HEAT CONTROLLER, INC. WATER-SOURCE HEAT PUMPS

Residential Split - 60Hz R410A

Rev.: 03 August, 2012

Heat Controller, Inc. Water-Source Heating and Cooling Systems22

HWG Water Piping

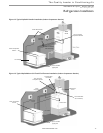

1. Using at least 1/2” [12.7mm] I.D. copper, route and

install the water piping and valves as shown in Figures

15 or 16. Install an approved anti-scald valve if the 150°F

HWG setpoint is or will be selected. An appropriate

method must be employed to purge air from the HWG

piping. This may be accomplished by fl ushing water

through the HWG (as in Figures 15 and 16) or by

installing an air vent at the high point of the HWG piping

system.

2. Insulate all HWG water piping with no less than 3/8”

[10mm] wall closed cell insulation.

3. Open both shut off valves and make sure the tank drain

valve is closed.

Water Tank Refi ll

1. Close valve #4. Ensure that the HWG valves (valves #2

and #3) are open. Open the cold water supply (valve #1)

to fi ll the tank through the HWG piping. This will purge air

from the HWG piping.

2. Open a hot water faucet to vent air from the system until

water fl ows from faucet; turn off faucet. Open valve #4.

3.

Depress the hot water tank pressure relief valve handle to

ensure that there is no air remaining in the tank.

4. Inspect all work for leaks.

5.

Before restoring power or fuel supply to the water heater,

adjust the temperature setting on the tank thermostat(s)

to insure maximum utilization of the heat available from

the refrigeration system and conserve the most energy.

On tanks with both upper and lower elements and

thermostats, the lower element should be turned down

to 100°F [38°C] or the lowest setting; the upper element

should be adjusted to 120-130°F [49-54°C]. Depending

upon the specifi c needs of the customer, you may want

to adjust the upper element differently. On tanks with a

single thermostat, a preheat tank should be used (Fig 16).

6. Replace access cover(s) and restore power or

fuel supply.

Initial Start-Up

1. Make sure all valves in the HWG water circuit are

fully open.

2. Turn on the heat pump and allow it to run for

10-15 minutes.

3. Set S3-4 to the “ON” position (enabled) to engage the

HWG.

4. The HWG pump should not run if the compressor is not

running.

5. The temperature difference between the water entering

and leaving the HWG coil should be approximately

5-10°F [3-6°C].

6. Allow the unit to operate for 20 to 30 minutes to insure

that it is functioning properly.

Table 6: HWG Water Piping Sizes and Length

Unit

Nominal

Tonnage

Nominal

HWG Flow

(gpm)

1/2" Copper

(max length*)

3/4" Copper

(max length*)

2.0 0.8 50 -

3.0 1.2 50 -

4.0 1.6 45 50

5.0 2.0 25 50

*Maximum length is equivalent length (in feet) one way of type L

copper.

Hot Water Generator

WARNING!

WARNING! The HWG module is an appliance that operates

in conjunction with the heat pump system, the hot water

system and the electrical system. Installation should only be

performed by skilled technicians with appropriate training

and experience. The installation must be in compliance with

local codes and ordinances. Local plumbing and electrical

building codes take precedence over instructions contained

herein. The Manufacturer accepts no liability for equipment

damaged and/or personal injury arising from improper

installation of the HWG module.

CAUTION!

CAUTION! Locate Refrigerant lines to avoid accidental

damage by lawnmowers or children.

NOTICE! Make sure the compressor discharge line is

connected to the “Hot Gas In” stub on the Heat Recovery Unit.