43

COMFORTNET™ SYSTEM

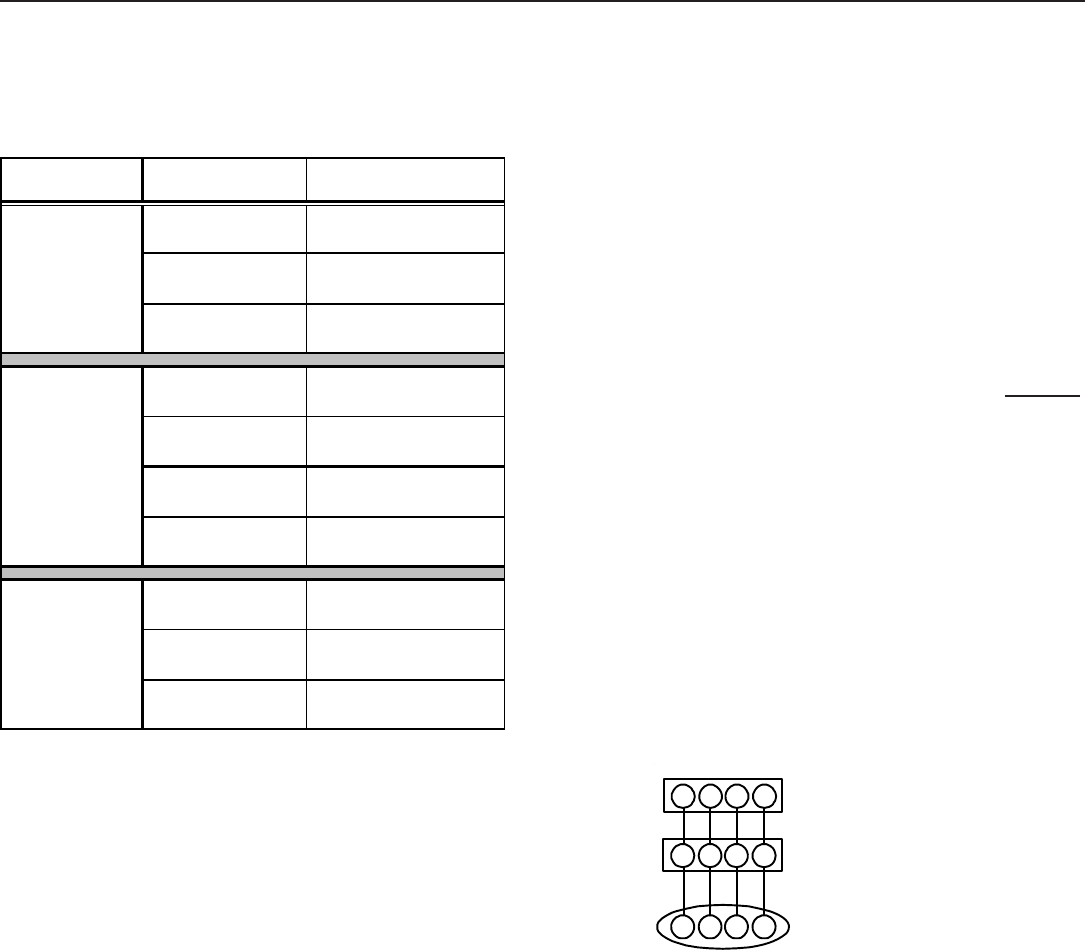

demand and transmits the demand along with a fan request

to the indoor unit. The indoor unit then sends the demand

to the ECM motor. The table below lists the various

ComfortNet™ systems, the operating mode, and airflow

demand source.

System

System Operating

Mode

Airflow Demand Source

Cooling Air Conditioner

Heating Furnace

Continuous Fan Thermostat

Cooling Heat Pump

Heat Pump Heating

Only

Heat Pump

Auxiliary Heating Furnace

Continuous Fan Thermostat

Cooling Furnace

Heating Furnace

Continuous Fan Thermostat

Furnace + Non-

Comm 1stg Air

Conditioner

Air Conditioner +

Furnace

Heat Pump +

Furnace

For example, assume the system is an air conditioner

matched with a furnace. With a call for low stage cooling,

the air conditioner will calculate the system’s low stage

cooling airflow demand. The air conditioner will then send a

fan request along with the low stage cooling airflow demand

to the furnace. Once received, the furnace will send the low

stage cooling airflow demand to the ECM motor. The ECM

motor then delivers the low stage cooling airflow. See the

applicable ComfortNet™ air conditioner or heat pump

installation manual for the airflow delivered during cooling or

heat pump heating.

In continuous fan mode, the CTK01AA thermostat provides

the airflow demand. The thermostat may be configured for

a low, medium, or high continuous fan speed. The low,

medium, and high fan speeds correspond to 25%, 50%,

and 75%, respectively, of the furnaces’ maximum airflow

capability. During continuous fan operation, the thermostat

sends a fan request along with the continuous fan demand

to the furnace. The furnace, in turn, sends the demand to

the ECM motor. The ECM motor delivers the requested

continuous fan airflow.

FOSSIL F UEL A PPLICATIONS

This furnace can be used in conjunction with a CT™ compatible

heat pump in a fossil fuel application. A fossil fuel application

refers to a combined gas furnace and heat pump installation which

uses an outdoor temperature sensor to determine the most cost

efficient means of heating (heat pump or gas furnace). When

used with the CTK01AA thermostat, the furnace/heat pump

system is automically configured as a fossil fuel system. The

balance point temperature may be adjusted via the CTK01AA

thermostat advanced user menus (see CTK01AA instructions

for additional information).

CTK01AA WIRING

NOTE: Refer to Electrical Connections for 115 volt line connections

to the furnace.

NOTE: A removable plug connector is provided with the control to

make thermostat wire connections. This plug may be removed,

wire connections made to the plug, and replaced. It is

strongly

recommended that multiple wires into a single terminal be twisted

together prior to inserting into the plug connector. Failure to do so

may result in intermittent operation.

Typical 18 AWG thermostat wire may be used to wire the system

components. One hundred (100) feet is the maximum length of

wire between indoor unit and outdoor unit, or between indoor unit

and thermostat. Wire runs over (100) feet require larger gauge

wire.

FOUR-WIRE I NDOOR AND O UTDOOR W IRING

Typical ComfortNet™ wiring will consist of four wires between the

indoor unit and outdoor unit and between the indoor unit and ther-

mostat. The required wires are: (a) data lines, 1 and 2; (b) thermo-

stat “R” (24 VAC hot) and “C” (24 VAC common).

12RC

12RC

CTK01AA

Thermostat

CT™ Compatible Furnace

Integrated Control Module

CT™ Compatible AC/HP

Integrated Control Module

12RC

System Wiring using Four-Wires

TWO-WIRE O UTDOOR, FOUR-WIRE I NDOOR W IRING

Two wires can be utilized between the indoor and outdoor units.

For this wiring scheme, only the data lines, 1 and 2, are needed

between the indoor and outdoor units. A 40VA, 208/230 VAC to

24VAC transformer must be installed in the outdoor unit to provide

24VAC power to the outdoor unit’s electronic control. The trans-

former is included with the CTK01AA kit. See kit instructions for

mounting and wiring instructions. Four wires are required between

the indoor unit and thermostat.

NOTE: Use of the CTK01AA transformer is recommended if

installing a dual fuel/fossil fuel system. Failure to use the

transformer in the outdoor unit could result in over loading of the

furnace transformer.