GROUNDING CONNECTIONS

A common ground is required for the burner, spark

igniter-sensor mounting bracket and the GND terminal

of the 587. If ground is poor or erratic, safety shutdown

may occur occasionally even though operation is nor-

mal at time of checkout. Therefore, if nuisance shut-

downs have been reported, be sure to check ground

connections.

Electrical ground connections at the spark ig-

niter-sensor and the S87D must be clean and tight. If

leadwire is damaged or deteriorated, use only No. 14 or

No. 18 gauge, moisture-resistant, thermoplastic in-

sulated wire with 105 C [221 F] minimum rating as

replacement.

FLAME SENSOR CIRCUIT

The S87D provides ac power to the flame sensor

which the burner flame rectifies to direct current. If the

flame signal back to the S87 is not at least 1.5 uA dc, the

system will lock out.

The output of the flame sensing circuit can be

checked directly on the S87D. Check the flame sensing

circuit as follows.

1. Connect a meter (dc microammeter scale) in

series with the sensor wire as shown in Fig. 9. Use the

Honeywell Wl36A Test Meter or equivalent. Disconnect

the sensor wire at the S87D. Connect the red (positive)

lead of the meter to the free end of the sensor wire.

Connect the black (negative) meter lead to the sensor

terminal on the S87.

2. Restart the system and read the meter. The flame

sensor current must be at least 1.5uA and steady. If the

reading is less than 1.5 uA or unsteady, see LOW OR

UNSTEADY FLAME CURRENT section, below.

FLAME SENSOR CURRENT CHECK-USE YA SCALE

FIG. g-S87 FLAME CURRENT MEASUREMENT.

LOW OR UNSTEADY FLAME CURRENT

If the current to the S87D flame circuit is less than 1.5

AIA or is unsteady, check the burner flame and flame

sensor location and electrical connections as follows.

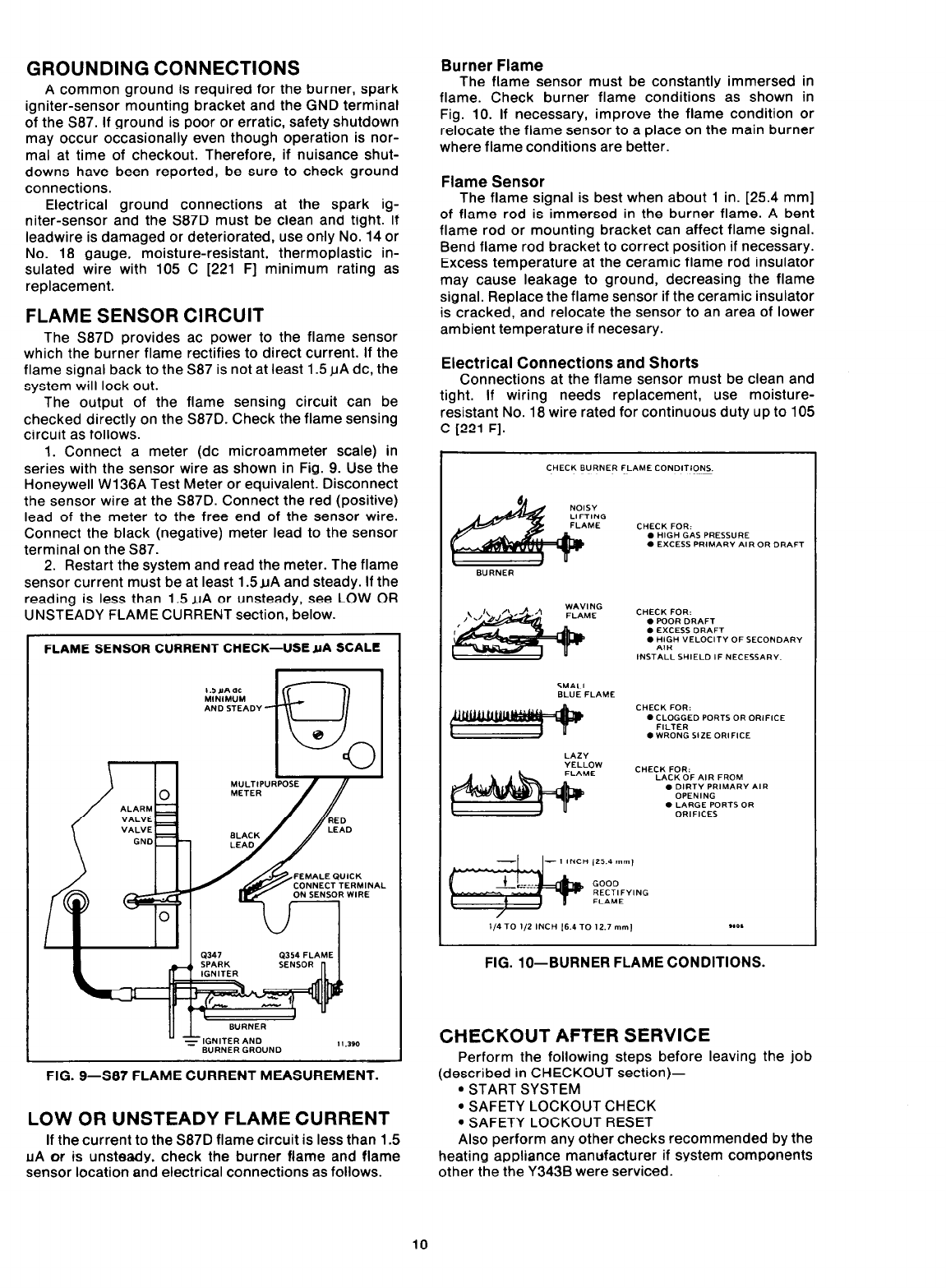

Burner Flame

The flame sensor must be constantly immersed in

flame. Check burner flame conditions as shown in

Fig. 10. If necessary, improve the flame condition or

relocate the flame sensor to a place on the main burner

where flame conditions are better.

Flame Sensor

The flame signal is best when about 1 in. [25.4 mm]

of flame rod is immersed in the burner flame. A bent

flame rod or mounting bracket can affect flame signal.

Bend flame rod bracket to correct position if necessary.

Excess temperature at the ceramic flame rod insulator

may cause leakage to ground, decreasing the flame

signal. Replace the flame sensor if the ceramic insulator

is cracked, and relocate the sensor to an area of lower

ambient temperature if necesary.

Electrical Connections and Shorts

Connections at the flame sensor must be clean and

tight. If wiring needs replacement, use moisture-

resistant No. 18 wire rated for continuous dutv up to 105

_

C [221 F].

FIG. lo--BURNER FLAME CONDITIONS.

CHECKOUT AFTER SERVICE

Perform the following steps before leaving the job

(described in CHECKOUT section)-

* START SYSTEM

l SAFETY LOCKOUT CHECK

. SAFETY LOCKOUT RESET

Also perform any other checks recommended by the

heating appliance manufacturer if system components

other the the Y343B were serviced.

10