thanks to the possibility to connect the Microface

control.

A unit in stand-by starts in the event of an alarm which

stops the main unit; this occurs even if the main unit is

switched off or disappears from the system due to a fault

on the control connecting bus.

The rotation per hour of the units in stand-by occurs

automatically every 24 hours, so as to allow a homogeĆ

neous wear of the system components.

If the system is connected to the Hiromatic interface, it is

possible to set a different rotation control.

If several units are simultaneously working with the same

set point, the temperature used for the control is the

average of the detected ones; further, in the operation

with compressor, the proportional band is divided in as

many parts as twice the number of units belonging to the

system, so as to shut the total available refrigerating

capacity.

The operation in Freecooling mode is homogeneous and

simultaneous on all units.

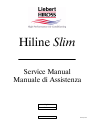

Fig. b, shown as an example, describes the operation of a

system consisting of 3 units.

Fig. b System with 2 units in stand-by -

Microface control

Set _CCoolingHeating

3

Freecooling mode

1

2

3

Compressor cooling mode

11

223

P Band

P Band

Set _CCoolingHeating

1 = main unit

2 = unit in stand-by

3 = unit in stand-by

7 - Refrigerant R22 and oil charge

THESE OPERATIONS MUST BE PERFORMED BY

AN EXPERIENCED REFRIGERATION TECHNIĆ

CIAN.

7.1 - Features of the refrigerating fluid R22

At standard temperature and pressure it is a colourless gas

with low toxicity, non-flammable, and it has an allowed

exposure limit value (AEL/TLV) corresponding to 1000

ppm (average value measured on 8 hours/day). In the

event of leakage, air the room before use.

7.2 - Refrigerant charge

WHEN REPAIRING THE REFRIGERATION CIRĆ

CUIT RECUPERATE ALL REFRIGERANT IN A CONĆ

TAINER: DO NOT ALLOW IT TO ESCAPE.

1) Start the unit as described in par. 4.1.

2) Start the compressor manually.

3) Guarantee a constant condensation temperature

(preferably 42-45°C); if necessary, partially obstruct

the condenser coil surface or limit its ventilating

power to obtain these conditions.

4) Charge the unit with the quantity of refrigerant R22

as shown in Tab. 5 and wait until the operating condiĆ

tions of the whole refrigeration circuit are normal.

5) Check that the overheating is 7-8°C.

Tab. 5 - Refrigerant charge

MODEL

PKS3 PKS4

Refrigerant charge (g)

1500 1700

7.3 - Oil charge

The oil to be used when topping up is SUNISO 3GS; if

SUNISO 3GS is unavailable use an oil with the same

characteristics (see Tab. 6).

NEVER MIX DIFFERENT OILS TOGETHER.

CLEAN THE PIPING COMPLETELY BEFORE

CHANGING THE TYPE OF OIL USED.

Tab. 6 - Suniso 3GS oil (standard)

approx. specific weight (at 15_C)

flash point (C.O.C.)

pour point

ENGLER viscosity at 50 _C

viscosity index

copper corrosion (100 _C, 3 hours) ASTM D130

neutralization value

conradson carbon residue

dielectric strength

:

:

:

:

:

:

:

:

:

0.91 kg/l

170 _C

-40 _C

2.7 E

0

1

0.03 max.

0%

> 30 kV