46

COMFORTNET™ SYSTEM

Submenu Item User Modifiable Options Comments

Cool Airflow (CL CFM) 18, 24, 30, 36, 42, 48, or 60, default

is 18

Selects the airflow for the non-CT

compatible single stage AC unit

Cool Airflow Trim (CL TRM) -10% to +10% in 2% increments,

default is 0%

Selects the airflow trim amount for the non-

CT compatible single stage AC unit

Cool Airflow Profile (CL PRFL) A, B, C, or D, default is A Selects the airflow profile for the non-CT

compatible single stage AC unit

Cool ON Delay (CL ON) 5, 10, 20, or 30 seconds, default is

5 seconds

Selects the indoor blower ON delay for the

non-CT compatible single stage AC unit

Cool OFF Delay (CL OFF) 30, 60, 90, or 120 seconds, default

is 30 seconds

Selects the indoor blower OFF delay for the

non-CT compatible single stage AC unit

NON-COMM (APPLIES ONLY TO A CT COMPATIBLE FURNACE MATCHED

WITH A NON-CT COMPATIBLE SINGLE STAGE AIR CONDITIONER)

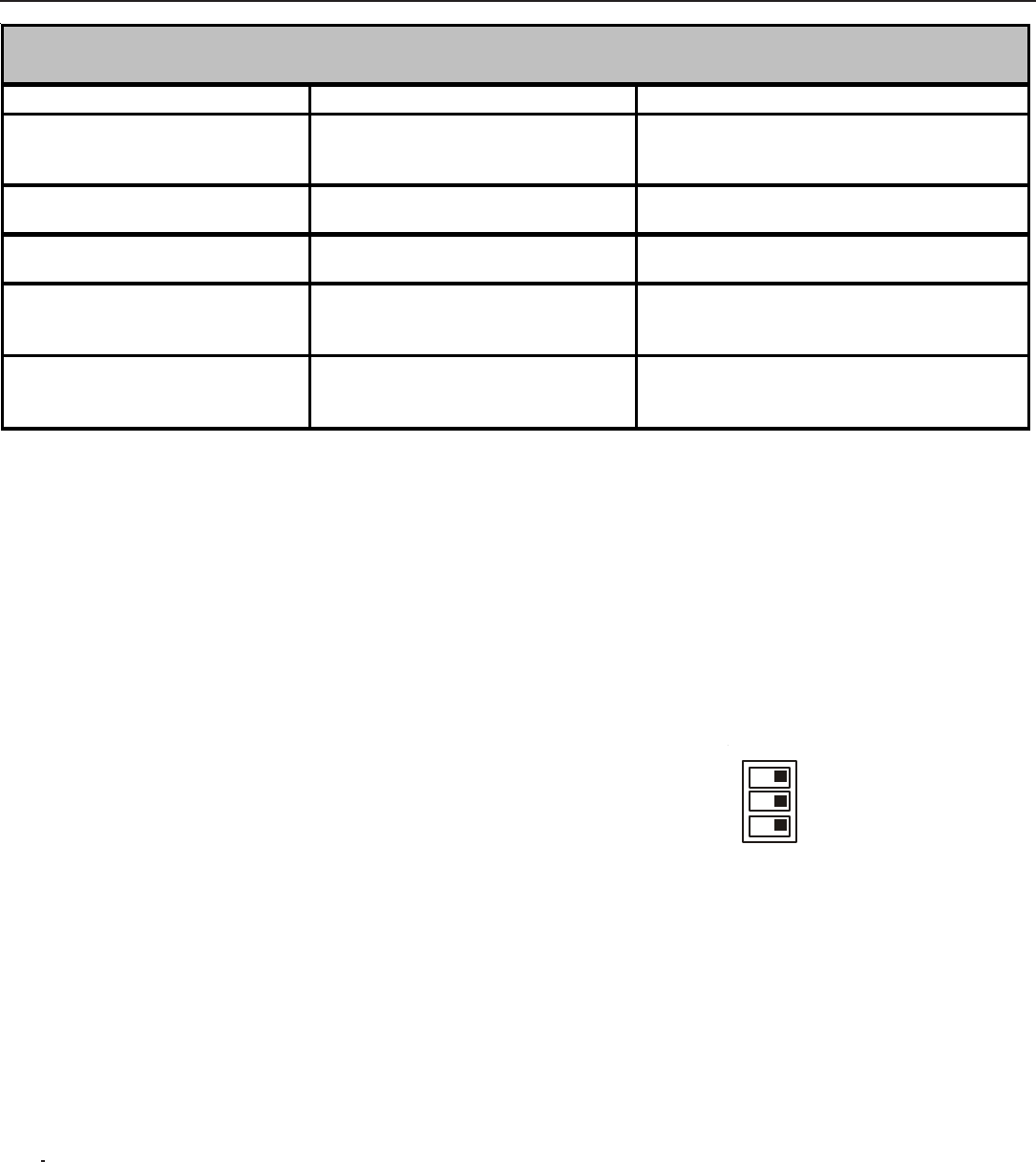

The indoor control is equipped with a bank of three dipswitches

that provide biasing and termination functions for the communi-

cations transmission lines. The outdoor control in the CT™

compatible unit is equipped with a bank of two dipswitches that

provide termination functions for the communications transmis-

sion lines. Communications errors will result if these switches

are not correctly set. The table below indicates the switch posi-

tion for the bias and termination dipswitches along with the ex-

pected voltages. Note that the ON position is the correct posi-

tion for all bias and termination dipswitches.

1

2

ONOFF

3

BIAS

BIAS

TERM

Indoor Unit BIAS and TERMINATION Dipswitches

The ComfortNet system is a fully communicating system, and

thus, constitutes a network. Occasionally the need to trouble-

shoot the network may arise. The integrated furnace control has

some on-board tools that may be used to troubleshoot the net-

work. These tools are: red communications LED, green receive

(Rx) LED, and learn button.

• Red communications LED – Indicates the status of the

network. The table below indicates the LED status and

the corresponding potential problem.

• Green receive LED – Indicates network traffic. The table

below indicates the LED status and the corresponding

potential problem.

• Learn button – Used to reset the network. Depress the

button for approximately 2 seconds to reset the network.

THERMOSTAT MENU

If this furnace is installed with a CT compatible heat pump, the

system is recognized as a dual fuel system. The balance point

temperature should be set via the thermostat advanced menu.

Navigate to the THERMOSTAT menu. Press the INSTALLER

CONFIG key. Navigate to the SETUP menu and press the IN-

STALLER CONFIG button. Navigate to dF BAL PNT. Adjust

the dual fuel system balance point using the back/forward ar-

rows.

DIAGNOSTICS

Accessing the furnace’s diagnostics menu provides ready ac-

cess to the last six faults detected by the furnace. Faults are

stored most recent to least recent. Any consecutively repeated

fault is stored a maximum of three times. Example: A clogged

return air filter causes the furnace limit to trip repeatedly. The

control will only store this fault the first three consecutive times

the fault occurs. Navigate to the diagnostics menu as described

above in Accessing and Navigating the Advanced Features Menus.

NOTE: It is highly recommended that the fault history be cleared

when performing maintenance or servicing the furnace.

NETWORK TROUBLESHOOTING

Communications is achieved by taking the difference between

two dc signals. The signals and transmission lines are referred

to as “data 1” and “data 2”. Each transmission line is biased to

approximately 2.5Vdc. During data reception/transmission, the

data lines vary between +5V and ground. (When data 1 is in-

creasing towards +5V, data 2 is decreasing towards ground and

when data 1 is decreasing towards ground, data 2 is increasing

towards +5V. Typically, the data 1 line is approximately 2.6Vdc

and the data 2 transmission line is approximately 2.3Vdc. The

voltage difference between data 1 and data 2 is typically 0.2 to

0.6 Vdc.