T7351 COMMERCIAL PROGRAMMABLE THERMOSTAT

15 63-2666—03

— Recovery ramping applies between scheduled

heat or cool setpoint changes from not occupied to

standby and not occupied to occupied.

— Other setpoint changes use a setpoint step

change.

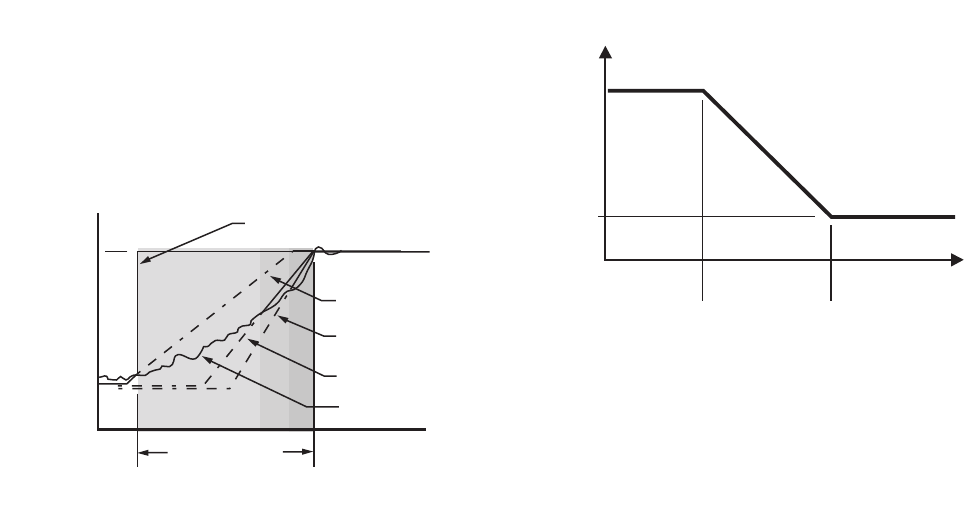

Recovery Ramping for Heat Pump

Systems

During recovery with heat pump equipment, the heating

setpoint is split into a heat pump setpoint for compressors, and

two auxiliary heat setpoints for the auxiliary heat stages. (Refer

to Fig. 11 for the various setpoints.)

Fig. 11. Heat Setpoint Ramping for Heat Pump Systems.

Heat pump ramping for heating proceeds as

follows:

1. The heat pump setpoint begins to ramp until the room

temperature and the compressor ramp intersect.

2. At this point, the heat pump setpoint performs a step

change to the Occupied (or Standby) setpoint and all

auxiliary heat stages are disabled.

NOTE: The heat pump setpoint remains here for the

rest of the Not Occupied period.

3. The stage one auxiliary heat ramp is calculated based

on a steeper slope starting 1° F (0.5° C) below the not

occupied setpoint.

4. When the room temperature intersects this auxiliary heat

ramp, the first stage of auxiliary heat is enabled.

5. The stage two auxiliary heat ramp is calculated based on

an even steeper slope starting 2° F (1° C) below the not

occupied setpoint.

6. When the room temperature intersects this auxiliary heat

ramp, the second stage of auxiliary heat is enabled.

During the cool recovery period, the setpoint changes at a rate

in degrees per hour relative to the outdoor air temperature. If

there is no outdoor air temperature sensor available, the

minimum ramp rate is used.

See Fig. 12 for the various setpoints.

NOTE: For cooling, the same method is used in both

conventional and heat pump systems.

NOTE: The setpoint used during the cool recovery period

is similar to the heat mode in Fig. 10, except the

slope of the line reverses for cooling.

Fig. 12. Setpoint Ramping Parameters with Ramp Rate

Calculation.

Advantages:

• Comfort setting is achieved at the programmed time and

maintained regardless of weather conditions; occupants are

comfortable.

• Drafts from low-temperature discharge air are minimized

during Occupied periods.

• Use of the more economical first stage of heat is maximized

during recovery, minimizing use of the expensive later heat

stage(s).

• Comfort and energy savings can be achieved in both

heating and cooling.

• Heat cycling reduced, extending equipment life.

Auxiliary Relay

The auxiliary relay can be used with a variety of controls:

• Time-of-day (TOD).

• Economizer minimum position control.

• Dehumidification (see Dehumidification section).

Relay for Time-Of-Day (Table 8)

Time-of-day (TOD) is the Auxiliary Relay default configuration.

TOD logic operates strictly according to programming:

— Occupied: Relay contacts closed.

— Not Occupied: Relay contacts open.

— Standby (Scheduled): Relay contacts closed.

Relay for Economizers

Mechanical cooling is often used with outside temperatures in

the 50° F (10° C) to 60° F (16° C) range and humidity below 50

percent. In central and northern climates, hundreds of hours

fall into this temperature category. By permitting 80 to 100

percent outside air into the system, mechanical cooling may

not be needed at all, particularly during Spring and Fall.

Economizers take advantage of outside air. The typical

economizer consists of an outside air damper, motor, outdoor

air changeover control and a minimum position potentiometer.

The motor controls the dampers. Suitability of the outside air

for cooling is determined by the outdoor air changeover control.

AUX HEAT

STAGE 1 RAMP

NORMAL

RECOVERY RAMP

OCCUPIED

SETPOINT

NOT OCCUPIED

SETPOINT

M19877

RECOVERY TIME

OCCUPIED

TIME

AUX HEAT

STAGE 2 RAMP

HEAT PUMP SETPOINT

(FOR COMPRESSORS)

SPACE

TEMPERATURE

COOL RECOVERY

RAMP RATE

(DEGREES/HOUR)

MaxClRamp

MinClRamp

OaTempMinClRamp OaTempMaxClRamp

OUTDOOR AIR

TEMPERATURE

M10111A