35

icos - Installation & Servicing

SERVICING

50

CLEANING THE HEAT EXCHANGER

49

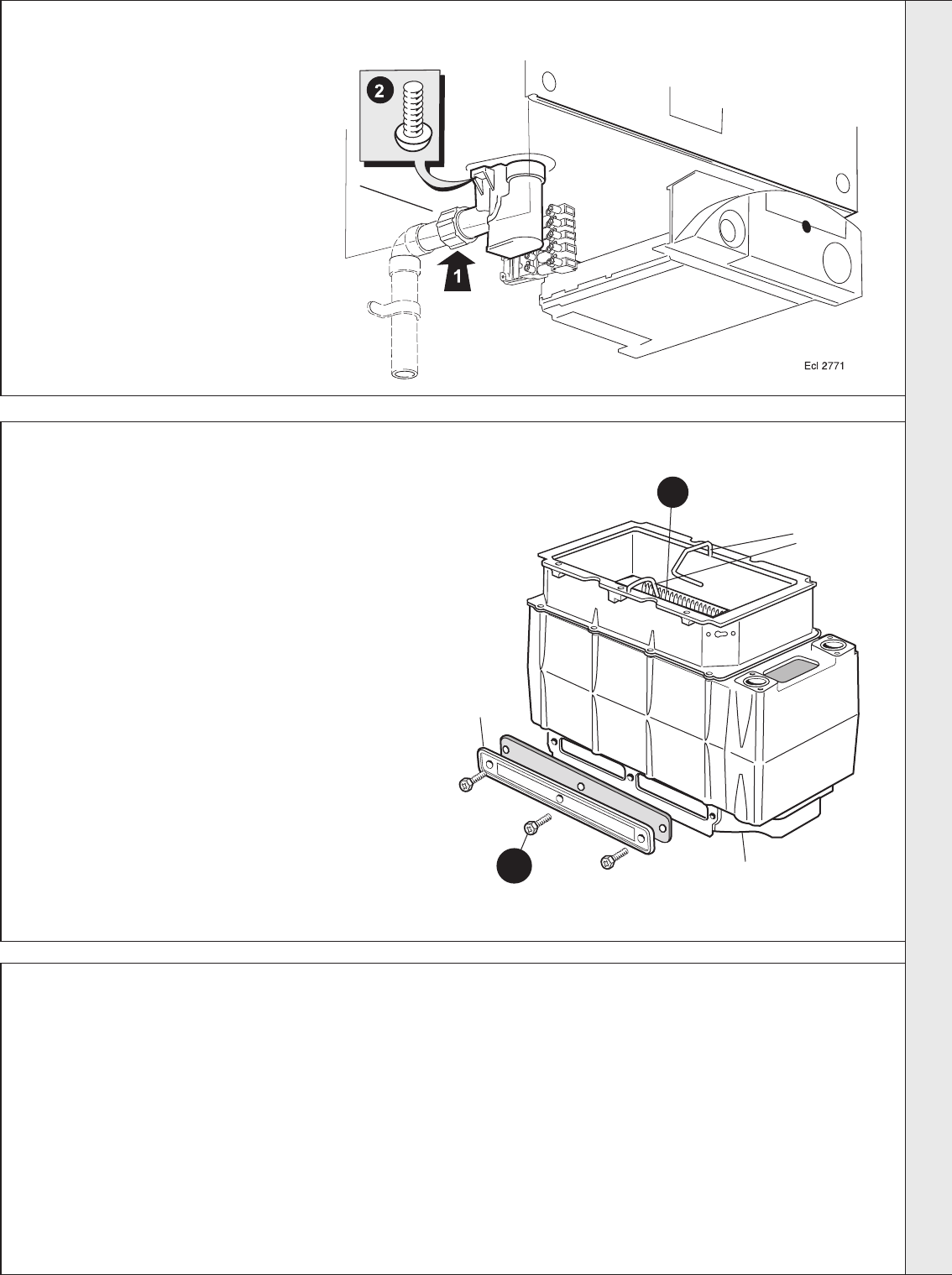

CLEANING THE CONDENSATE 'S' TRAP

1. Undo the plastic union nut on

the condensate ‘S’ trap outlet.

2. Remove the 2 screws.

3. Pull the trap down and forward

to remove.

4. Flush out any deposits with

clean water.

51

REASSEMBLY

Reassemble the boiler in the following order.

1. Refit the condensate ‘S’ trap, ensuring that it is full of water.

2. Refit the sump cover plate.

3. Refit the electrodes (check dimensions Frames 56 & 57).

4. Refit the burner.

5. Refit the fan / venturi assembly.

6. Reconnect the fan electrical leads.

7. Refit the boiler sealing panel.

IMPORTANT.

Ensure the boiler sealing panel is correctly fitted and

that a good seal is made.

8. Refit the boiler front and bottom panels.

9. Turn on the gas supply at the gas service cock.

10.Reconnect the electrical supply.

1. Remove ignition and flame detection electrodes.

Refer to Frames 56 & 57.

2. Remove the 3 screws retaining the sump cover and

remove.

3. Using a suitable tool as supplied in the standard

British Gas Flue brush kit, clean between the heat

exchanger fins from the top of the heat exchanger.

4. Access to the base of the heat exchanger is now

possible. Brush clean any deposits from the base of

the heat exchanger and remove any loose deposits

from the sump.

5. Inspect the ignition and detection electrodes. Ensure

that they are clean and in good condition - replace if

necessary.

6. Check the condition of the combustion chamber

insulation. Any cracked or damaged pieces must be

replaced.

Note. Take care not to disturb the ionisation probes at the

front and rear of the combustion chamber.

7. Check that the ignition and detection gaps are

correct. Refer to Frames 56 & 57.

nm7401

2

Sump cover

3

Ionisation

probes

Heat exchanger

SERVICING