9

MAIN CHARACTERISTICS OF FREQUENCY CONVERTERS USED IN THE

PHV BOOSTER SETS

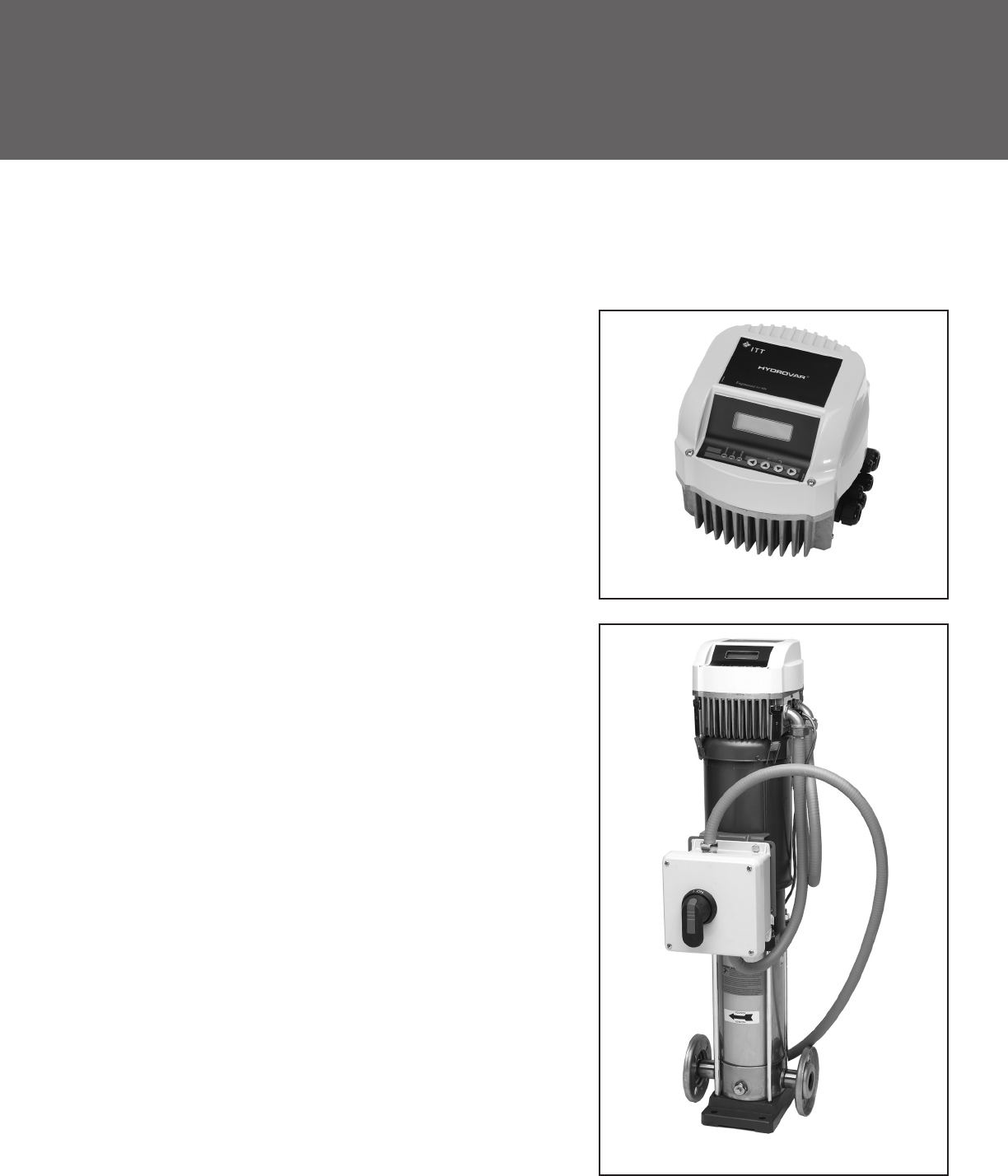

The PHV series booster sets use a Hydrovar

®

variable frequency drive, an automatic device that adjusts the speed of the

electric pump in order to maintain constant pressure in the system.

Converters with power up to 30 HP can be mounted directly on

to the motor. Models with over 30 HP power, are designed for wall

mounting only. The pressure is measured by a pressure transmitter

which uses a standard 4..20 mA current signal. The system pressure

value can be read on the converter’s display. A simple user interface

allows you to set the desired pressure value for optimal adjustment,

as well as to view the operating data, such as the hours of

operation and any alarms triggered. Included diagnostic menu to view

temperature, current and voltage values facilitates diagnostics and

failure analisys. Indicator lights signal power status, pump running and

malfunctions.

A password is required to access sensitive settings that allow you

to program the Hydrovar in order to adapt it to any control

requirements, such as flow resistance compensation, external

control, periodic testing and so on. When more than one pump is

used, the converters exchange information with each other through an

RS485 serial line which can connect up to 8 Hydrovar devices plus

one external unit for remote control. The Pump-link and Pump-watcher

dedicated systems, connected to the Hydrovar®, enable remote

control through a traditional telephone line or mobile telephony. A

serial port available as standard up to 15 HP allows you to control the

Hydrovar® converters from a Modbus

®

field serial bus line.

The converter is equipped with two potential-free relays which can

be used for remote signalling of pump running and malfunction

status, plus a programmable voltage analogue output for signalling

the frequency or pressure. Standard version with two sensor inputs

for implementing of two actual values signals within one system (min/

max, difference) or for a second sensor for safety reasons. Specific

digital inputs are used for protection against water failure, motor

overtemperature, as well as for external enable signal and remote

control. The converter also incorporates a dry running protection

function via an adjustable minimum pressure threshold.

FCC Class A filter standard for Hydrovar three-phase power supply.

E.g. Industrial areas, technical areas of any building fed from a

dedicated transformer are examples of environment locations.

FCC Class B filter standard for Hydrovar single-phase power supply.

E.g. Houses, apartments, commercial premises or offices in a residential building are examples of environment locations.

Further information is available in the Hydrovar manual.

PHV Series Hydrovar with SSV Pump

Modular Hydrovar, Bare Unit