Page 2 of 8 65178X-XXX-B (en)

OPERATING AND SAFETY PRECAUTIONS

Read and heed all warnings, cautions and safety pre-

cautions before operation of this unit.

Be certain anyone operating this equipment or fluid

system has been trained to use it safely.

WARNING

HIGH PRESSURE DEVICE. Improper usage of

this equipment could result in serious injury. The pos-

sibility of injection into the esh is a potential hazard.

Wear approved safety glasses or face shield and other

equipment as needed to prevent injury. Never al-

low any part of the human body to come in front of

or in contact with the material outlet, the tip, or the

material outlet of the dispensing device. An injection

injury can be serious. If an injection accident should

occur, it is very important that you contact a quali ed

physician for immediate treatment.

WARNING

MISAPPLICATION HAZARD. Do not use the

regulator when the uid inlet pressure is too high for

the designed operating range. Excessive inlet pres-

sure can cause a lock-out situation. Lock-out occurs

when the inlet pressure is beyond the regulator’s

spring capacity. The valve will not open. Attempts to

disassemble components while in a lock-out condi-

tion may result in injury.

WARNING

COMPONENT RUPTURE. Do not operate

regulator at an inlet pressure greater than speci ed.

To avoid possible damage or personal injury do not

operate this unit at pressure higher than the stated

operating range as it appears on the model plate.

INSTALLATION

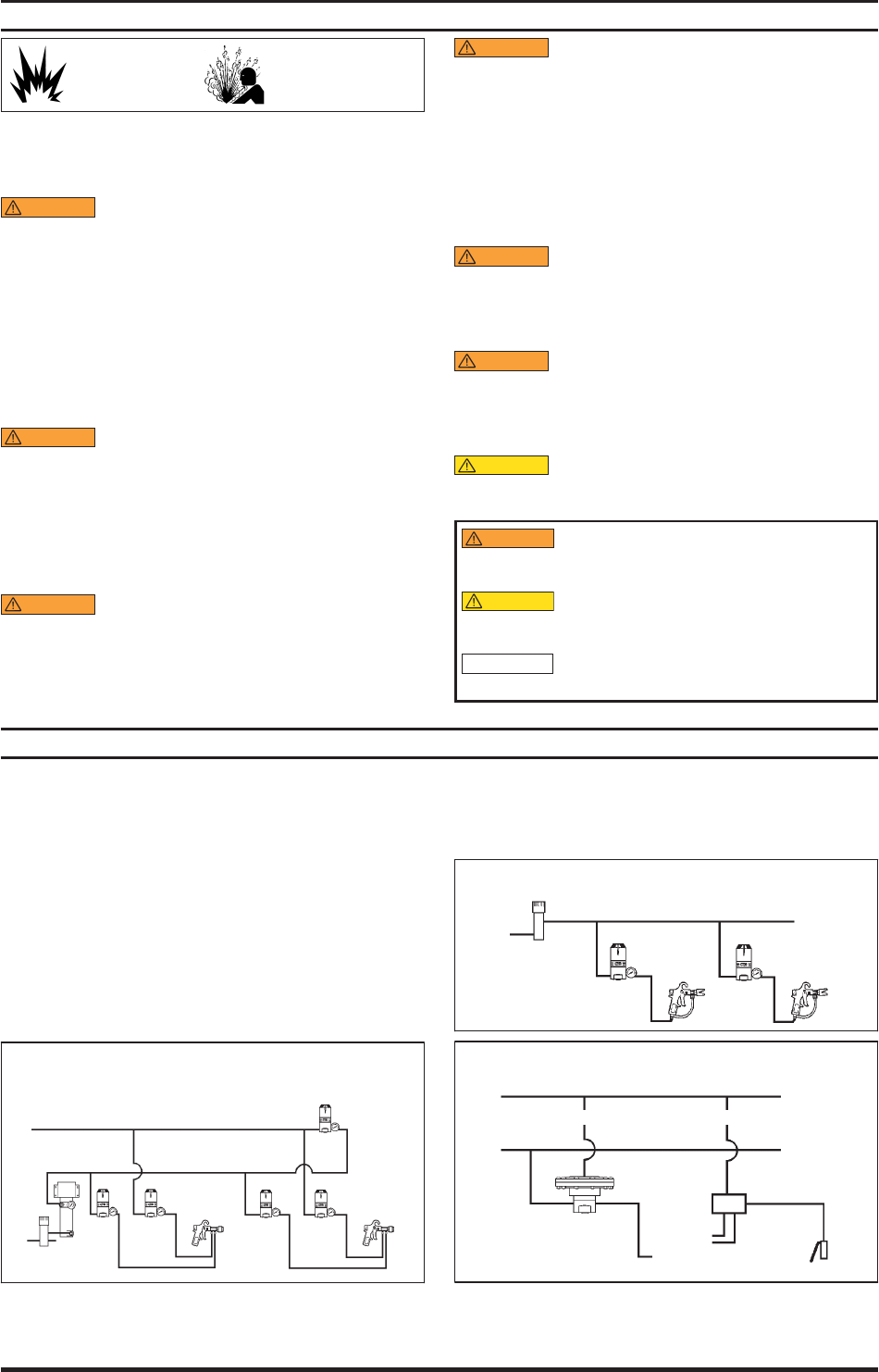

Figure 2

WARNING

DISASSEMBLY HAZARD. Do not disassemble

this regulator when it is under pressure. Relieve pres-

sure in the pumping system before attempting service

or disassembly procedures. Disconnect air lines and

carefully bleed pressure o the system. Be certain the

system is not maintaining pressure due to a material

restriction in the hose, line, dispensing device, or the

spray or extrusion tip. Failure to relieve pressure both

up stream and downstream may result in an injury

upon disassembly.

WARNING

BONNET REMOVAL HAZARD. Do not at-

tempt to remove the four bonnet retaining bolts

without rst relieving the tension on the main spring.

Failure to relieve tension could result in an accident

upon disassembly.

WARNING

PREVENT FIRES. Keep solvents away from

heat, sparks or open flame. Keep containers closed

when not in use. When pumping, flushing or recir-

culating volatile solvents, be certain the area is ad-

equately ventilated.

CAUTION

FLUSH SUPPLY LINE. Before installing uid

regulator blow the supply lines clear and ush to re-

move contaminates.

WARNING

= Hazards or unsafe practices which

could result in severe personal injury,

death or substantial property damage.

CAUTION

= Hazards or unsafe practices which

could result in minor personal injury,

product or property damage.

NOTICE

= Important installation, operation or

maintenance information.

Refer to the typical installation view which best applies.

Locate the regulator as close as possible to the spray gun

or dispensing device for best pressure control.

Identify the regulator INLET / OUTLET (flow direction).

The regulator is marked with an arrow on the body base

(refer to gure 10).

When flexible fluid lines are used, mount the regulator

securely using the (2) 1/4” - 20 threaded holes in the base

(see gure 10).

Flush supply line before installing regulator.

Remote models require maximum 100 p.s.i. (6.9 bar)

signal pressure. Start with a signal pressure as low as pos-

sible and adjust upward until proper ow is reached.

TYPICAL RECIRCULATING SYSTEM

Back Pressure

Regulator

Back Pressure

Regulator

Back Pressure

Regulator

Down

Stream

Regulator

Down

Stream

Regulator

Heater

Filter

EXCESSIVE AIR PRESSURE

STATIC SPARK

HAZARDOUS MATERIALS

HAZARDOUS PRESSURE

TYPICAL DEAD END SYSTEM

Down

Stream

Regulator

Down

Stream

Regulator

Filter

TYPICAL REMOTE SYSTEM

Filter

Remote

Regulator

Automatic

Extrusion Gun

Limit Switch

4-Way Valve

(Material)

(Air)

F-R-L

F-R-L

ARO® is a registered trademark of Ingersoll Rand Company Loctite® and 242® are registered trademarks of Henkel Loctite Corporation

271™ and 680™ are trademarks of Henkel Loctite Corporation Hytrel® is a registered trademark of the DuPont Company

Perma-lok® is a registered trademark of National Starch and Chemical Corporation