FP USER INSTRUCTIONS ENGLISH 71576286 - 07/06

Page 15 of 35

If necessary, improve the machine alignment:

Complete unit mounted on common base plate:

The machines are first aligned accurately in our

workshops. Usually, any misalignment observed on-

site is due to a wrong adjustment under the base

plate (disturbed during transport or because of

forces exerted by the pipework). It is only necessary

to rectify the adjustment under base plate. If it

proves to be insufficient, modify the motor and the

pipeworks adjustment.

Pump and motor mounted on individual base

plates:

Machines are (or must be) first mounted on their

own base plate in the workshop. Once the pump is

set, it will be regarded as the fixed piece. Any

alignment necessary shall be carried out on the

motor.

Never connect the electric motor

before the setting has been completely finished.

4.5 Piping

The user must verify that the equipment is

isolated from any external sources of vibration.

Protective covers are fitted to the

pipe connections to prevent foreign bodies entering

during transportation and installation. Ensure that

these covers are removed from the pump before

connecting any pipes.

4.5.1 Suction and discharge pipework

The dimensions of the pipes do not directly depend

on suction and discharge diameters of the pump.

a) First, choose a flow speed < 2 m/s at suction,

and about 3 m/s at discharge.

b) Take into account the available NPSH, which

must be superior to the required NPSH of the

pump.

Never use pump as a support for

piping.

Do not mount expansion joints in

such a way that their force, due to internal pressure,

may act on the pump flange.

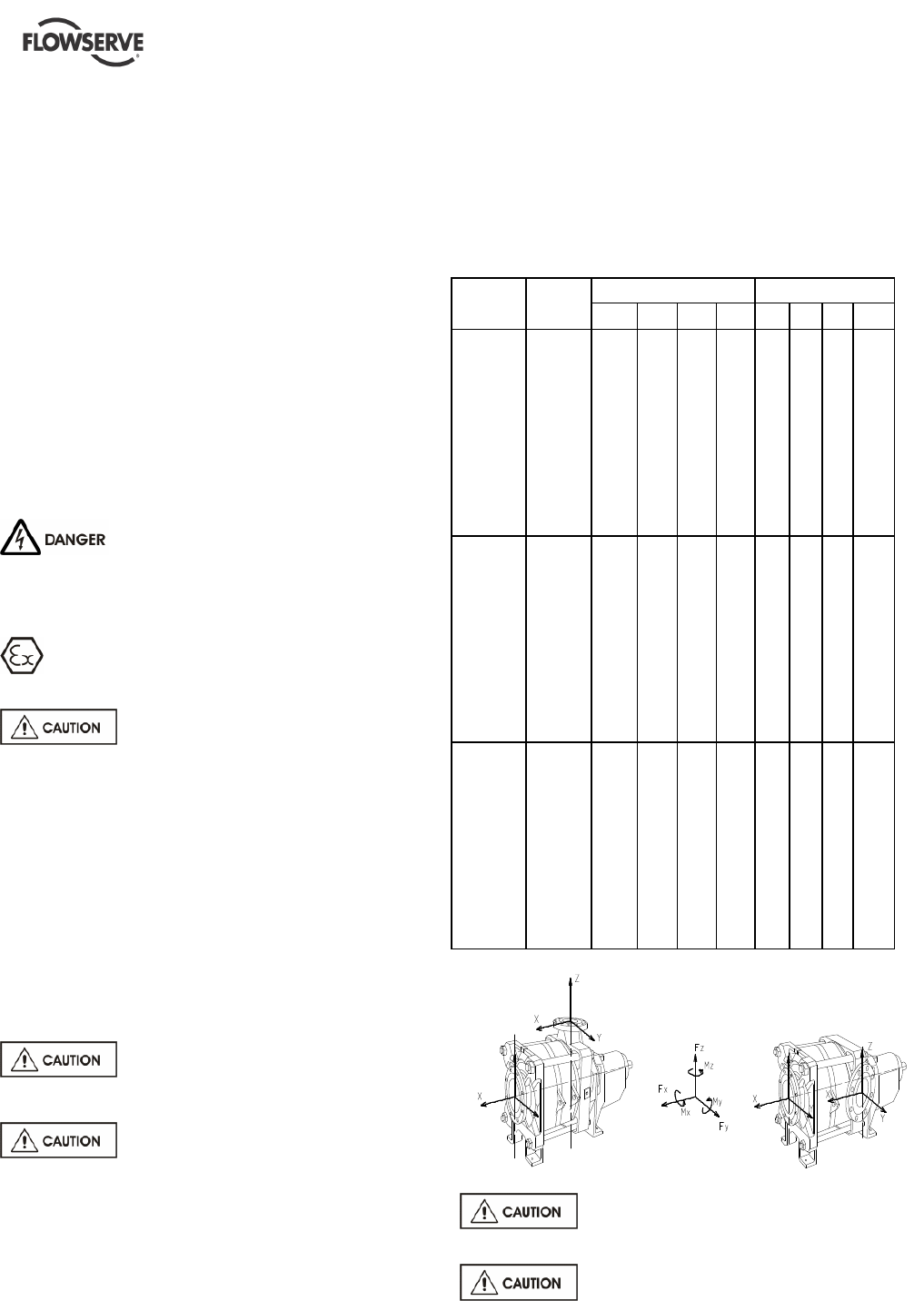

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. These

external strains may cause misalignment, hot

bearings, worn couplings, vibrations and the

possible failure of the pump casing.

When designing the pipes (§ 4.5.2.1, § 4.5.2.2, §

4.5.3.1) take necessary precautions in order not to

exceed maximum allowed strains.

Forces and moments applied to the pump flanges

must never exceed the values shown in the table

below:

DN

Forces (daN) Moments (daN.m)

Pipe

Layout flanges

F

Y

F

Z

F

X F

M

Y

M

Z

M

X M

40 30 40 35 60 23 27 34 49

50 40 50 45 80 27 30 37 54

65 50 68 58 102 30 33 40 60

80 60 75 70 120 32 36 44 65

100 80 100 90 160 36 41 50 74

125 100 125 110 200 44 52 63 92

150 120 150 135 240 53 62 75 110

Vertical pipe

perpendicular to the shaft

200 162 200 180 314 69 79 97 144

40 40 30 35 60 23 27 34 49

50 50 40 45 80 27 30 37 54

65 68 50 58 102 30 33 40 60

80 75 60 70 120 32 36 44 65

100 100 80 90 160 36 41 50 74

125 125 100 110 200 44 52 63 92

150 150 120 135 240 53 62 75 110

Horizontal pipe

perpendicular to the shaft

200 200 162 180 314 69 79 97 144

40 35 30 40 60 23 27 34 49

50 45 40 50 80 27 30 37 54

65 58 50 68 102 30 33 40 60

80 70 60 75 120 32 36 44 65

100 90 80 100 160 36 41 50 74

125 110 100 125 200 44 52 63 92

150 135 120 150 240 53 62 75 110

Pipe parallel to the axis

200 180 162 200 314 69 79 97 144

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is

arranged to allow pump flushing before removal of

the pump.