NOTES:

1. Refer to the condensate management and drain hose

plumbing for different configurations in this document. No

hose clamps are needed for the condensate pan hook up.

2. Drip leg in the gas line must be installed.

3. The furnace controls require correct polarity on the power

supply and a proper ground.

4. Y & G must be connected to the control board for cooling

operation.

5. To measure total static pressure add supply duct pressure to

the return duct pressure, add pressure drop across the ‘A’

coil, and add pressure drop across the filter. Ignore negative

signs on the readings.

6. Inlet gas pressure for natural gas should be 7” and that for

propane should be 11” w.c. Nominal manifold gas pressure

is 3.5” for natural gas and 10” w.c. for propane.

7. If thermoplastic evaporator ‘A’ coil drain pans are to be

installed in the up-flow/horizontal configuration, then extra 2”

minimum spacing may be needed to ensure against drain

pan distortion.

8. External filters required on all configurations.

9. Electrical entry is available on both sides of the casing.

10. All 33”, 95% furnaces are approved for single-pipe and 2-

pipe systems. For single pipe systems it is recommended to

install the combustion air coupling provided and install

approximately 18” of PVC pipe on the furnace.

11. Do not install an external condensate trap on these fur-

naces, as it will prevent the unit from operating correctly.

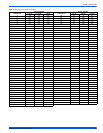

Models

Airflow CFM (Bottom Return without Filters)

Minimum Wire

Size awg @ 75'

One-Way

Total Unit

Amps

Maximum

Over Current

Protection

0.5" ESP (Nominal)

Low Med-Lo Med-Hi High

(T,G)G9S040A08MP11 581 653 818 950 14 8.0 15

(T,G)G9S060A10MP11

769 917 1038 1103 14 10.0 15

(T,G)G9S060B12MP11

713 872 1082 1243 14 10.0 15

(T,G)G9S080B12MP11 854 1008 1179 1370 14 10.0 15

(T,G)G9S080C16MP11

838 1250 1465 1671 14 11.5 15

(T,G)G9S080C22MP11

1285 1586 1937 2162 12 17.0 20

(T,G)G9S100C16MP11 819 1224 1477 1706 14 11.5 15

(T,G)G9S100C20MP11

1183 1430 1712 1934 12 17.0 20

(T,G)G9S120D16MP11

876 1254 1495 1805 14 11.5 15

(T,G)G9S120D20MP11 1190 1430 1739 1977 12 17.0 20

(T,G)G9S130D20MP11

1198 1459 1786 2047 12 17.0 20

Models

Maximum

Vent Equivalent

1

Factory Heating

Speed Setting

2

Temperature

Rise Range

Time For 1 ft

3

Natural Gas

(1030 Btu/Ft

3

)

Seconds On (Rate)

2" 3"

(T,G)G9S040A08MP11 65’ 90’ Med-Hi 30°F-60°F 93

(T,G)G9S060A10MP11 65’ 90’ High 30°F-60°F 62

(T,G)G9S060B12MP11 65’ 90’ Med-Hi 30°F-60°F 62

(T,G)G9S080B12MP11 65’ 90’ High 35°F-65°F 46

(T,G)G9S080C16MP11 65’ 90’ High 35°F-65°F 46

(T,G)G9S080C22MP11 65’ 90’ Med-Hi 35°F-65°F 46

(T,G)G9S100C16MP11 30’ 90’ High 35°F-65°F 37

(T,G)G9S100C20MP11 30’ 90’ Med-Hi 35°F-65°F 37

(T,G)G9S120D16MP11 30’ 90’ High 40°F-70°F 30

(T,G)G9S120D20MP11 30’ 90’ Med-Hi 35°F-65°F 30

(T,G)G9S130D20MP11 N/A 85’ High 45°F-75°F 28

1. For venting purposes, one 90° sweep elbow is equal to 5 Ft. of venting length, one 90° standard elbow is equal to 10 equiva-

lent feet of vent length. Vent termination elbows are not included in these calculations, minimum required vent length is 15 ft.

2. Must be changed if not in rise range.

This document does not replace the installation instructions, which must be referred to for

detailed information.

CLEARANCES

* 24" clearance in front and 18" on side recommended for

service access.

All furnaces approved for alcove and attic installation.

DIMENSIONS

LED INDICATOR

Slow Green Flash

• Normal operation

Slow Amber Flash

• Normal operation with call for heat

Any Red Flash = Fault condition

Any Rapid 4 Flash = Potential fault codes / conditions

SUPPLY END

RETURN END

LEFT SIDE

Combustion Air Inlet

Condensate Drain

(Downflow)

Vent Connection

Outlet

Thermostat

Wiring

29.5”

28.5”

RIGHT SIDE

Condensate Drain

(Downflow)

14”

1”

1.5”

23”

Combustion Air Inlet

Gas Pipe

Entry

Electrical

Entry

Condensate

Drain

Optional Return Air

Cutout (Either side)

FRONT

A

33”

Clips can be flipped

into the up position

for coil cabinet or

plenum attachment

A-COIL

Follow all national, local codes and standards in addition to this document. The installation

must comply with regulations of the serving gas supplier, local building, heating, plumbing,

and other codes. In absence of local codes, the installation must comply with the national

codesand allauthorities havingjurisdiction.

B

24.25”

.56”

.56”

20”

3”

23.8”

.56”

Combustion

Air Inlet

2” Diameter

Vent Connection

Outlet

B

DURING INSTALLATION,

DOORS MUST REMAIN ON

FURNACE WHEN MOVING

OR LIFING.

Vent Connection

Outlet

Application Upflow Downflow Horizontal

Top 1" 0" 0"

Vent 0" 0" 0"

Rear 0" 0" 0"

Side 0" 0" 1"

Front* 0" 0" 0"

Floor Combustible

Combustible

1

1. For combustible floors only when used with special

sub-base.

Combustible

Closet Yes Yes Yes

Line Contact No No Yes

Cabinet Size A (in) B (in)

All 'A' Cabinet Furnaces 14-1/2" 13-3/8"

All 'B' Cabinet Furnaces 17-1/2" 16-3/8"

All 'C' Cabinet Furnaces 21" 19-7/8"

All 'D' Cabinet Furnaces 24-1/2" 23-3/8"

QUICK REFERENCE GUIDE

95.5% SINGLE STAGE MULTI-POSITION

RESIDENTAL GAS FURNACES (33” TALL)

Subject to change without notice. Printed in U.S.A. 401260-URG-C-0808

Copyright © 2008 by Johnson Controls, Inc. All rights reserved. Supersedes: 401260-URG-B-0708

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 73069

*401260*