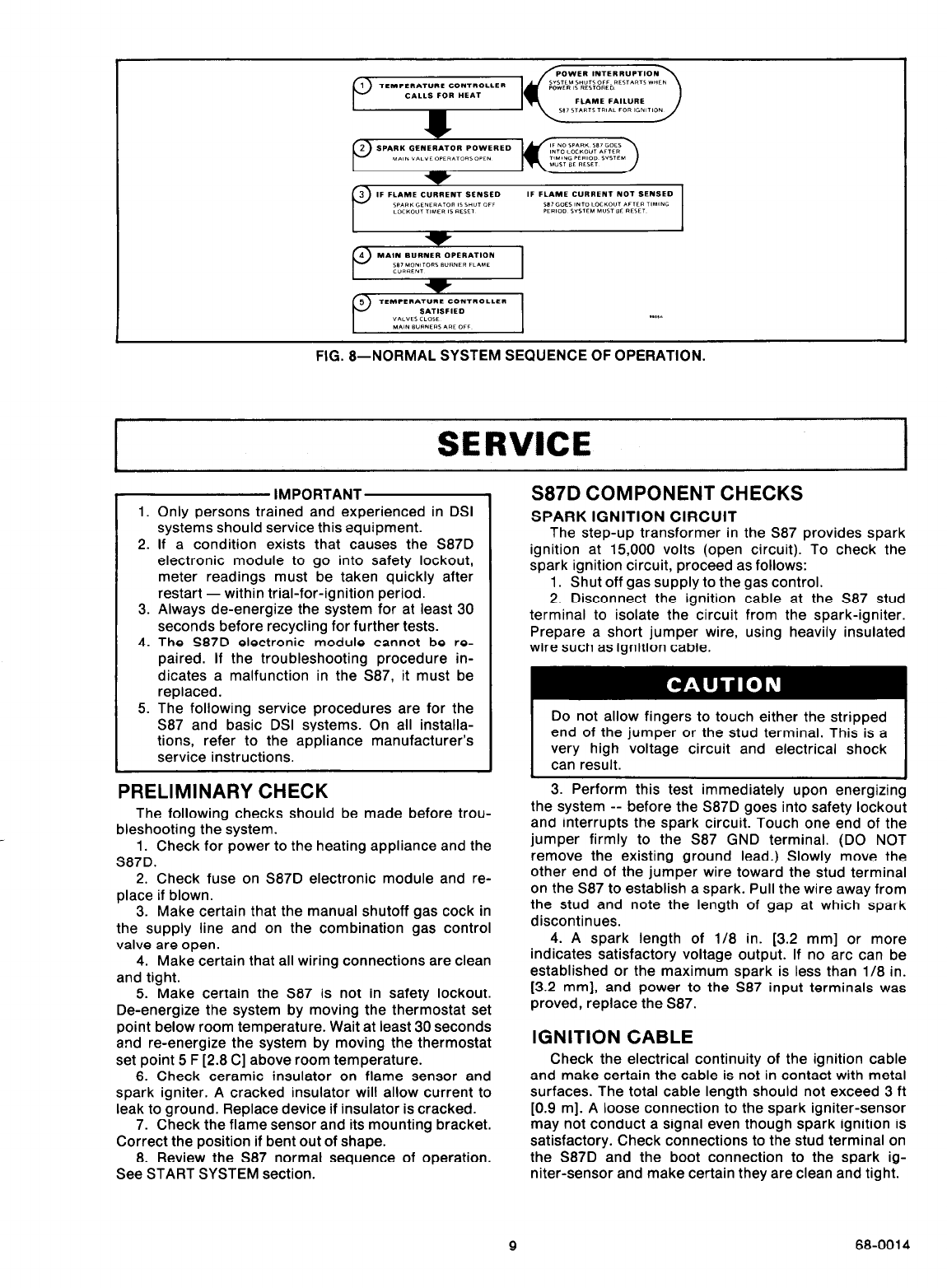

FIG. a--NORMAL SYSTEM SEQUENCE OF OPERATION.

SERVICE

l

Only persons trained and experienced in DSI

systems should service this equipment.

If a condition exists that causes the S87D

electronic module to go into safety lockout,

meter readings must be taken quickly after

restart - within trial-for-ignition period.

Always de-energize the system for at least 30

seconds before recycling for further tests.

The S87D electronic module cannot be re-

paired. If the troubleshooting procedure in-

dicates a malfunction in the S87, it must be

replaced.

The following service procedures are for the

S87 and basic DSI systems. On all installa-

tions, refer to the appliance manufacturer’s

service instructions.

1.

2.

3.

4.

5.

IMPORTANTLY

PRELIMINARY CHECK

The following checks should be made before trou-

bleshooting the system.

1. Check for power to the heating appliance and the

S87D.

2. Check fuse on S87D electronic module and re-

place if blown.

3. Make certain that the manual shutoff gas cock in

the supply line and on the combination gas control

valve are open.

4. Make certain that all wiring connections are clean

and tight.

5. Make certain the S87 is not in safety lockout.

De-energize the system by moving the thermostat set

point below room temperature. Wait at least 30 seconds

and re-energize the system by moving the thermostat

set point 5 F [2.8 C] above room temperature.

6. Check ceramic insulator on flame sensor and

spark igniter. A cracked insulator will allow current to

leak to ground. Replace device if insulator is cracked.

7. Check the flame sensor and its mounting bracket.

Correct the position if bent out of shape.

8. Review the S87 normal sequence of operation.

See START SYSTEM section.

S87D COMPONENT CHECKS

SPARK IGNITION CIRCUIT

The step-up transformer in the S87 provides spark

ignition at 15,000 volts (open circuit). To check the

spark ignition circuit, proceed as follows:

1. Shut off gas supply to the gas control.

2. Disconnect the ignition cable at the S87 stud

terminal to isolate the circuit from the spark-igniter.

Prepare a short jumper wire, using heavily insulated

wire such as ignition cable.

very high voltage circuit and electrical shock

3. Perform this test immediately upon energizing

the system -- before the S87D goes into safety lockout

and interrupts the spark circuit. Touch one end of the

jumper firmly to the 587 GND terminal. (DO NOT

remove the existing ground lead.) Slowly move the

other end of the jumper wire toward the stud terminal

on the S87 to establish a spark. Pull the wire away from

the stud and note the length of gap at which spark

discontinues.

4. A spark length of l/8 in. [3.2 mm] or more

indicates satisfactory voltage output. If no arc can be

established or the maximum spark is less than l/8 in.

[3.2 mm], and power to the S87 input terminals was

proved, replace the S87.

IGNITION CABLE

Check the electrical continuity of the ignition cable

and make certain the cable is not in contact with metal

surfaces. The total cable length should not exceed 3 ft

[0.9 m]. A loose connection to the spark igniter-sensor

may not conduct a signal even though spark ignition is

satisfactory. Check connections to the stud terminal on

the S87D and the boot connection to the spark ig-

niter-sensor and make certain they are clean and tight.

9

68-0014