8. After piping has been properly connected to the water

heater, open the nearest hot water faucet. Then open the

cold water shut off valve and allow the tank to completely

fill with water. To purge the lines of any excess air and

sediment, keep the hot water faucet open for 3 minutes

after a constant flow of water is obtained. Close the faucet

and check all connections for leaks.

Please note the following:

• The system should be installed only with piping that is

suitable for potable (drinkable) water such as copper,

CPVC, or polybutylene. This water heater must not be

installed using iron piping or PVC water piping.

• Use only pumps, valves, or fittings that are compatible with

potable water.

• Use only full flow ball or gate valves. The use of valves

that may cause excessive restriction to water flow is not

recommended.

• Use only 95/5 tin-antimony or other equivalent solder. Any

lead based solder must not be used.

• Piping that has been treated with chromates, boiler seal, or

other chemicals must not be used.

• Chemicals that may contaminate the potable water supply

must not be added to the piping system.

Property Damage Hazard

• Avoid water heater damage.

• Install thermal expansion tank if necessary.

• Do not apply heat to cold water inlet.

• Contact qualified installer or service agency.

Condensate Drain Line Installation

Install two 1/2" PVC discharge lines from the condensate drains

(located on the right side near the back). The lines should

terminate a maximum of six inches above an adequate drain.

Do not discharge the condensate drain lines into the metal drain

pan. If no floor drain is available or the drain is above the level

of the condensate line, a condensate pump should be installed.

These pumps are available from local distributors.

When installing the drain line, note the following:

• Plastic pipe or tubing must be used to connect the

condensate drain to a suitable drain or condensate pump.

• Condensate drain lines should be installed in conditioned

areas only. Install approved insulation on the condensate

drain lines to prevent condensation from forming on the

outside of the drain lines. Condensation drain lines installed

in areas that are subject to freezing temperatures should

be wrapped with a nationally recognized/listed heat tape.

Install per manufacturer's instructions.

• Do not connect condensate drain lines with other drain or

discharge lines into a single (common) pipe or line. Each

line (condensate drain line, temperature and pressure relief

valve discharge pipe, etc) should be independently run to

an adequate drain.

• Slope the condensate drain lines toward the inside floor

drain or condensate pump.

• The condensate drain lines and connections to the drain

piping must comply with all local codes.

• Use appropriate primer and glue to cement the condensate

drain lines to the heat pump drain pan. NOTE: The heat

pump drain pan is ABS and the two condensate drain pipes

should be PVC.

• If a condensate pump is installed it should shut off the

heat pump in the event the condensate pump fails or the

float switch in the pump activates (See "Condensate Pump

Installation" section.)

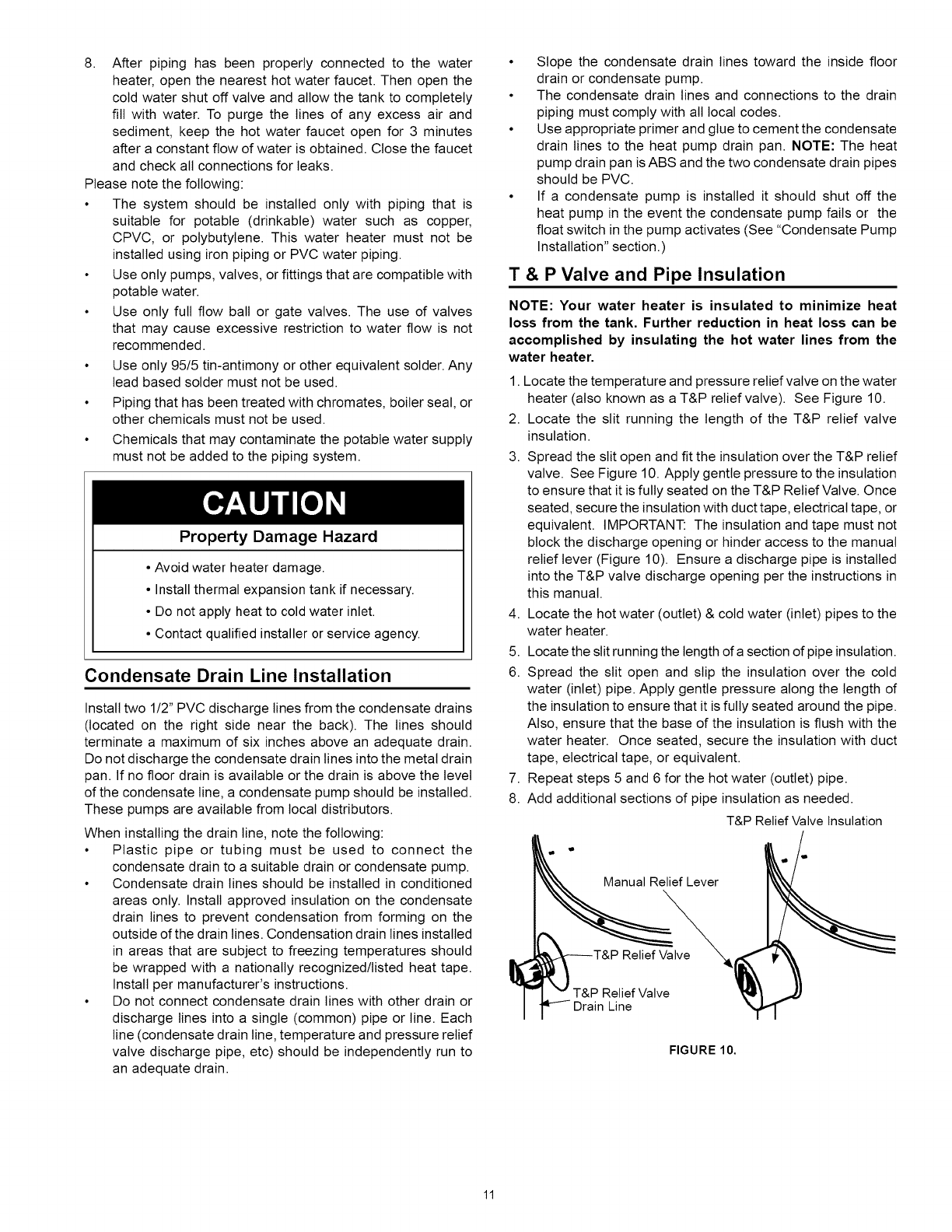

T & P Valve and Pipe Insulation

NOTE: Your water heater is insulated to minimize heat

loss from the tank. Further reduction in heat loss can be

accomplished by insulating the hot water lines from the

water heater.

1. Locate the temperature and pressure relief valve on the water

heater (also known as a T&P relief valve). See Figure 10.

2. Locate the slit running the length of the T&P relief valve

insulation.

3. Spread the slit open and fit the insulation over the T&P relief

valve. See Figure 10. Apply gentle pressure to the insulation

to ensure that it isfully seated on the T&P Relief Valve. Once

seated, secure the insulation with duct tape, electrical tape, or

equivalent. IMPORTANT: The insulation and tape must not

block the discharge opening or hinder access to the manual

relief lever (Figure 10). Ensure a discharge pipe is installed

into the T&P valve discharge opening per the instructions in

this manual.

4. Locate the hot water (outlet) & cold water (inlet) pipes to the

water heater.

5. Locate the slit running the length of asection of pipe insulation.

6. Spread the slit open and slip the insulation over the cold

water (inlet) pipe. Apply gentle pressure along the length of

the insulation to ensure that it is fully seated around the pipe.

Also, ensure that the base of the insulation is flush with the

water heater. Once seated, secure the insulation with duct

tape, electrical tape, or equivalent.

7. Repeat steps 5 and 6 for the hot water (outlet) pipe.

8. Add additional sections of pipe insulation as needed.

T&P Relief Valve Insulation

ef Lever

veX

Relief Valve

Drain Line

FIGURE 10.

11