Temperature & Pressure Relief Valve

For protection against excessive pressure and/or tempera-

tures, a temperature and pressure relief valve has been

installed in the water heater.

ANY REPLACEMENT VALVE MUST NOT EXCEED THE

TEMPERATURE AND PRESSURE RATING. FAILURE TO

INSTALL AND MAINTAIN A NEW, PROPERLY LISTED

TEMPERATURE AND PRESSURE RELIEF VALVE WILL

RELEASE THE MANUFACTURER FROM ANY CLAIMS

WHICH MIGHT RESULT FROM EXCESSIVE TEMPERA-

TURE OR WATER PRESSURE.

Pressure rating of the valve must not exceed the working

pressure shown on the rating plate of the water heater. The

discharge capacity must be equal to or greater than the

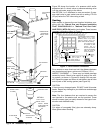

input to the water heater. Temperature and Pressure Relief

valve piping must terminate 152mm (6 in.), no more than

305mm (12 in.) (reference the applicable code) above a

floor drain or external to the building. Do not thread, cap, or

plug the end of this discharge line. Be certain that no con-

tact is made with any live electrical part. Do not connect dis-

charge line directly to drain (see Figure 2A). To prevent bod-

ily injury, hazard to life or damage to property, the relief

valve must be allowed to discharge water in the event of

excessive temperature or pressure developing in the water

heater. The function of the temperature and pressure relief

valve is to discharge water in quantities should circum-

stances demand. If the discharge pipe is not directed to

drain as shown in Figure 2A, or other suitable means, the

water flow may cause property damage.

The discharge line:

1. must not be smaller than the outlet pipe size of the relief

valve,

2. must not be plugged or blocked,

3. must be material capable of withstanding 99°C (210°F)

without distortion,

4. must be installed so as to allow complete drainage of

both temperature and pressure relief valve,

5. must terminate at an adequate drain, and

6. must not have any valve between the relief valve and

the water heater.

Closed system/Thermal expansion

Periodic discharge of the temperature and pressure relief

valve may be due to thermal expansion in a closed water

supply system. The water utility supply meter may contain a

check valve, backflow preventer or water pressure-reducing

valve. This will create a closed water system. During the

heating cycle of the water heater, the water expands caus-

ing pressure inside the water heater to increase. This may

cause the temperature and pressure relief valve to dis-

charge small quantities of hot water. To prevent this, it is

recommended that a diaphragm-type expansion tank (suit-

able for potable water) be installed on the cold water supply

line. The expansion tank must have a minimum capacity of

5.6 litres (1.5 US gallons) for every 190 litres (50 US gal-

lons) of stored water and be rated at the working pressure

of the water heater. Contact the local water supplier or

plumbing inspector for information on other methods to con-

trol this situation.

Important: Do not plug or remove the temperature and

pressure relief valve.

Installation Checklist

WARNING

Do not attempt to operate this water heater

with the cold water inlet valve closed.

Manually operate the Temperature and

Pressure Relief valve at least once a year.

Standing clear of the outlet (discharge water

may be hot), lift and release the lever handle

on the Temperature and Pressure Relief

valve to make the valve operate freely.

NEVER OPERATE THE HEATER IF IT IS NOT

COMPLETELY FILLED WITH WATER. TO

MAKE SURE THE HEATER IS FILLED, OPEN

A HOT WATER TAP UNTIL A FULL FLOW OF

WATER IS VISIBLE WITH NO AIR ESCAPING.

Check Here

1. Have the vent location limitations and minimum

height for vent termination and maximum vent

length been checked?

2. Are the terminal and vent pipes installed and

sealed properly?

3. Has the gas piping been leak tested?

4. Is there 508mm (20 in.) at the top and 25mm (1

in.) around the vent pipe?

5. Have you taken steps to prevent water damage

in case of leaks?

6. Is the diptube installed in the cold water inlet

connection?

7. Is the water heater completely filled with

water?

8. Does the gas piping conform with the recom-

mendations of your Local Gas Utility

Company?

9. Is the vent terminal opening unobstructed?

10. Is a temperature and pressure relief valve

installed?

11. Is the drain pipe from the T&P valve unob-

structed?

12. Has all plastic and cardboard packaging mate-

rial been removed from the heater and vent-

ing?

If the answer to all of the questions above is

“Yes”, read the Operating Instructions and

proceed with lighting the heater.

– 10 –