8

Vent Restriction

The GF 400 DV Sebago is equipped with Restrictor Plates

which enable you to regulate the flow of incoming

combustion air and exhaust gas. The plates prevent

overly strong draft that can cause poor combustion and

weak flame picture. Follow the guidelines below, and on

the following pages, to determine the correct restrictor

plate setting for your particular installation configura-

tion.

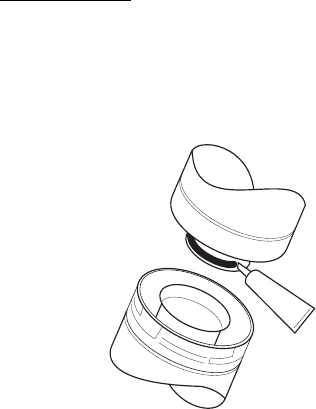

Intake Air Restrictor

This plate is located at the rear of the firebox behind the

burner plate. It is set in a CLOSED position at the factory

and should be left there for most vent configurations.

It should be opened only for snorkel terminations and

some short run horizontal terminations as specified on

the following pages. To adjust the Air Restrictor to the

OPEN position, locate and loosen the wing nut under the

burner and push it back as far as it will go. See Fig. 6.

Exhaust Restrictor

The Exhaust Restrictor is an adjustable shutter located at

the top of the firebox. It is adjusted by moving a pivot

pin into one of four positions. It is set in the FULLY OPEN

position at the factory. See Fig. 7.

Use the chart in Table 1 to determine the correct

position for your installation and follow the instructions

below to adjust it if necessary.

Additional restriction may be needed depending the

overall vent height. Use Simpson Dura-Vent Restrictor

Disk #929.

Adjusting Exhaust Restrictor Plate:

1. Remove the Top Plate.

2. Locate the pivot pin at the left side of the firebox top.

Loosen the wing nut on the pivot pin and push the pin

to the left to disengage it from the current setting

position. Move the pin toward the rear and then right

to engage it in the appropriate position indicated on

the firebox. See fig. 7.

3. Tighten the lock nut and replace the Top Plate.

Venting Requirements

The Jøtul GF 400 DV Sebago gas stove may be installed

with a vertical or horizontal termination and must

conform to the configuration requirements described

below.

This appliance is approved for use with vent systems

from the following manufacturers:

• Simpson Dura-Vent GS

• Amerivent Corporation

• Security Vent Ltd.

• Selkirk Metalbestos

Use parts of one manufacturer only - DO NOT MIX

VENT COMPONENTS FROM DIFFERENT MANUFACTURERS

IN THE SAME SYSTEM.

Installation of any components not manufactured or

approved by Jøtul or failure to meet all clearance require-

ments will void all warranties and could result in prop-

erty damage, bodily injury, or serious fire.

The approved vent configurations described in this

manual are derived from extensive testing under con-

trolled laboratory conditions. Gas appliance performance

can be negatively affected by variables present in the

installation environment, i.e: atmospheric pressure,

strong prevailing winds, adjacent structures and trees,

snow accumulation, etc. These conditions should be

taken into consideration by the installer and stove owner

when planning the vent system design.

IMPORTANT

• JOINT SEALING REQUIREMENT: APPLY A 1/8” BEAD OF

HIGH-

TEMPERATURE (750°F) SEALANT TO THE MALE SEC-

TION OF THE INNER VENT PIPE. THE CEMENT SHOULD

FORM A SEAL BETWEEN THE INNER

AND OUTER PIPES.

• NEVER MODIFY ANY VENTING

COMPONENT, OR USE ANY DAM-

AGED VENTING PRODUCT.

• THE GAS APPLIANCE AND VENT

SYSTEM MUST BE VENTED

DIRECTLY TO THE OUTSIDE OF

THE BUILDING AND NEVER

ATTACHED TO A CHIMNEY

SERVING A SOLID FUEL OR

GAS BURNING APPLIANCE.

EACH DIRECT VENT GAS APPLIANCE

MUST HAVE ITS OWN SEPARATE VENT SYSTEM.

COMMON VENT SYSTEMS ARE PROHIBITED.

• IF VENTING SYSTEM IS DISASSEMBLED FOR ANY

REASON, REINSTALL PER THE INSTRUCTIONS PROVIDED

FOR THE INITIAL INSTALLATION.

S

E

A

L

A

N

T

Fig. 5.