11

icos - Installation & Servicing

GENERAL

Non-return

valve

Automatic

air vent

Hose unions

Additional

stop valve

Hose connector

Hosepipe

(disconnect

after filling)

Double check valve

assembly

(note direction of flow)

Temporary hose

(disconnect

after filling)

ecl6060

Note. The pump manufacturers' minimum requirements must be complied with.

5

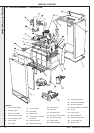

LOW HEAD AND LARGE SYSTEMS WITH EXTENSIVE PIPE RUNS - OPEN VENT

All dimensions in mm (in.).

NB. Imperial dimensions are approximate

6

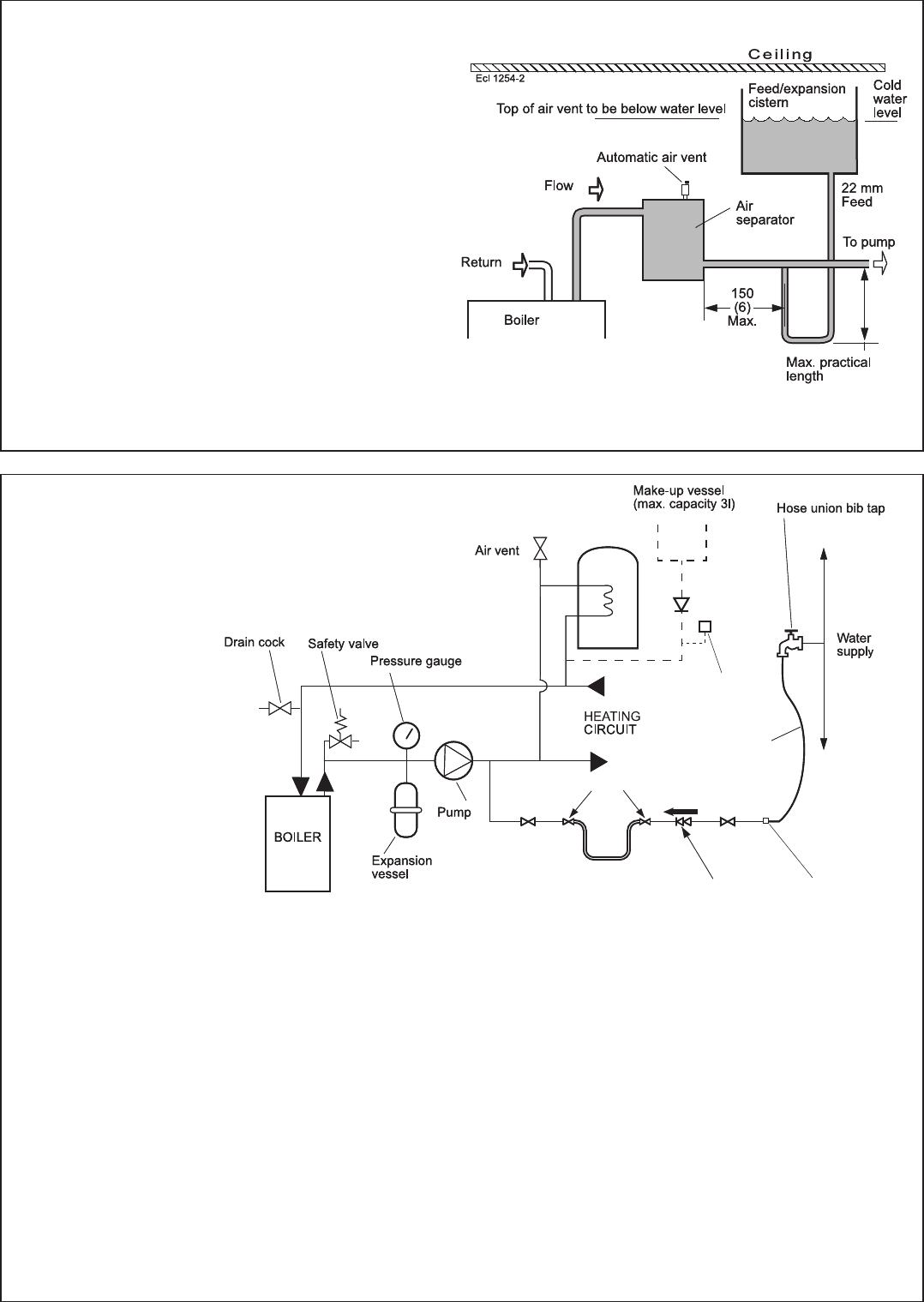

SEALED SYSTEM REQUIREMENTS

This arrangement is useful for large systems where

radiators at the extremities are difficult to vent. This can

lead to pumping over with conventional feed and vent

arrangements.

The following conditions MUST be observed:

1. The top of the automatic air vent must be below the

cold water level.

2. The static water level (cold) must be at least 200mm

above the top of the horizontal flow pipe, fitted as

shown. The vent connection MUST NOT be made

immediately off the top of the boiler as venting is

made less efficient.

3. The maximum practical length of 22mm cold feed pipe

should be used in order to reduce the effective volume

of hot system water expanding into the feed/expansion

cistern to a minimum.

a. A non-adjustable preset lift pressure not exceeding

3bar (45lb/in

2

).

b. A manual testing device.

c. Provision for connection of a discharge pipe.

The valve or discharge pipe should be positioned so

that the discharge of water or steam cannot create a

hazard to the occupants of the premises or cause

damage to electrical components and wiring.

3. Pressure Gauge

A pressure gauge covering at least the range 0-4 bar

(0-60 lb/in

2

) must be fitted to the system. The gauge

should be easily seen from the filling point and should

preferably be connected at the same point as the

expansion vessel.

Notes.

a. The method of filling, refilling, topping up or flushing

sealed primary hot water circuit from the mains via a

temporary hose connection is

only allowed if

acceptable to the

local water authority.

b. When installing the

filling device, it must be

connected as shown to

fully comply with the

water regulations. This

may involve the fitting of

an additional WRAS

approval isolator valve

to the mains supply.

1. General

a. The installation

must comply with the

requirements of BS. 6798

and BS. 5449.

b. The installation should be designed to work with

flow temperatures of up to 82

o

C.

c. All components of the system, including the heat

exchanger of the indirect cylinder, must be

suitable for a working pressure of 3 bar (45lb/in

2

)

and temperature of 110

o

C. Care should be taken

in making all connections so that the risk of

leakage is minimised.

2. Safety Valve

A spring loaded safety valve complying with the

relevant requirements of BS. 6759 must be fitted in

the flow pipe as close to the boiler as possible and

with no intervening valve or restriction. The valve

should have the following features: