Position the Q347 so that only the tips of the elec-

trodes are immersed in the burner flame. The burner

must ignite smoothly - usually this will be ac-

complished with tip of electrodes (spark gap) spaced

approximately l/4 in. [6.4 mm] from the surface of the

burner. Gas must flow into one of the three open sides

of the spark gap (where outer electrode does not block

gas). The center electrode must not be near any

ground.

The spark gap is factory-adjusted to 5/32 in. [4 mm].

If this setting is disturbed in shipment or installation,

readjust by carefully bending the bent tip of the ground

(outer) electrode only.

Q354A FLAME SENSOR

The Q354 should be rigidly mounted in an accessible

location. It must remain in a fixed position relative to the

main burner. Mount the Q354 on a separate bracket or

on the same bracket with the Q347 Spark Igniter.

Tip of rod must be immersed in main burner flame.

Depth of immersion (usually about 1 in. [25.4 mm]) and

distance from rod to burner surface (usually l/4 in. [6.4

mm]) depends on type of burner and flame configura-

tion. Position selected must produce sensor current of

1.5 microamperes (minimum). See Fig. 9, Page 10, to

measure current.

The main burner serves as the grounding area for

the flame signal. Install ground wire from the main

burner to the ground terminal of the S87D.

AUXILIARY CONTROLS

1. If a common transformer is used to power both

the S87D and the burner valve circuit, its

capacity (VA) must be adequate for all of the

system components (see Table 2).

2. Turn off gas supply before beginning installa-

tion. After installing gas control, be sure to

conduct Gas Leak Test, page 8.

Install the auxiliary controls required in the complete

control system, following the instructions of the ap-

pliance or control manufacturer.

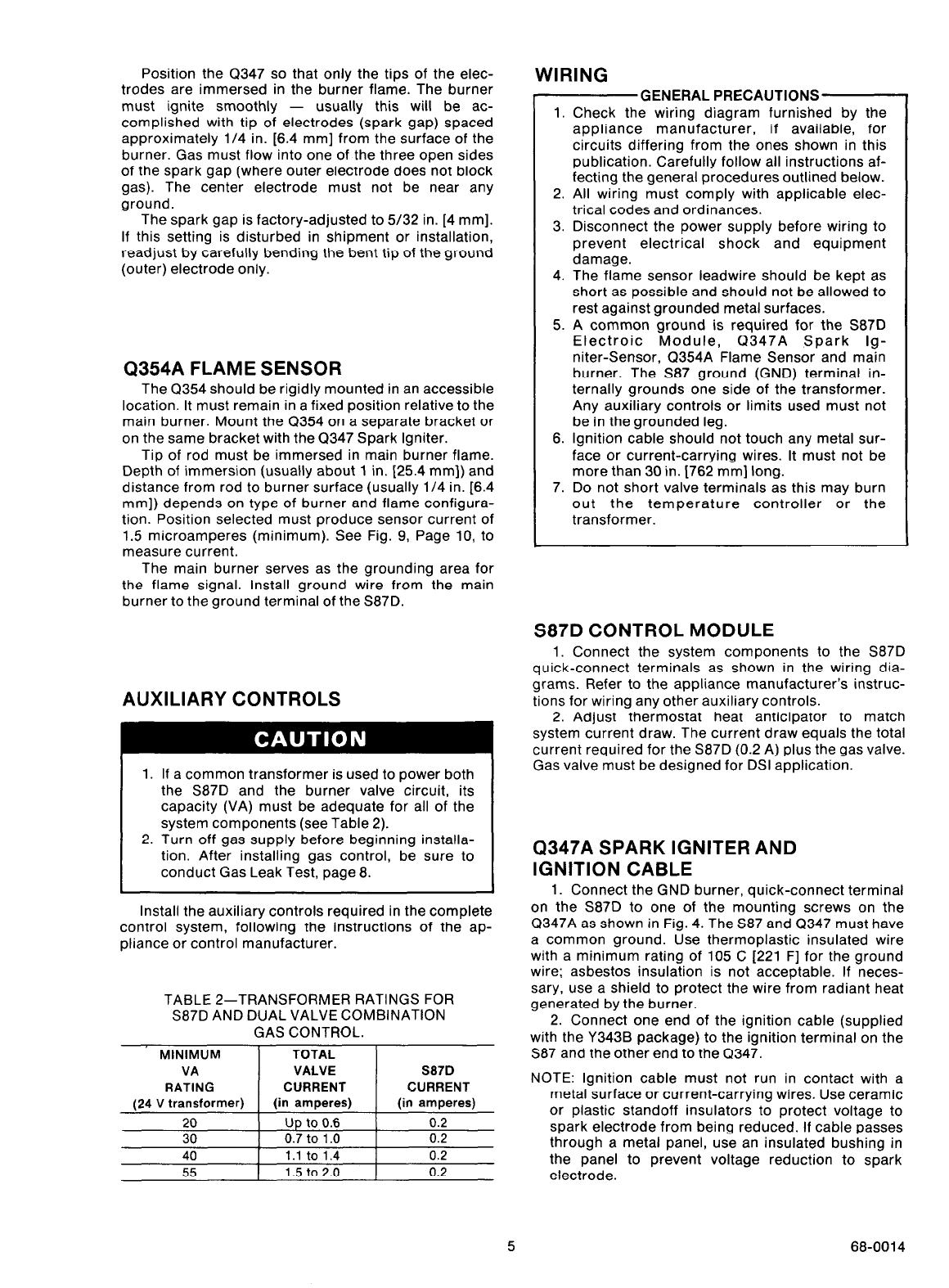

TABLE 2-TRANSFORMER RATINGS FOR

S87D AND DUAL VALVE COMBINATION

GAS CONTROL.

MINIMUM

TOTAL

VA

VALVE

RATING

CURRENT

(24 V transformer)

(in amperes)

S87D

CURRENT

(in amperes)

20 Up to 0.6 0.2

30 0.7 to 1 .o 0.2

40 1.1 to 1.4 0.2

55 1.5 to 2.0 0.2

WIRING

GENERAL PRECAUTIONS’-f

1.

2.

3.

4.

5.

6.

7.

Check the wiring diagram furnished by the

appliance manufacturer, if available, for

circuits differing from the ones shown in this

publication. Carefully follow all instructions af-

fecting the general procedures outlined below.

All wiring must comply with applicable elec-

trical codes and ordinances.

Disconnect the power supply before wiring to

prevent electrical shock and equipment

damage.

The flame sensor leadwire should be kept as

short as possible and should not be allowed to

rest against grounded metal surfaces.

A common ground is required for the S87D

Electroic Module, Q347A Spark lg-

niter-Sensor, Q354A Flame Sensor and main

burner. The S87 ground (GND) terminal in-

ternally grounds one side of the transformer.

Any auxiliary controls or limits used must not

be in the grounded leg.

Ignition cable should not touch any metal sur-

face or current-carrying wires. It must not be

more than 30 in. 1762 mm] long.

Do not short valve terminals as this may burn

out the temperature controller or the

transformer.

S87D CONTROL MODULE

1. Connect the system components to the S87D

quick-connect terminals as shown in the wiring dia-

grams. Refer to the appliance manufacturer’s instruc-

tions for wiring any other auxiliary controls.

2. Adjust thermostat heat anticipator to match

system current draw. The current draw equals the total

current required for the S87D (0.2 A) plus the gas valve.

Gas valve must be designed for DSI application.

Q347A SPARK IGNITER AND

IGNITION CABLE

1. Connect the GND burner, quick-connect terminal

on the S87D to one of the mounting screws on the

Q347A as shown in Fig. 4. The S87 and Q347 must have

a common ground. Use thermoplastic insulated wire

with a minimum rating of 105 C [221 F] for the ground

wire; asbestos insulation is not acceptable. If neces-

sary, use a shield to protect the wire from radiant heat

generated by the burner.

2. Connect one end of the ignition cable (supplied

with the Y343B package) to the ignition terminal on the

S87 and the other end to the Q347.

NOTE: Ignition cable must not run in contact with a

metal surface or current-carrying wires. Use ceramic

or plastic standoff insulators to protect voltage to

spark electrode from being reduced. If cable passes

through a metal panel, use an insulated bushing in

the panel to prevent voltage reduction to spark

electrode.

5

68-0014