20

When wood is burned slowly, it produces tar

and other organic vapors, as well as soot, which

combine with expelled moisture to form creosote.

The creosote vapors condense in the relatively

cool chimney ue (associated with a slow burning

re). As a result, creosote accumulates on the ue

lining. When ignited, this creosote can result in an

extremely hot re.

The FireDome on the TL300 cuts creosote to

almost nothing

The chimney should be inspected at least once

every two months during the heating season to see if

any creosote build-up has occurred. Checking your

chimney and chimney connector more frequently,

especially while you are getting used to your stove,

is recommended. To inspect this system, let the

stove cool. Using a ashlight and mirror, check the

interior of the chimney connector, and the chimney

itself. If a signicant layer of creosote or soot has

accumulated (1/8" or 3 mm) it should be removed

to reduce the risk of a chimney re.

To clean deposits from the surface of the

connector, use a stiff wire brush after dismantling

the connector assembly. To clean the chimney,

use a specially designed brush sized to t your

particular flue opening, or call an established

chimney cleaning service.

At the end of the heating season, perform a

thorough examination of your chimney system, and

have it repaired if necessary.

After the stove has been in operation for awhile,

the damper gasket may compress and allow the

damper handle to move from the open to the closed

position without the added ramp tension needed

to keep the damper held in the closed position.

• After the stove has cooled off, remove the stove

pipe from the stove collar and close the damper.

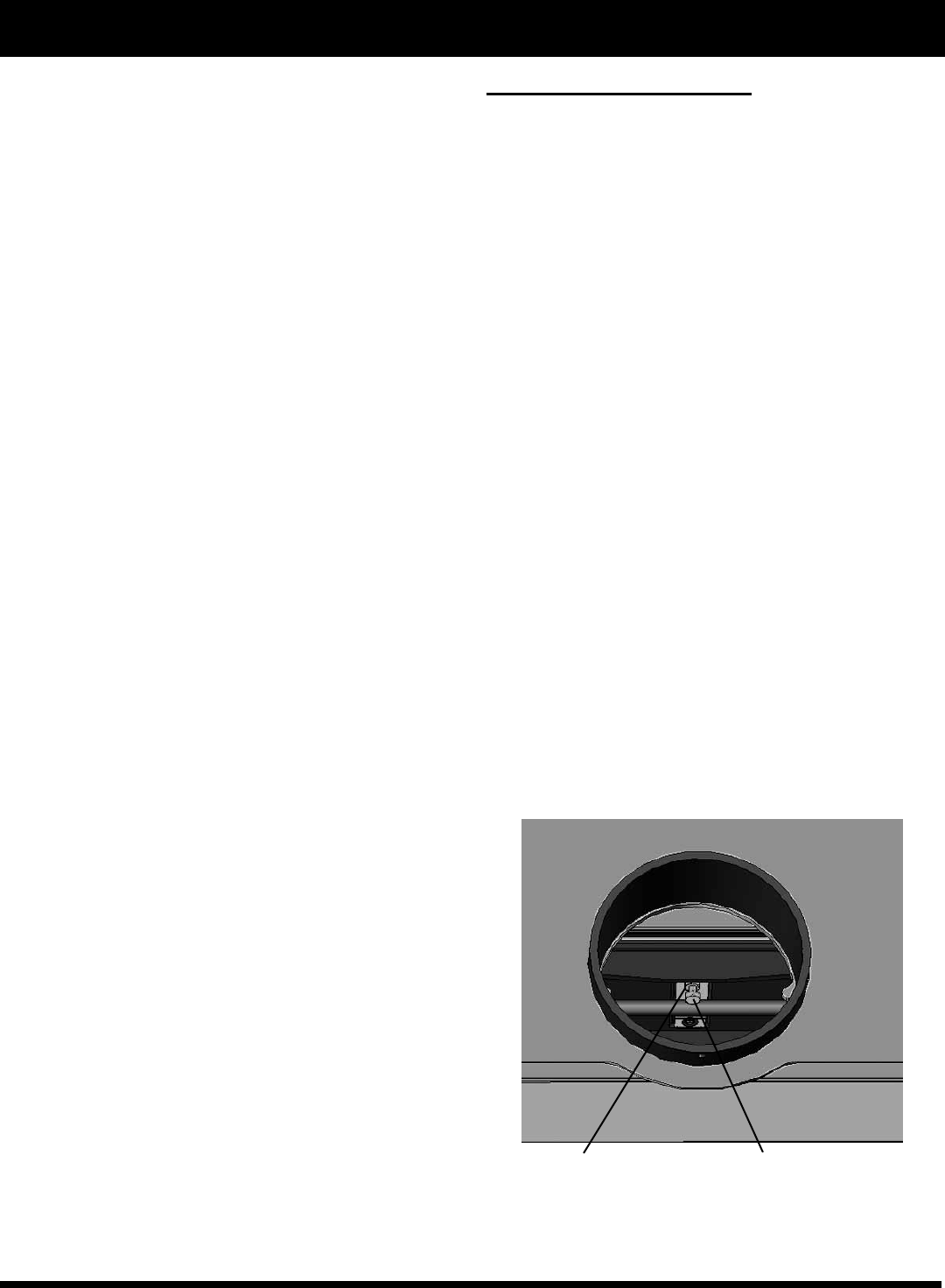

• Using a ashlight, look into the collar. About

midpoint of the damper plate on the backside you

will see the adjustment bolt for the ramp tension.

(See gure on right.)

• You will need (2) 7/16 " wrenches. Use one to hold

the bolt still while using the other to loosen the nut.

• Turn the bolt inward (clockwise facing the head)

approximately 1/4 turn and retighten the locknut.

• Now open and close the damper to check for

proper tension on the damper lever while moving

into the closed direction.

• If the tension is incorrect, readjust the bolt.

Gaskets are used at strategic positions when

building the Harman TL300 for controlling the

path that incoming and outgoing air and gases

take through the stove. You must check these

gaskets from time to time and replace them when

necessary. The gaskets are made of berglass

of different sizes (obtainable from your Harman

dealer) and some are xed in place with a high

temperature stove gasket cement. To change a

gasket, rst remove the worn berglass and clean

the area with a wire brush. Also clean any other

surfaces that come into contact with the gasket.

Place a small bead of cement in the area under the

gasket if required, then press new gasket material

into the channel; do not overlap the ends. Seat the

gasket rmly by applying pressure when possible;

for example, after changing the door gasket, close

the door. Allow the cement to dry before using

your stove.

Gaskets are located:

• On the doors to provide airtight closure.

• Between the damper and the damper frame.

• Rear cover

• Rear housing

Loosen nut

Turn bolt inward 1/4

turn.