FP USER INSTRUCTIONS ENGLISH 71576286 - 07/06

Page 24 of 35

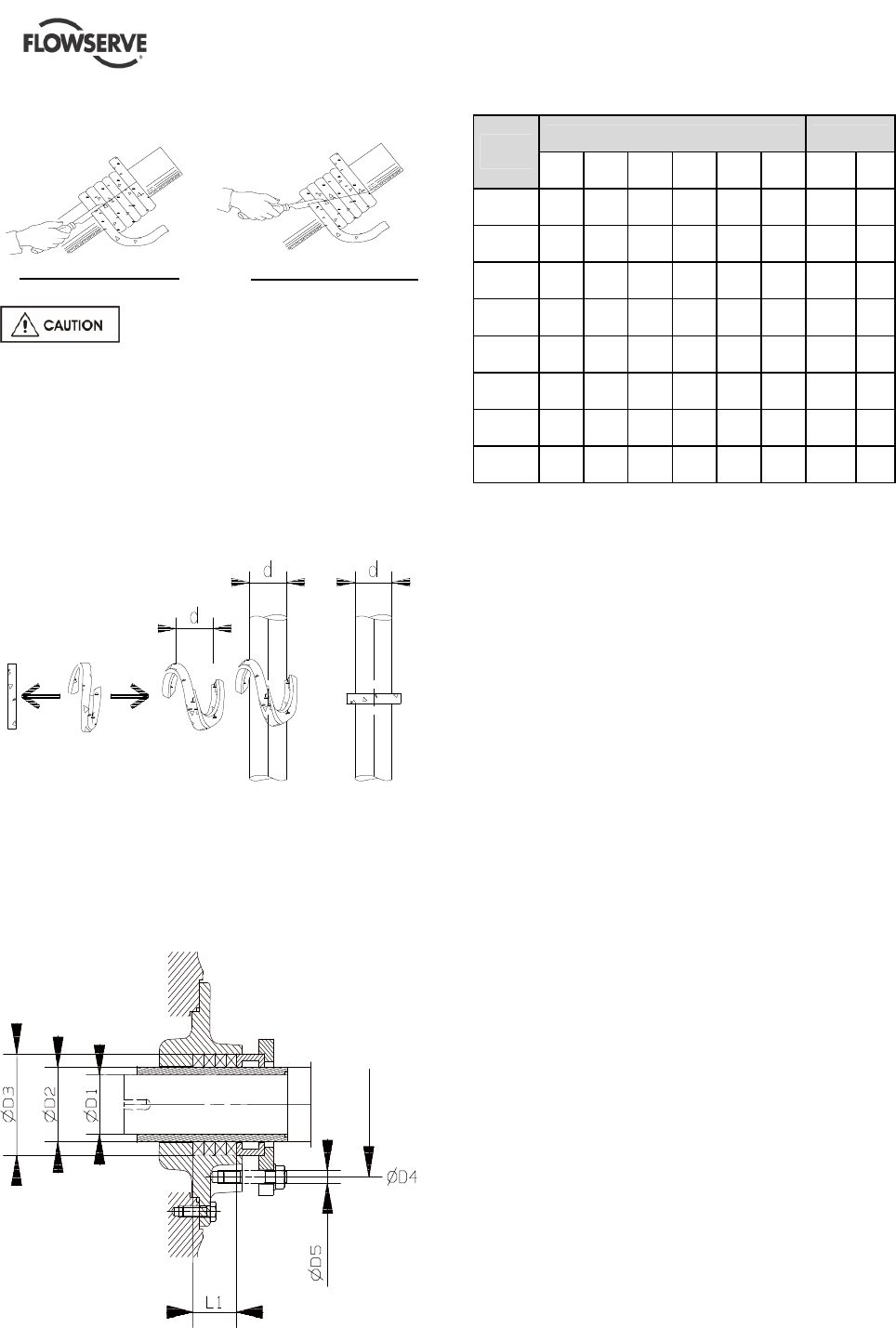

Example of straight Example of bevel cut

Ensure a tightening on the stuffing

box housing and not on the sleeve.

SETTING OF PACKING

Follow the instructions:

a) Assemble of the packing in S.

b) Stagger by about 90° between two rings.

c) Assemble packing after packing.

After setting the last packing ring, secure the

packing with the gland and tighten the nut by hand.

After tightening, the shaft should turn by hand as

easily as before the setting of the packing.

DIMENSIONS IN MILLIMETERS PACKING

PUMP

TYPE

D1 D2 D3 D4 D5 L1 Lgth

50 FP 24 30 46 70 M10 48 600 8

65 FP 24 30 46 70 M10 48 600 8

80 FP 32 40 60 86 M12 63 800 10

100 FP 32 40 60 86 M12 63 800 10

122 FP 45 55 75 100 M12 45 850 10

125 FP 40 50 70 96 M12 60 1000 10

152 FP 55 70 95 135 M12 78 1100 12

202 FP 65 80 109 150 M16 91 1200 14

For arrangement of packing, see section 8.1,

Sectional drawings.

6.2.6 Internal coating

If the pump has an internal coating, this coating

must be inspected periodically. Any wear or cracks

of the coating found must be immediately repaired.

Failure to do this may lead to accelerated wear of

the coating during operation and corrosion of the

exposed base metal, depending on the material and

pumped liquid. Special attention must be paid to the

coating edges. Any loss of coating material is

considered to be normal wear and tear on the pump

and is not considered as warranty. Flowserve has

applied the coatings according to the supplier's

instructions but will not be held responsible for

coating wear or cracks that may develop over time.

6.3 Spare parts

6.3.1 Ordering of spares

Flowserve keeps records of all pumps that have

been supplied. When ordering spares the following

information should be quoted:

1) Pump serial number.

2) Pump size.

3) Part name

4) Part number

5) Number of parts required.

The pump size and serial number are shown on the

pump nameplate.

To ensure continued satisfactory operation,

replacement parts to the original design specification

should be obtained from Flowserve. Any change to

the original design specification (modification or use

of a non-standard part) will invalidate the pump’s

safety certification.