Venting instructions

1. Plan the venting layout starting at the vent termination

and work back toward the heater. Take into considera-

tion the style and position of the vent termination, the

vent pipe routing, elbows and connectors required and

the necessary support hangers.

2. G/JW 40, 50 and 60-gallon heaters may use 50mm (2

in.) or 76mm (3 in.) venting depending on "Equivalent

Vent Length" as described in Table 2. G/JW5065 high

input models require 76mm (3 in.) venting. See also the

section on "Vent pipe connection to blower".

3. Venting should be as direct as possible with the fewest

number of fittings. Use long radius 45 degree and long

radius 90 degree elbows wherever possible.

4. Do not use 90 degree elbows "back to back" (other than

termination installations) and do not use street elbows.

Maintain a minimum 150mm (6 in.) straight section

between elbows. Closely coupled and short radius

elbows reduce the venting capacity (see Figure 6 and

the note below it).

5. DO NOT USE AN ELBOW AS A SUPPORT POINT.

Elbows are not designed to carry the weight of the vent-

ing system.

6. Calculate "Equivalent Vent Length" before starting. Do

not exceed the values shown in Table 2. An example of

how this length is determined is shown in Figure 8. The

value from your calculations should also be used to

determine which rodent screen to install into the vent

termination elbow.

7. Measure the vent piping and cut to required lengths.

Pipes must be cut at right angles and deburred to

ensure a good smooth fit with sufficient overlap for the

glue joints. Correct any interference conditions.

8. Provide support hangers for horizontal vent piping every

1.2m (4 ft.) to prevent sagging and stress. Provide a

minimum of 3mm (1/8 in.) rise per 1.2m (4 ft.) of vent

piping to ensure adequate drainage. Horizontal vent

piping must not sag to form valleys where condensate

may collect. Vertical venting shall be supported every

1.5m (5 ft.). Use appropriate support straps and vibra-

tion isolators (foam pads) on straight sections only. Do

not use elbows as support points. Allow sufficient clear-

ance for expansion and contraction of the venting sys-

tem.

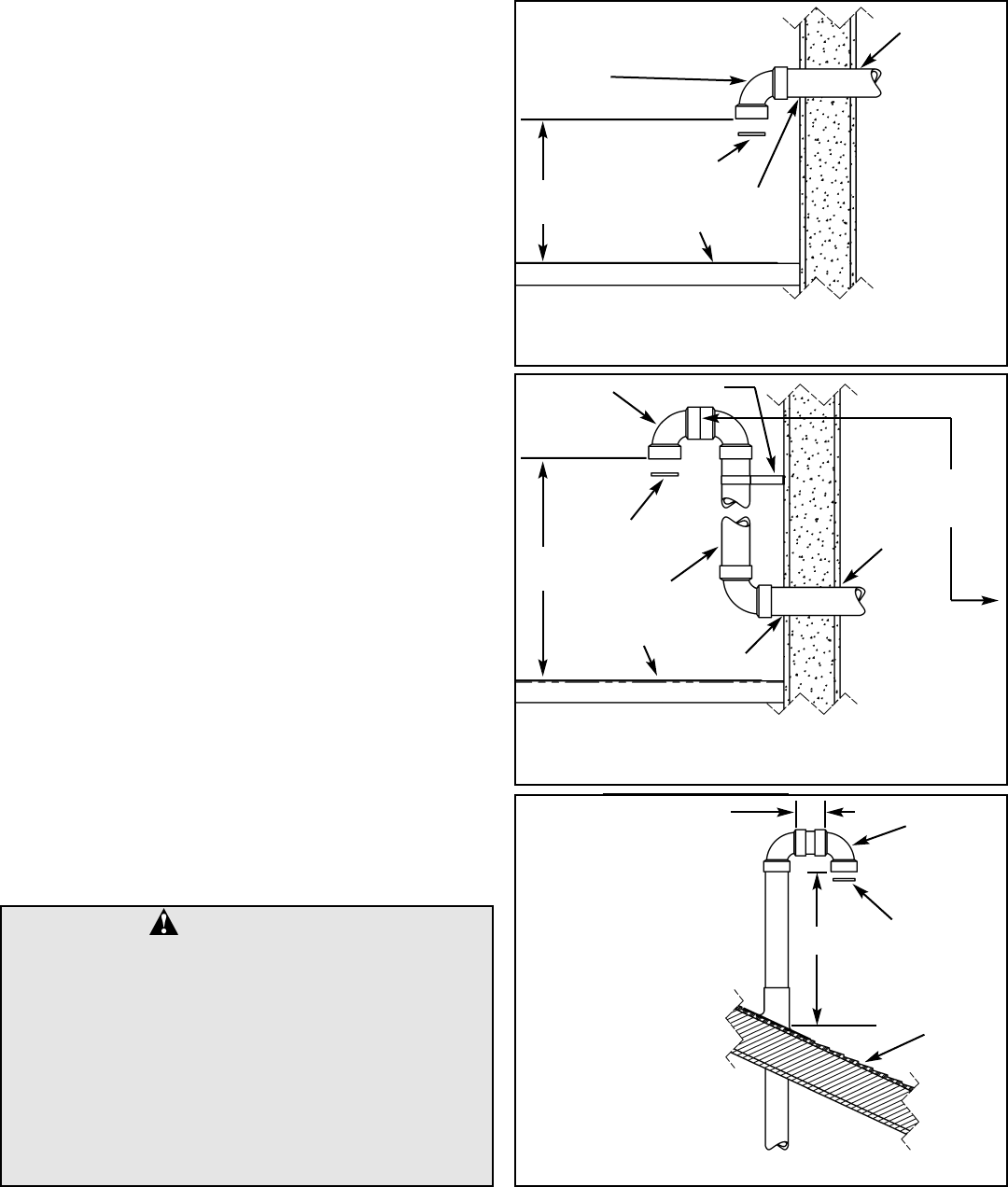

9. At the point where the vent pipe exits the building, cut a

65mm (2-1/2 in.) hole for 50mm (2 in.) venting or a

90mm (3-1/2 in.) hole for 76mm (3 in.) venting.

10. Insert the vent piping through this hole and secure into

position. Connect the vent pipe to the end termination

elbow as shown in Figures.9-11.

– 13 –

CAUTION:

Use of Solvent Cement and Primer

• Use only in well-ventilated areas.

• Do not use near flame or open fire.

• Use only the Solvent Cement and Primer

appropriate for the venting material being

used.

• Solvent cements for plastic pipe are flam-

mable liquids and must be kept away from

all sources of ignition.

SEALANT

SEALANT

GROUND LEVEL

OR MAXIMUM

SNOW LINE*

Figure 9 Vent Termination Exterior Installation

RODENT SCREEN

(INSTALL INTO

ELBOW)

* WHERE SNOW COVER IS NORMAL DURING WINTER, ENSURE

SUFFICIENT VENT CLEARANCE TO PREVENT BLOCKAGE OR ICE BUILDUP.

300mm

(12 in.)

MIN.

ATTACH 90°

TERMINATION

ELBOW

VENT PIPING MAY BE

SLOPED IN ANY

DIRECTION, AS LONG

AS A WATER TRAP IS

NOT CREATED IN

THE VENTING SYS-

TEM. THE SLOPE

SHOULD BE KEPT TO

A MINIMUM SO AS

NOT TO EXERT ANY

UNDUE STRESS ON

THE PIPE.

BRACKET

VENT

RISER

SEALANT

SEALANT

ATTACH 90°

TERMINATION

ELBOW

GROUND LEVEL

OR MAXIMUM

SNOW LINE*

Figure 10 Installation Of Fabricated Vent Riser.

RODENT

SCREEN

(INSTALL

INTO

ELBOW)

VENT PIPING TO BE

SLOPED (DOWN)

TOWARD HEATER TO

PREVENT WATER

FROM COLLECTING.

EQUIVALENT

VENT LENGTH

MEASURED FROM

THIS POSITION

* WHERE SNOW COVER IS NORMAL DURING WINTER, ENSURE

SUFFICIENT VENT CLEARANCE TO PREVENT BLOCKAGE OR ICE BUILDUP.

300mm

(12 in.)

MIN.

TERMINATION

MAY BE 90°

ELBOW

76mm (3 in.)

MIN. LENGTH

ROOF

LINE

Figure 11 Vertical Venting

A VENT USED IN A SPECIAL

VENTING SYSTEM WITH

POSITIVE VENT PRESSURE

AND PASSING THROUGH A

ROOF SHALL EXTEND AT

LEAST 450mm (18 in.)

ABOVE THE HIGHEST

POINT WHERE IT PASSES

THROUGH THE ROOF SUR-

FACE AND ANY OTHER

OBSTRUCTION WITHIN A

HORIZONTAL DISTANCE OF

450mm (18 in.). A VERTICAL

VENTING SYSTEM MUST

BE SUPPORTED EVERY

1.5m (5 ft.).

RODENT

SCREEN

(INSTALL

INTO

ELBOW)

450mm

(18 in.)