12

Installation Instructions

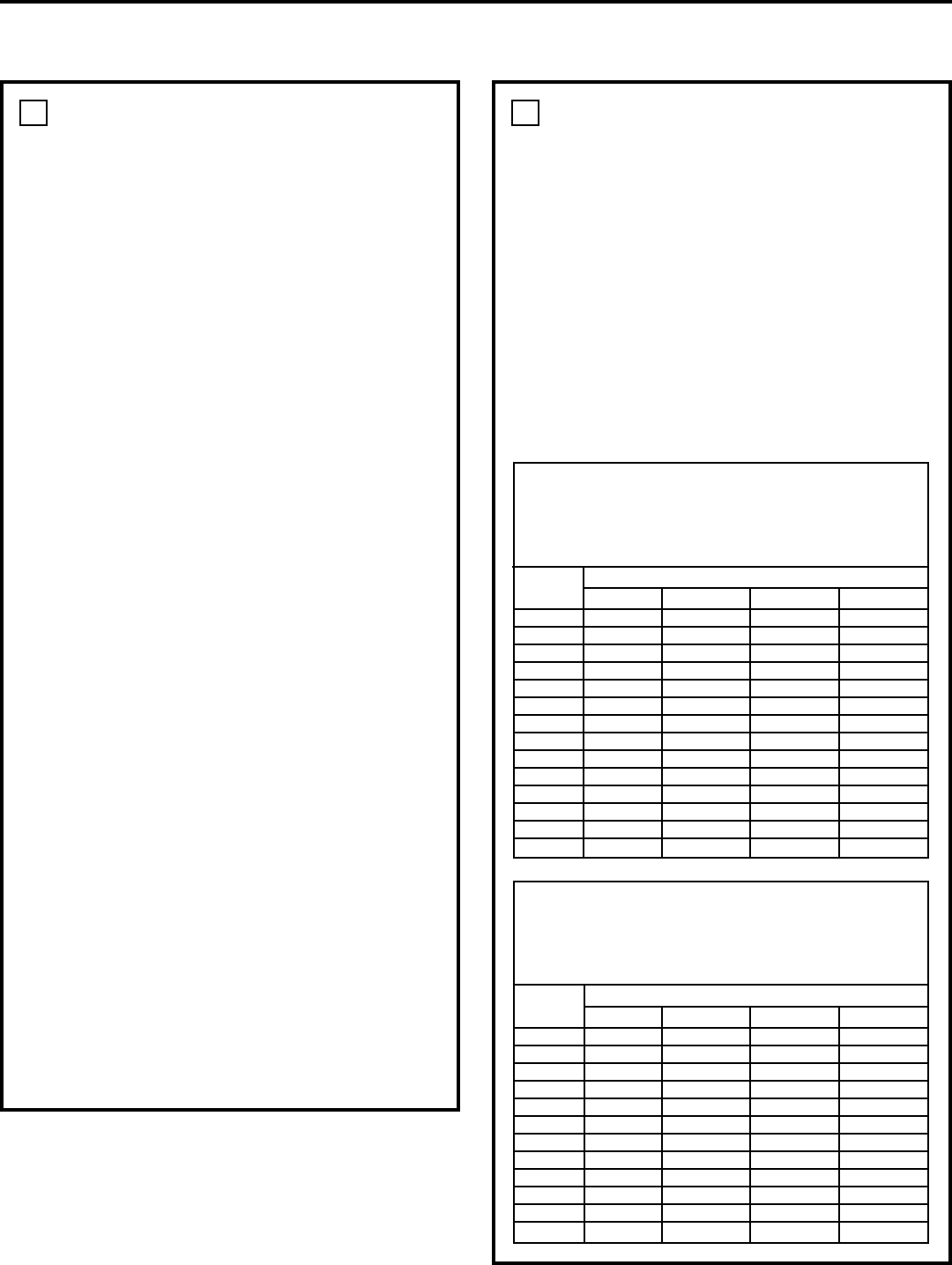

GAS PIPING (cont.)

PIPE SIZING PROCEDURE

The gas supply to the home must be capable

of handling the entire gas load of the home,

calculated by adding the BTU rating of each gas

appliance in the home. State and local codes must

be met, as well as utility requirements, to ensure

gas supply to the unit is adequate to meet the

rated demand. Use the charts below as a guide to

size the pipe from the utility meter to the tankless

water heater. Gas line sizing is based on gas type,

the pressure drop in the system, the gas pressure

supplied and the gas line type. Refer to the National

Fuel Gas Code, NFPA 54, and/or your local gas

provider, for proper gas line sizing.

1

GAS PIPING

GENERAL INSTRUCTIONS

• Make sure gas supply is off prior to making

any connections to the water heater. A manual

gas control valve, provided with this water

heater, must be placed in the gas supply line

to the water heater. A union can be used on

the connection above the shut-off valve for

the future servicing or disconnection of the unit.

• Check the type of gas and the gas inlet pressure

before connecting the water heater. If the water

heater is not of the gas type that the building is

supplied with, DO NOT connect the water heater.

Contact the dealer for the proper unit to match

the gas type.

• Check the gas supply pressure immediately

upstream at a location provided by the gas

company. Supplied gas pressure must be within

the limits shown in the Specifications section.

• Before placing the appliance in operation, all

joints, including the heater, must be checked for

gas tightness by means of leak detector solution,

soap and water or an equivalent nonflammable

solution, as applicable. (Since some leak test

solutions, including soap and water, may cause

corrosion or stress cracking, the piping shall

be rinsed with water after testing, unless it has

been determined that the leak test solution is

noncorrosive.)

• Always use approved connectors to connect the

unit to the gas line. Always purge the gas line of

any debris before connection to the water heater.

• The gas supply line shall be gas tight, sized

and so installed as to provide a supply of gas

sufficient to meet the maximum demand of the

heater and all other gas-consuming appliances

at the location without loss of pressure.

• Any compound used on the threaded joint of

the gas piping shall be a type which resists the

action of liquefied petroleum gas (propane/LPG).

• Refer to an approved pipe sizing chart

if in doubt about the size of the gas line.

1

CONNECTING THE WATER HEATER TO GAS AND WATER

PIPE SIZING TABLE – NATURAL GAS

cubic feet per hour Schedule 40 Metallic Pipe

Inlet Pressure: less than 2 psi (55 inches W.C.)

Pressure Drop: 0.3 inches W.C.

Specific Gravity: 0.60

PIPE SIZE (INCHES)

Length 3/4 11

1

/4 1

1

/2

10 273 514 1060 1580

20 188 353 726 1090

30 151 284 583 873

40 129 243 499 747

50 114 215 442 662

60 104 195 400 600

70 95 179 368 552

80 89 167 343 514

90 83 157 322 482

100 79 148 304 455

125 70 131 269 403

150 63 119 244 366

175 58 109 224 336

200 54 102 209 313

PIPE SIZING TABLE – PROPANE GAS

cubic feet per hour Schedule 40 Metallic Pipe

Inlet Pressure: 11.0 inches W.C.

Pressure Drop: 0.5 inches W.C.

Specific Gravity: 1.50

PIPE SIZE (INCHES)

Length 1/2 3/4 11

1

/4

10 291 608 1150 2350

20 200 418 787 1620

30 160 336 632 1300

40 137 287 541 1110

50 122 255 480 985

60 110 231 434 892

80 101 212 400 821

100 94 197 372 763

125 89 185 349 716

150 84 175 330 677

175 74 155 292 600

200 67 140 265 543