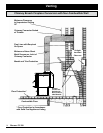

Combustion in the Harman TL300 is precisely

controlled and is divided into two parts.

During combustion, primary air enters at the

bottom front of the stove and travels up channels

at either side of the front door. This pre-heated air

then enters the manifold, located above the front

door, where it is released into the rebox as a sheet

of air between the glass and the re. This air-wash

system cleans the glass as it provides oxygen to

the rebox.

Secondary combustion air enters the stove at the

bottom rear of the stove. Here, in the "Firedome", it

mixes additional oxygen with the exhaust, causing

it to be re-burned. This secondary combustion

is necessary to achieve and sustain long, clean

burning.

During combustion, the burning of wood proceeds

through several stages. The initial or evaporation

stage is where the moisture in the wood is driven off

in the form of steam. During the second stage, the

volatile gases contained in the wood are released

and burned. This represents most of the wood's

heating capacity. The nal stage is the charcoal

stage where the charcoal burns the remaining

heat content out of the fuel. Ash remains after the

burning is complete. Within the primary rebox,

two or more of these stages of combustion are

occurring simultaneously.

Two important controls - the top load door handle

and the air control lever regulate the operation and

output of the stove.

The top loading door handle is linked to the bypass

damper and serves two purposes. Move the handle

forward one position (approximately 3") and the

handle automatically opens the bypass damper,

you must open the bypass damper, or smoke will

come into the room. In this mode of operation

the combustion gases go directly from the main

combustion chamber to the ue collar and exit into

the chimney.

Continue moving and lifting the handle and it

opens the top loading door.

Open the bypass damper

by pulling the handle toward the front of the stove.

Damper Open

Damper Closed