10 309098

Operation

Shut Down.

1. For normal system shut down, disconnect power

to lubricator controller (J) by turning off the ignition

switch, and turn off hydraulic supply by closing the

ball valve (Fig. 2, item AA).

CAUTION

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed, possibly damaging pump. If your pump

accelerates quickly, or is running too fast, stop the

pump immediately and check the fluid supply.

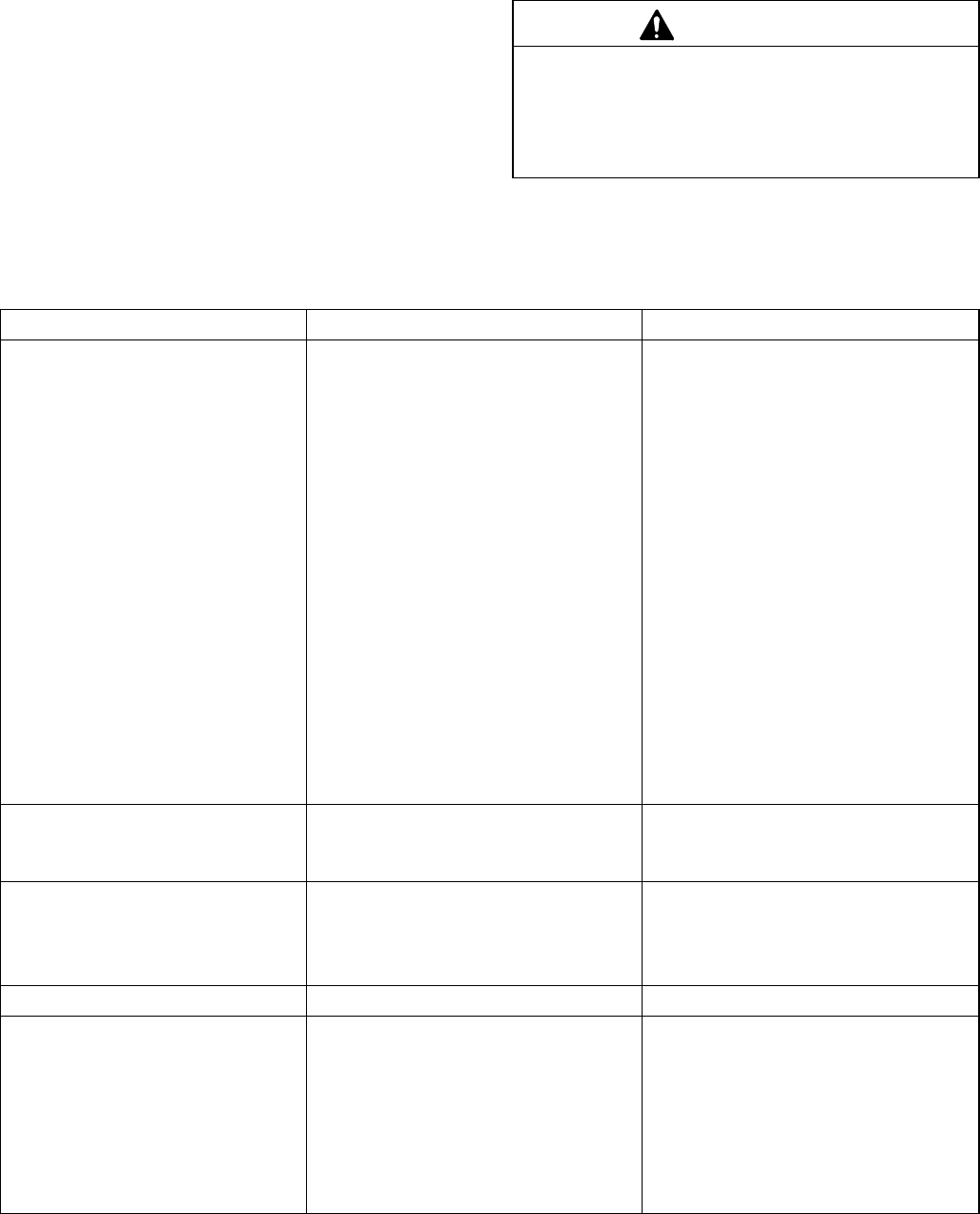

Troubleshooting

Problem Cause Solution

System does not build sufficient

pressure

Pump malfunction

Pump turned off too soon

Solenoid malfunction

Too low or no hydraulic supply

Vent valve seal failure

Vent valve needle/seat failure

Reservoir out of grease

Broken or leaky supply/branch line

Injector failure

Pressure in tank line too high due to

restrictions in tank line or plumbing

too small

Refer to manual 308156

Increase timer “pump on” setting

Increase hydraulic flow rate to pump

Repair or replace

Turn pressure up or supply on

Replace seal

Replace needle and seat

Fill reservoir

Tighten connections and/or replace

line(s)

Repair or replace

Remove tank line restrictions

Use larger plumbing

Lubricant dispensed from pres-

sure relief valve

System pressure set too high Decrease hydraulic pressure to pump

Pump runs too fast Reservoir out of lubricant

Pump cavitation

Leak in distribution system

Fill reservoir

Install a follower plate

Repair leak

Lubricant coming out of breather Reservoir overfilled Drain lubricant until overflow stops

Pump will not start No hydraulic supply

Solenoid malfunction

No electrical supply to lubrication

controller

Lubrication controller malfunction

Pump malfunction

Verify/check hydraulic supply

Replace solenoid

Turn on electrical supply

Refer to controller manual 308950

Refer to pump manual 308156